General issues

Can you provide a monthly billing period?

Unless otherwise agreed, we expect all new customers to make a prepayment before the order is initiated. After a period of cooperation between both parties, evaluate whether to implement the monthly settlement period based on the actual transaction situation of the order.

Unless otherwise specified, all mold orders require a 50% advance payment, and the remaining 50% payment will be made after T1 sample approval. Thank you for your support and understanding!

How long does it usually take to get the parts?

The production cycle depends on the size, quantity, and processing requirements of the parts. In general, orders for prototype models can be completed within 3-9 days, while quick tooling and injection usually take 2-5 weeks.

What are the trade terms of Youxingda?

Normally, for overseas customers, we can comply with international trade terms EXW or DAP and deliver to them via air express delivery such as DHL, FedEx, or UPS. In China, we provide customers with free door-to-door delivery services through express logistics such as SF Express.

Is there a minimum order quantity?

Youxingda does not have a minimum order quantity requirement, and our services can meet your production needs of different quantities, from single piece prototype verification to small batch customized parts production and processing.

How to ensure that customer designs are strictly confidential?

Our factory always implements strict measures to keep customer information confidential, and the development of Youxingda over the years is precisely due to the good reputation it has gained through cooperation with numerous customers. If necessary, we will sign a confidentiality agreement with you.

What format of data file do you need for quotation?

All machining processes are based on complete 3D data. Youxingda requires you to provide 3D data files in STEP, IGES, X-T or STL formats for machining analysis and price evaluation. If there are dimensional tolerance requirements, please provide a 2D file in DWG or PDF format.

Who will interface with my project?

From project initiation to final delivery of parts, we assign a dedicated project manager for each project to provide one-on-one coordination, ensuring thoughtful pre-sales and after-sales service for customers throughout the entire process.

How do I obtain a project quotation?

Youxingda provides you with real-time prices and delivery times for customized parts, and you can obtain quotes through the following two channels:

1. Click on the "Get Quotation" page of the website, submit a form to upload your CAD data and project information.

2. Send your CAD data and project requirements directly to our email xsb@yxd-tech.com .

After receiving your inquiry information, we will contact you within 12 hours and reply with a quotation and DFM manufacturing analysis.

Manufacturing issues

How long will Youxingda keep fast molds for customers?

Youxingda will reserve your mold for 2 years for future use

How fast can I get the parts using a quick mold?

Normally, parts can be delivered within 2-5 weeks using quick molds, but for parts with complex structures or special functional requirements, it takes longer.

How much cost can fast molds save?

For small batch injection molding, using fast molds is very competitive, usually costing 30% -70% of standard steel molds/automatic molds.

What is the lifespan of rapid injection molds?

Rapid injection molds are mainly used to meet the injection production needs of hundreds to thousands of parts. Depending on the selected mold material (aluminum or soft steel) and part structure, the lifespan of rapid molds usually ranges from thousands of times, making them very suitable for the production of small batches of plastic parts.

Can vacuum molded parts be used as final products?

Although vacuum injection molded parts are often used for prototype production, customers often use them as a transitional tool to push products to the market as an alternative process before mass production molds are put into production. For very special products, such as medical equipment, this process is often directly used in production due to its lower mold cost and advantages in fast delivery time. Due to the ability to achieve mass production level appearance quality and the polyurethane material meeting functional requirements, vacuum injection molded parts are suitable for final product use.

What is the accuracy of vacuum injection molded parts?

The standard accuracy that can be achieved by general vacuum injection molding is ± 0.15mm/100mm, and the highest local accuracy can reach ± 0.05mm.

How large parts can vacuum injection molding be used to make?

The maximum mold size that the vacuum mold equipment can accommodate is 2.0M * 1.2M * 1.0M

What material is used in vacuum replication?

Polyurethane resin material, with properties similar to production grade engineering plastics such as ABS, PMMA, PC, PP, PA, etc., is used to make soft rubber or hard plastics from transparent, semi transparent to colored, and even resistant to impact, high temperature (120 ℃), or fire (UL94-V0).

What is the lifespan of silicone molds?

Normally, a silicone mold can pour 12-15 products, and the mold has a shelf life of 2 months.

What is the maximum size of parts that can be machined as a whole by CNC?

Maximum machining size: 1200 x 800 x 600 mm (may be disassembled for machining based on the structural characteristics of the parts)

quality problem

Do you provide OQC reports? Such as material certificates and FAQs?

We can provide OQC reports based on specific customer requirements. If the customer requires it, we can also provide additional material reports, inspection reports, conformity certificates, etc. These information require customers to confirm clearly before placing an order, otherwise it will be difficult to provide temporary information such as material reports.

Can Youxingda provide a 3-coordinate detection report?

We have professional personnel and testing equipment for full-size inspection, and provide CMM reports or 3D scanning reports according to customer needs to ensure that the quality of your parts is within the expected range.

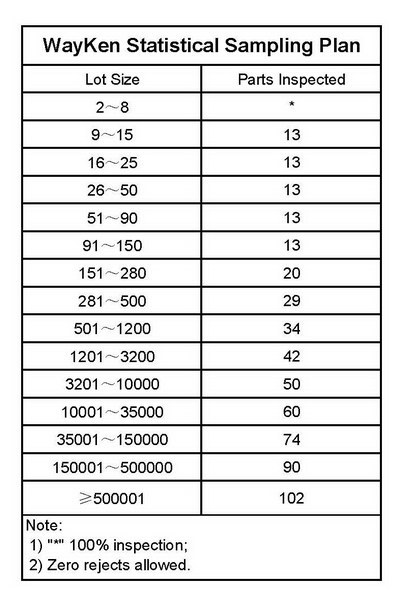

What is your sampling plan?

Our standard sampling plan is based on MIL-STD-105E, a zero defect sampling plan, as shown in the table.

How does Youxingda ensure the quality of parts?

From the beginning of communication, Youxingda proactively understands the quality points that customers are concerned about, and provides cost-effective and rational suggestions in terms of design, materials, production processes, and manufacturability.

Once your order is confirmed, we will conduct a comprehensive Manufacturing Feasibility Analysis (DFM) review to raise any issues we believe may affect the quality of your components.

We will share with you in real-time the order manufacturing process and address any quality issues that may be encountered during the production process. All incoming materials will meet your design specifications, and a comprehensive inspection report can be provided for confirmation before shipment.

Have you passed the quality system certification?

You Xingda has passed the ISO9001:2015 quality system certification. You can download our certificate here.