CNC milling services

Instant CNC quotation and free DFM

A strict tolerance of 0.01 millimeters

The fastest milling time for parts is 1 day

3. 4. 5-axis milling

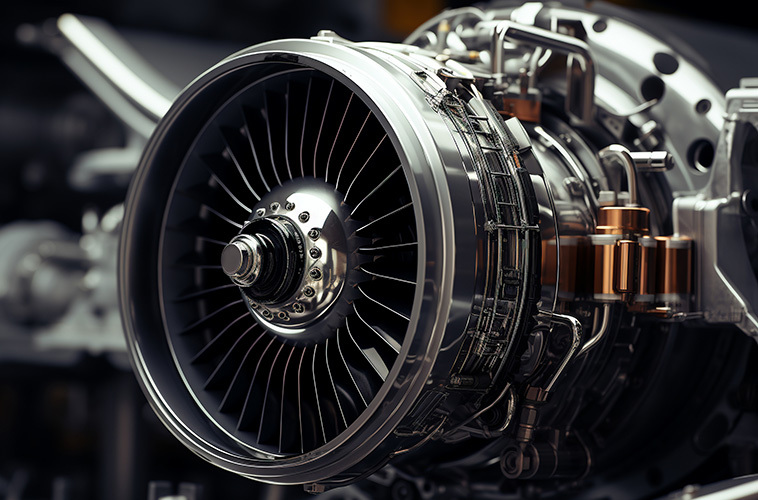

Youxingda 3 to 5 Axis CNC Milling Services

From the basics of 3-axis to complex 5-axis projects, our precision CNC milling brings your designs to life with unparalleled precision and craftsmanship.

3-axis CNC milling

4-axis CNC milling

5-axis CNC milling

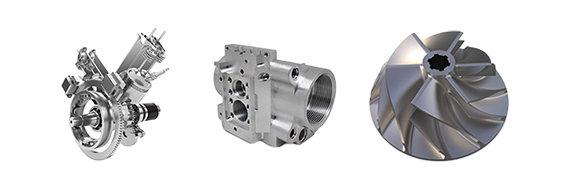

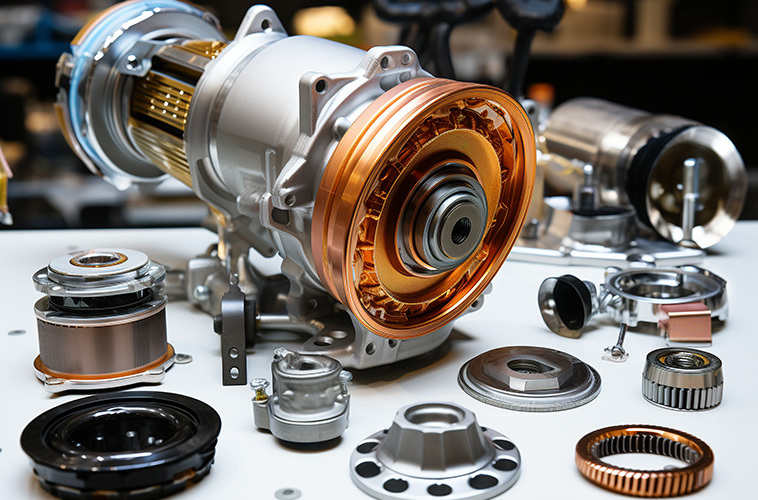

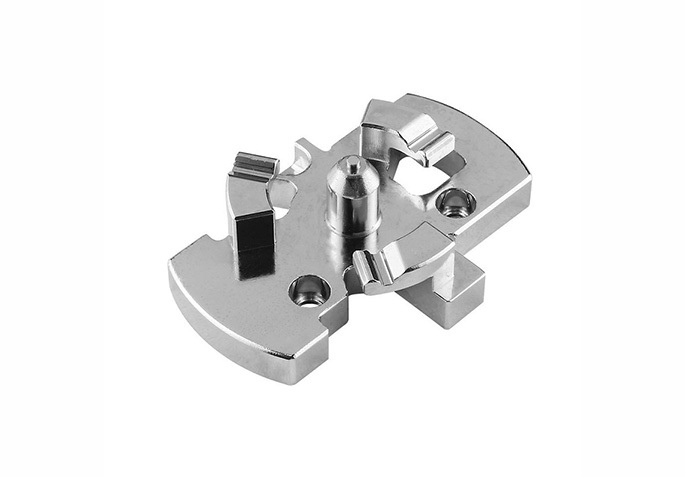

CNC Milling Parts Gallery

View our informative gallery showcasing precision ground prototypes and parts from our valued customers.

CNC milling part 01

CNC milling part 02

CNC milling parts03

CNC milling parts04

Precision CNC Milling Solutions: From Concept to Finish

Our journey-driven CNC milling will guide you from the initial idea all the way to the end product that is perfectly produced. Every step is precise and careful.

Rapid prototyping

Use Youxenda to quickly convert CAD designs into final CNC milling prototypes. Test and refine your concepts, reduce costly milling errors, and accelerate time to market.

Bridge making

Seamless transition from prototype production to CNC milling production. Ensure a smooth transition phase, reduce expansion risk and maintain consistent quality with Youxingda's Bridge Production.

On-demand production

Meet market demand with on-demand precision CNC milling. Youxingda ensures that you complete tasks on time, effectively manage inventory and accurately produce high-quality components when needed.

CNC Milling Tolerances

Youxingda ensures accuracy through our CNC milling tolerance standards. We are committed to accurate measurement, consistent, high-quality results for our customers, and optimized for search visibility. Our standard tolerances for CNC milling are ISO 2768-m for metals and ISO 2768-c for plastics.

Type

Tolerance

Linear Dimensions

/- 0.01mm

/- 0.001 inches

Bore diameter (unreamed)

/- 0.025mm

/- 0.001 inches

Shaft diameter

950*550*480mm

37.0*21.5*18.5 inches

Part Size Limits

950*550*480mm

37.0*21.5*18.5 inches

CNC Milling Part Material

At Youxinda, our CNC milling services offer a wide range of materials to ensure precision and durability. This wide selection enables our customers to provide the best choice for their unique projects, thereby improving the quality and performance of their products.

Aluminum material

Aluminum material

Aluminum is a very ductile metal, so it is easy to process. The material has a good strength-to-weight ratio, and there are many types to choose from, suitable for various applications.

Price: $

Delivery time: <10 days

Tolerance: ± 0.125mm (± 0.005 inches)

Maximum part size: 200 x 80 x 100 cm

Copper

Copper

Copper has excellent thermal conductivity, electrical conductivity and plasticity. It also has high ductility, corrosion resistance and is easy to weld.

Price: $

Delivery time: <10 days

Chamber wall thickness: 0.75mm

Tolerance: ± 0.125mm (± 0.005 inches)

Maximum part size: 200 x 80 x 100 cm

Brass

Brass

Brass has desirable properties for a variety of applications. It has low friction, excellent conductivity and golden (brass) appearance.

Price: $

Delivery time: <10 days

Chamber wall thickness: 0.75mm

Tolerance: ± 0.125mm (± 0.005 inches)

Maximum part size: 200 x 80 x 100 cm

Stainless Steel

Stainless Steel

Stainless steel is a mild steel with properties sought after in many industrial applications. Stainless steel typically contains at least 10% chromium (by weight).

Price: $$

Delivery time: <10 days

Chamber wall thickness: 0.75mm

Tolerance: ± 0.125mm (± 0.005 inches)

Maximum part size: 200 x 80 x 100 cm

Titanium

Titanium

Titanium has many material properties that make it an ideal metal for demanding applications. These properties include excellent corrosion resistance, chemical resistance and resistance to extreme temperatures. The metal also has an excellent strength-to-weight ratio.

Price: $$$

Delivery time: <10 days

Chamber wall thickness: 0.75mm

Tolerance: ± 0.125mm (± 0.005 inches)

Maximum part size: 200 x 80 x 100 cm

Surface treatment of CNC milling

Get quality surface finishing of custom CNC milled parts to eliminate aesthetic defects and improve the appearance of the product. We also provide rigid protection and additional resistance and strength for your parts through excellent surface finish.

Name

Product Description

Materials

Color

Texture

Link

anodic oxidation

Anodizing improves corrosion resistance, enhances wear resistance and hardness, and protects the metal surface. Widely used in mechanical parts, aircraft, auto parts, precision instruments, etc.

Aluminum material

Transparent, black, gray, red, blue, gold

Smooth, matte finish

Sand blasting

The surface of the parts after sandblasting is smooth and has a matte texture. It is mainly used for vision applications and can be followed by other surface treatments.

ABS, aluminum, brass, stainless steel, steel

Not applicable

Matte

powder coating

A powder coating is a coating that is applied in the form of a free-flowing dry powder. Unlike traditional liquid coatings, which are delivered by evaporation of solvents, powder coatings are typically electrostatically sprayed and then cured under heat or ultraviolet light.

Aluminum, stainless steel, steel

Black, any RAL code or Pantone number

Gloss or semi-gloss

Electroplating

The plating may be functional, decorative or corrosion-related. This process is used by many industries, including the automotive industry, where chrome plating of steel automotive parts is common.

Aluminum, steel, stainless steel

Not applicable

smooth gloss

Polishing

Polishing is the process of creating a smooth and shiny surface through physical friction or chemical interference of parts. This process produces a surface with significant specular reflection, but in some materials can reduce diffuse reflection.

Aluminum, Brass, Stainless Steel, Steel

Not applicable

Smooth

Polishing

Brushing is a surface treatment process in which an abrasive belt is used to draw marks on the surface of a material, usually for aesthetic purposes.

ABS, aluminum, brass, stainless steel, steel

Not applicable

Smooth

Why Choose Our CNC Milling Services

With Youxingda's CNC milling services, you're investing in more than just machinery. You will have the promise of impeccable accuracy, a strict schedule and the support of experienced professionals.

Milling parts with tight tolerances

Experience unparalleled precision in every task. Our advanced milling processes ensure that components adhere to tight tolerances, accurate to ± 0.01mm, for seamless assembly and operational excellence.

Fast delivery time

Speed up your manufacturing cycle. Youxingda's domestic workshops and state-of-the-art machinery ensure fast turnaround times, helping businesses stay motivated and meet critical deadlines.

Engineering support

No matter when and where you are, you can confidently navigate your CNC milling project. Our experienced experts provide insightful guidance every step of the way to optimize designs and maximize output quality.