Wire cutting services

High precision, with a tolerance of up to+/-. 0001 "

Automatic tapping enhances thermal stability

Turnaround time as low as 24 hours

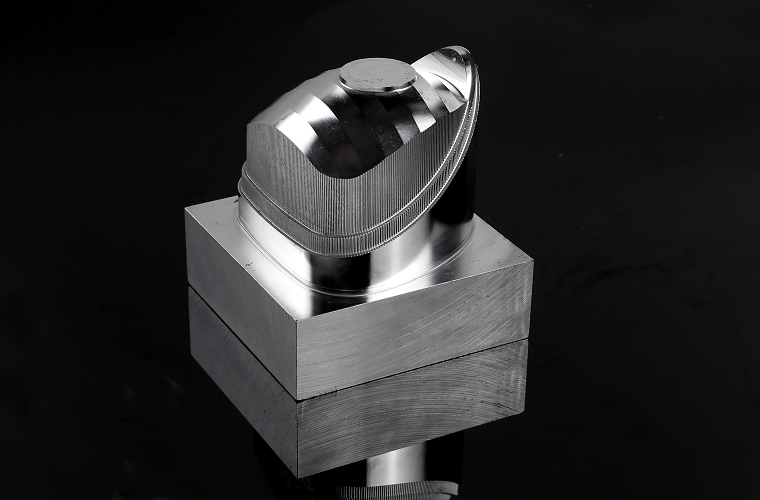

Wire cutting discharge machining (discharge machining) can be called a miracle of subtractive manufacturing. This is a kind of electric spark molding and engraving conductive material technology. What is unique about wire cut discharge machining? Its unparalleled precision. The process uses fine electrically charged wires (usually brass or copper), guided by an advanced CNC system, which carefully corrodes the material to achieve complex and precise designs.

As a leading manufacturer of vacuum casting, Youxenda provides low-cost manufacturing of high-quality plastic parts. This technology eliminates the need for expensive upfront investment. Our vacuum casting services provide a complete solution for creating high-quality prototypes and small-volume production parts.

Why Choose Our Wire Cutting Services

In precision manufacturing, wire cutting stands out as a process that provides high precision and complex details. For companies looking for the best wire cutting services, Youxingda is the first choice.

The most advanced technology

Youxingda uses top-of-the-line machinery that is regularly updated to ensure that customers receive workpieces processed in accordance with the highest standards of precision and accuracy.

Fast turnaround time

With years of experience, our experts consistently deliver products that exceed our customers' expectations, reflecting our mastery of manufacturing complexity.

Fast turnaround time

In our fast-paced world, we rely on our efficient processes and dedicated team to ensure fast project turnaround without compromising quality.

Wire-cut electrical discharge machining for prototyping and production

Youxingda is a comprehensive, integrated manufacturing platform designed to meet all the needs of your wire cutting project.

Rapid prototyping

Utilize our strong manufacturing capabilities to deliver prototypes quickly and with high quality. Using the latest technology, we ensure fast and accurate production, accelerating your time from testing to market launch.

Production capacity: 20-500

Delivery time: within 10 working days

Small batch manufacturing

Our precision machining is suitable for small batch production, providing fast delivery and unparalleled accuracy. We ensure that your project meets high-quality standards with reduced costs.

Production capacity:500-1000

Delivery time:Within 15 working days

Mass production

Youxingda is capable of handling large-scale production orders. This means they can efficiently produce a large number of precision machined parts without affecting quality or accuracy.

Production capacity: 1000+

Delivery time: Within 20 working days

WEDM Part Size Standard

Product Model

Small parts (mm)

Medium Parts (mm)

Large Parts (mm)

Maximum length

50

100

500

Maximum width

30

70

300

Maximum height

10

40

150

Minimum thickness

0.5

1.0

5.0

Tolerance

±0.005

±0.01

±0.03

Metal for wire cutting

Our experts at Youxingda are proud of their ability to handle a variety of materials that can open up a world of possibilities for your project. Some of the materials that can be processed are:

Aluminum material

Aluminum material

It is a popular choice for industries looking for lightweight, durable components. We can accurately cut and shape aluminum parts in aerospace, automotive, electronics and other fields.

Copper

Copper

Copper has excellent electrical and thermal conductivity, making it an indispensable material for electrical components, connectors and conductive components. Our expertise ensures that copper parts are made with the highest precision to ensure that the final part maintains its core characteristics.

Brass

Brass

With its attractive beauty and excellent machining properties, brass is widely used in decorative parts, electronic products and pipe fittings. Our wire cutting process ensures the production of complex and precise brass parts in the shortest delivery time.

Iron piece

Iron piece

From tool steel to stainless steel, our wire cutting services can handle a wide range of steel alloys. We deliver precise and consistent results to meet the requirements of industries such as automotive, tool and tooling, and precision engineering.

Titanium

Titanium

As a challenging material to process, titanium requires specialized methods to achieve the best results. Our wire cutting expertise enables us to process titanium components with the highest precision. This makes it an excellent choice for aerospace, medical and performance engineering applications.

Bronze

Bronze

Bronze is valued for its unique combination of strength and corrosion resistance, making it suitable for bearings, gears and art applications. Since bronze is expensive, any waste can have a significant impact on cost. Our wire cutting technology ensures excellent results, minimal waste and minimal turnaround time.

Other conductive materials

Other conductive materials

Our wire cutting capabilities extend beyond the range of common materials. We are proficient in the processing of precious metals such as gold and silver, as well as various nickel alloys. Regardless of your specific material requirements, we have the expertise to deliver superior results.

Surface Finishing of Wire Cutting

Name

Materials

Color

Texture

Link

anodic oxidation

Aluminum material

Transparent, black, gray, red, blue, gold

Smooth, matte finish

powder coating

Aluminum, stainless steel, steel

Black, any RAL code or Pantone number

Gloss or semi-gloss

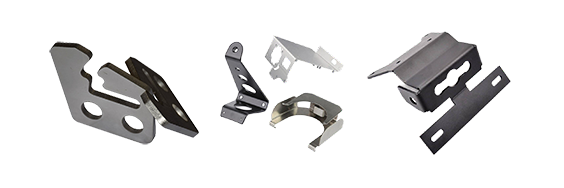

Application of Wire Cutting Parts

Global experience is crucial. Our loyal RapidDirect team has the right skills and expertise to meet a wide range of industrial needs. Some of the industries we work with are:

Aerospace: Use our wire cutting services to achieve lightweight and high-strength components without compromising strict aviation standards.

Medical: Give us critical medical components that require the highest levels of accuracy and cleanliness.

Automotive: Improve the performance and durability of your auto parts through our precise processing.

Electronics: Accuracy is the key to the electronics industry, and we ensure that your components meet the highest standards.

Manufacturing: Get complex and precise tooling and mold components for your manufacturing process.

Energy: Optimize your energy components with our wire cutting services to ensure efficiency and reliability.

wire cutting machining

It is important to remember that wire cutting is an erosion process, not other subtractive processes that rely on cutting. Therefore, it has different surface characteristics, which are usually dependent on the number of passes (iterative cuts) to obtain the best finish. Our practice is as follows.

First pass (rough cut)

A rougher surface finish can quickly achieve a design with a tolerance of +/- .002. About 90% of wire cut parts only need the first pass because tolerances are acceptable for many applications and surface finishing requirements.

Second pass (finishing)

For more advanced applications, the finer second pass can achieve a tolerance of up to/- 0.0005 "and a surface finish of 72 µin, which is almost indistinguishable to the naked eye.

Third pass (more detailed details)

This is the most delicate cut and the finest finish required for highly sensitive applications such as medical equipment and aerospace components. The third pass can reduce the surface finish to 35 µin, which is beyond the needs of many wire cutting applications.