Organizing services

Get quick quotes within 12 hours

ISO 9001:2015 certification

24/7 Engineering Support

Our portfolio of surface treatment products

Our parts finishing service is excellent because our team is an expert in plastic, composite and metal surface finishing. In addition, we have state-of-the-art machines and infrastructure to turn your ideas into reality.

As a machining tool

Spray bead

Anodic oxidation

Our Surface Treatment Specifications

Part marking is a cost-effective way to add logos or custom letters to your design, and is usually used to mark custom parts during full production.

Name

Product Description

Materials

Color

Texture

Price

Link

Processing state

The standard surface treatment of our parts, the "after-processing" surface treatment, has a surface roughness of 3.2 μm(126 μin), which can remove sharp edges and cleanly remove burrs from parts.

All Materials

Not applicable

Stain

$

Sand blasting

Grit blasting is a process in which a stream of strongly propelled (usually using high pressure) jetted media impinges on a surface to remove unwanted coatings and surface impurities.

Aluminum, steel, stainless steel, brass, copper

Not applicable

Matte

$

anodic oxidation

Our anodization process keeps our parts resistant to corrosion and wear for a long time. It is also an ideal spray paint and primer surface treatment, and it looks great.

Aluminum material

Transparent, black, gray, red, blue, gold

Smooth, matte finish

$$

Electroplating

The electroplated coating protects the surface of the part and prevents rust and other defects from causing decay by reducing metal cations by applying an electric current.

Aluminum, steel, stainless steel

Gold, silver, nickel, copper, brass

smooth gloss

$ $ $

Polishing

Range from Ra 0.8 ~ Ra0.1, the polishing process uses abrasive materials to rub the surface of the parts to make the gloss less shiny, it depends on your requirements.

All Materials

Not applicable

smooth gloss

$ $ $ $

powder coating

Using corona discharge, we make the powder coating adsorb to the part to form a more wear-resistant layer, with a typical thickness range of 50 μm to 150 μm.

All metal materials

Custom Edition

Smooth

$ $ $

Polishing

Brushing is a surface treatment process in which an abrasive belt is used to draw marks on the surface of a material, usually for aesthetic purposes.

ABS, aluminum, brass, stainless steel, steel

Not applicable

Satin

$$

Paint

Painting involves applying a layer of paint to the surface of the part. The color can be matched to the Pantone color number chosen by the customer, while the surface treatment ranges from matte to glossy to metallic.

Aluminum, stainless steel, steel

Custom Edition

Glossy, Semi-Glossy, Flat, Metallic, Texture

$ $ $

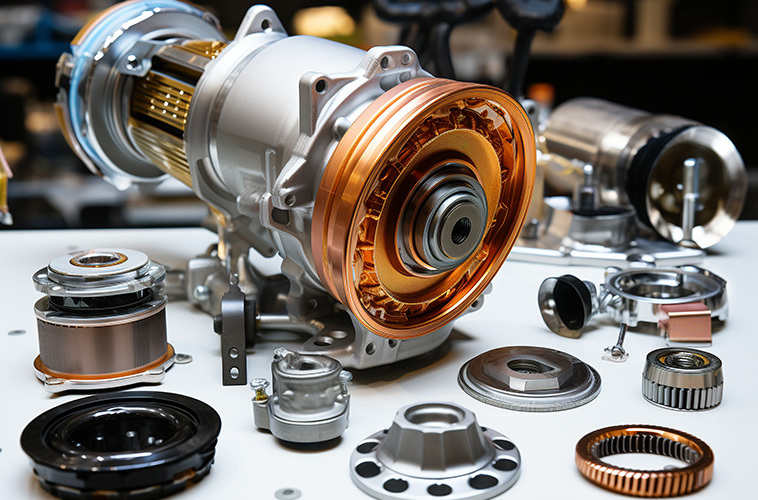

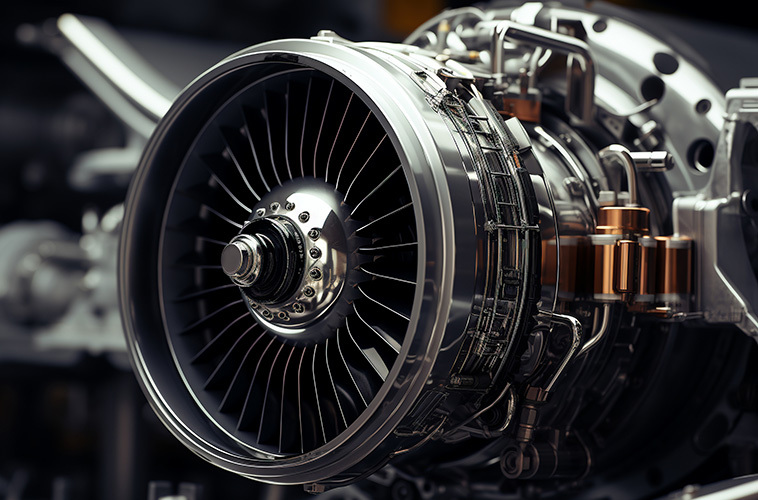

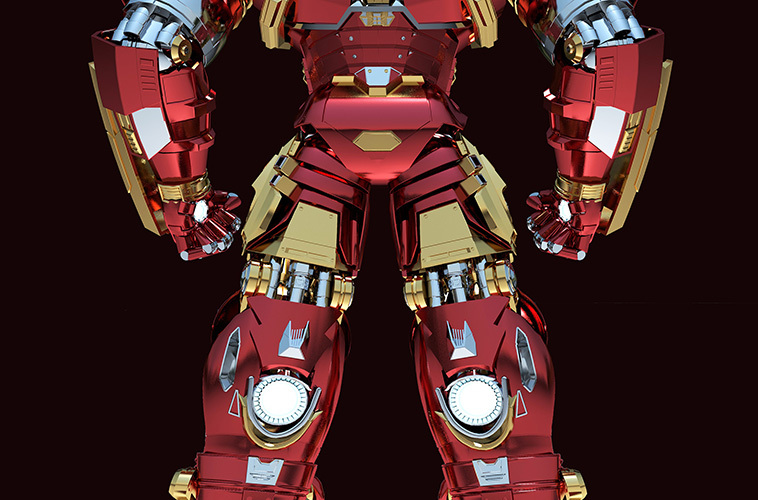

Parts Gallery with Decorative Surface Treatment

Feel the quality-centered custom parts we manufacture using precision surface finishing technology.

Handle various industrial applications

We have been developing high-volume rapid prototyping and low-volume production orders for customers in multiple industries, including automotive, aerospace, consumer goods, medical equipment, robotics, and more.