Metal bending services

Free quotation within 1 day

The fastest delivery time is 3-5 days

What is metal bending?

Effective metal bending will apply a force large enough to exceed the yield strength of the metal to deform the material without breaking. With the different types of metal bending technologies available, you can achieve various shapes and geometries for the desired application.

Part accuracy: Through correct design and program input, the CNC machine controls the bending process to ensure that each bend is completed at an accurate angle and the correct length. This improves the accuracy and repeatability of the process.

Finish: The efficient bending process does not involve welding, ensuring that no traces are left on the custom metal parts. CNC sheet metal bending services are also compatible with various finishing processes to provide better aesthetic results.

Maximum productivity: The sheet metal bending process can be easily synchronized with automation settings, enabling bending tools to complete the process in the shortest time. This feature ensures that the output is maximized.

Cost-effectiveness: The automation of the bending process for maximum productivity in small batch production ensures cost-effectiveness. Labor demand is also low, ensuring relatively low operating costs.

Metal bending from prototyping to production

Youxingda's custom bending services can be used for a variety of applications, such as mold processing, rapid prototyping and custom manufacturing.

Functional prototype

Custom metal manufacturing can make 2D shaped contours from various metals to create functional molds for specific parts.

Rapid prototyping

Provide flexibility and precision to ensure that the preliminary version of the metal part or plate is accurate and fully functional before entering full production.

On demand production

From a wide selection of materials to curved parts manufacturing and assembly, to flexible delivery, we provide end-to-end mass production solutions.

Metal bending ability

Youxingda's sheet metal bending services follow ISO 2768 standards, ensuring that we provide our customers with quality prototypes and production parts. We combine highly advanced metal bending machines with skilled technicians to achieve precise bending. Our capabilities are suitable for rapid prototyping and production.

Standard

Product Description

Maximum part size

1.5 m × 1.5 m

metal bending force

Up to 1000 tons

Length of bending line

Up to 7200mm

Bending thickness

Up to 60mm

General tolerances

Our metal bending standards depend on ISO 2768.

Bent to edge/hole, single-sided

/- 0.254mm (/- 0.010 in)

Bending radius

equal to material thickness

Bending angle

/- 1°

curved cutting area

Up to 4000mm

Delivery time

Up to 4000mm

metal bending material

Youxinda's metal bending services are compatible with high-quality materials of many different thicknesses. Our factory has ultra-modern equipment that can bend materials with different mechanical and thermal properties. Check out some of the materials available for your project.

Aluminum material

Aluminum material

Commercially, aluminum is the most sought-after material for sheet metal fabrication. Its popularity is due to its adaptability, high thermal conductivity and low resistivity. Compared with steel (another common sheet metal material), aluminum is more cost-effective and more productive. The material also generates the least amount of waste and is easily reusable.

Subtype:

Copper

Copper

Copper is a widely used sheet metal manufacturing material in many industries because of its good ductility and ductility. Due to its excellent thermal and electrical conductivity, copper is also very suitable for sheet metal manufacturing.

Subtypes: C101, C110, C103, C27400, C28000. C36000

Iron piece

Iron piece

Steel provides many beneficial properties for industrial applications, including rigidity, longevity, heat resistance, and corrosion resistance. Steel plates are ideal for producing complex designs and parts that require extreme precision. Steel is also expensive to process and has excellent polishing properties.

Subtypes: 1018, 1020, 1025, 1045, 1215, 4130, 4140, 4340, 5140,A36,ST37

Finishing options for metal bending

Improve the surface of curved parts and finished products with excellent surface treatment options. Youxinda offers a variety of finishes to enhance the aesthetic appearance and other characteristics of the product.

Name

Product Description

Materials

Color

Texture

Link

anodic oxidation

Anodizing improves corrosion resistance, enhances wear resistance and hardness, and protects the metal surface. Widely used in mechanical parts, aircraft, auto parts, precision instruments, etc.

Aluminum material

Transparent, black, gray, red, blue, gold.

Smooth, matte finish.

Sand blasting

The surface of the parts after sandblasting is smooth and has a matte texture. Primarily for vision applications, other surface treatments can follow.

ABS, aluminum, brass, stainless steel, steel

Not applicable

Matte

powder coating

A powder coating is a coating that is applied in the form of a free-flowing dry powder. Unlike traditional liquid coatings, which are delivered by evaporation of solvents, powder coatings are typically electrostatically sprayed and then cured under heat or ultraviolet light.

Aluminum, stainless steel, steel

Black, any RAL code or Pantone number

Gloss or semi-gloss

Electroplating

The plating may be functional, decorative or corrosion-related. This process is used by many industries, including the automotive industry, where chrome plating of steel automotive parts is common.

Aluminum, steel, stainless steel

Not applicable

smooth gloss

Polishing

Polishing is the process of creating a smooth and shiny surface through physical friction or chemical interference of parts. This process produces a surface with significant specular reflection, but in some materials can reduce diffuse reflection.

Aluminum, Brass, Stainless Steel, Steel

Not applicable

Smooth

Polishing

Brushing is a surface treatment process in which an abrasive belt is used to draw marks on the surface of a material, usually for aesthetic purposes.

ABS, aluminum, brass, stainless steel, steel

Not applicable

Satin

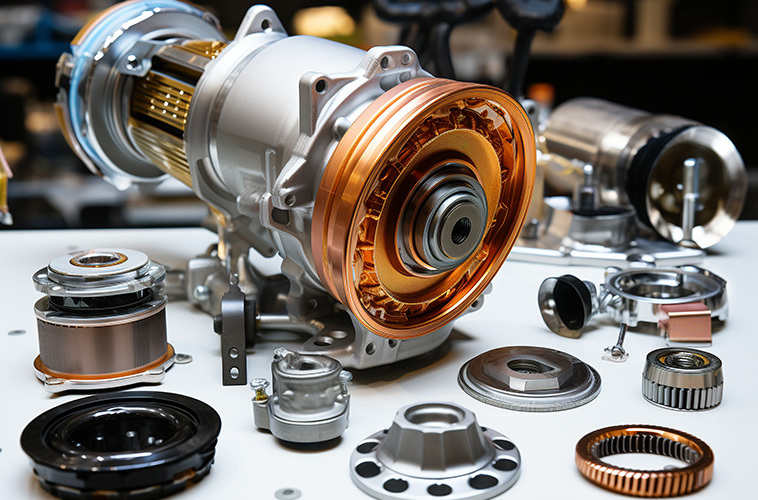

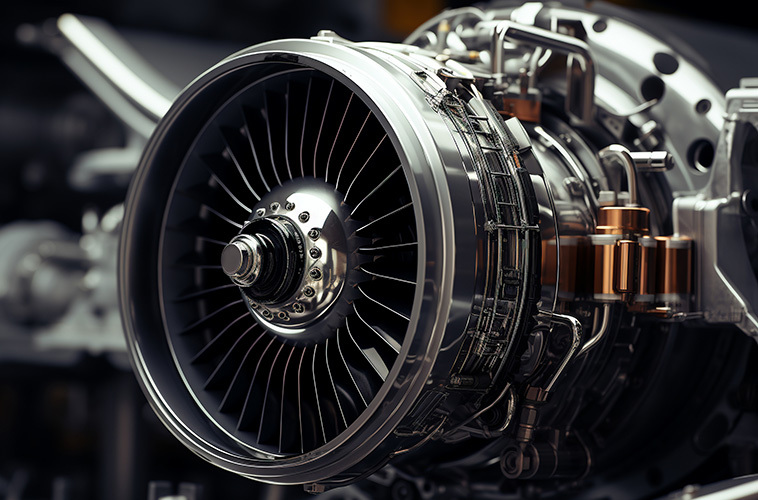

Bending parts for various applications

Use versatile and durable sheet metal bending parts to meet your wide range of applications. Youxingda is committed to metal bending projects and provides products for various industries, including:

Bending Process of Youxingda

Youxingda's sheet metal bending services are second to none. Our facilities and capabilities help us deliver the best results for our clients on every project.

Sheet Metal Bend Part Gallery

Youxingda's metal bending services continue to serve a wide range of applications in many industries. Check out some of our completed metal bending projects below.

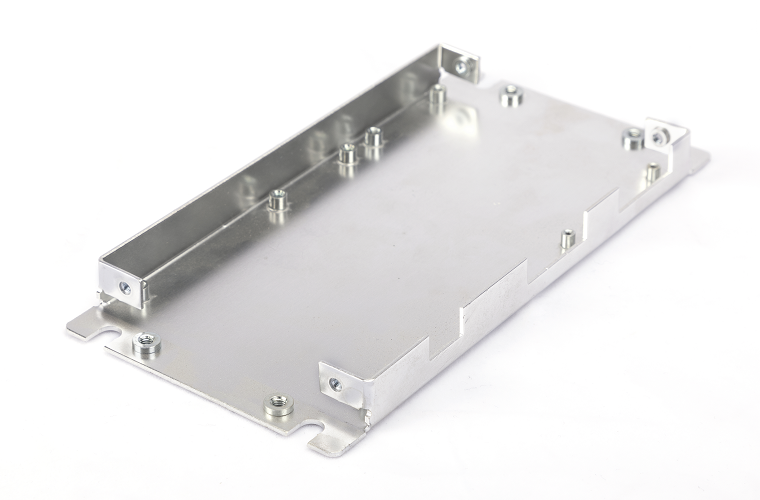

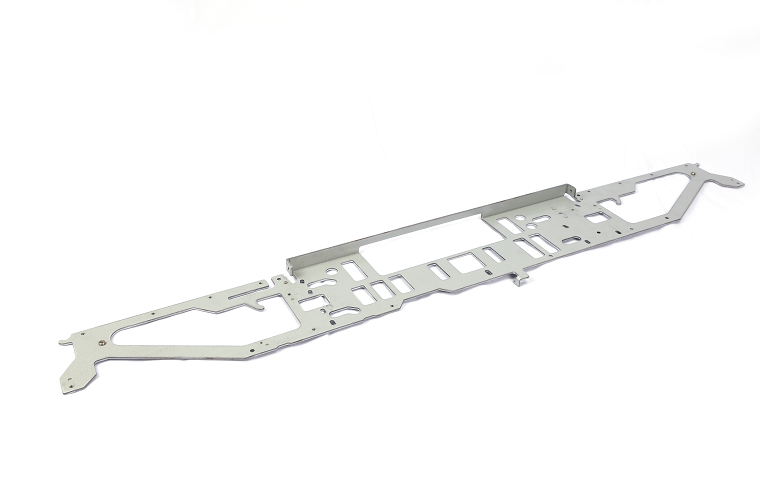

Sheet metal bending part library01

Sheet metal bending part library02

Sheet metal bending part library03

Sheet metal bending part library04

Why choose us to provide metal bending services

At Youxinda, we use the latest and most effective metal bending technology to achieve the best results. Metal bending requires the highest precision to meet industry demands. Youxingda is a certified company with the right tools, expertise and experience to provide precise prototypes and production parts.

Guaranteed high quality

We have a manufacturing plant certified by ISO 9001:2015, and can provide materials and full-size inspection reports according to your requirements. You can always rest assured that the parts you get from Youxingda will exceed your expectations.

Strong manufacturing capabilities

Our domestic factory in China provides complete project solutions for small and high volume production through flexible materials, surface finish options and unlimited manufacturing capabilities.

Sheet metal engineering support

We offer 24/7 online engineering customer support for your custom engineering and manufacturing problems. This includes case-by-case recommendations to help you reduce costs early in the design phase.