On demand manufacturing

Get real-time quotes through free DFM feedback

ISO 9001:2015 certification

Powerful engineering and technical support

On demand, on time for you to manufacture

Youxenda lets you meet all your on-demand manufacturing needs. Based on our years of experience and expertise, we will efficiently execute all your on-demand production related projects. Thanks to the unlimited supply chain network of workshops suitable for different manufacturing technologies, you can rest assured that you will deliver the best products at the fastest speed at amazing wholesale prices. In addition, our experienced engineers and experts will provide the best solutions and design modification suggestions to ensure you have the best final product.

CNC machining

High speed and automatic cutting can accurately form different shapes to reflect your design of metal or plastic materials for small batch CNC machining.

Why choose us for on-demand production

We provide the best on-demand manufacturing service for all kinds of production parts. Ensure that our team of experts provide the highest quality and high value advice and professional advice in a timely manner.

Consistent high quality

We use high-quality input materials and maintain a high level of process stability to ensure repeatability. We strive for continuous improvement to improve our ability to manufacture, process and deliver goods.

Strong manufacturing capabilities

To meet your custom production needs, we offer and support a wide range of manufacturing capabilities. For low-volume CNC machining, prototyping, 3D printing and other services, our goal is to bring your prototypes or parts to life in the best possible way.

Fast delivery time

We have a state-of-the-art in-house production supply chain and the strength of our people to help us meet and exceed your expectations for delivery times and quantities. We make sure all our deliveries are within the schedule.

Establish a supply chain system

Our leading suppliers help us receive materials for continuous production while ensuring that the cost of each product is affordable.

Powerful engineering and technical support

Our team of experienced experts is ready to provide professional advice and advice on your orders, improvements and preferences.

Our on-demand manufacturing capabilities

Our CNC turning processes are compatible with a wide range of materials, including mechanical grade metals and plastics. Depending on your application, we can create accurate rapid prototypes and small batch production using a variety of high-quality materials. Check out some common materials for CNC turning projects.

nc machining

nc machining

CNC machining is used to control a wide range of complex machinery. It is a computerized manufacturing process that uses pre-programmed software and code to control the movement of production equipment.

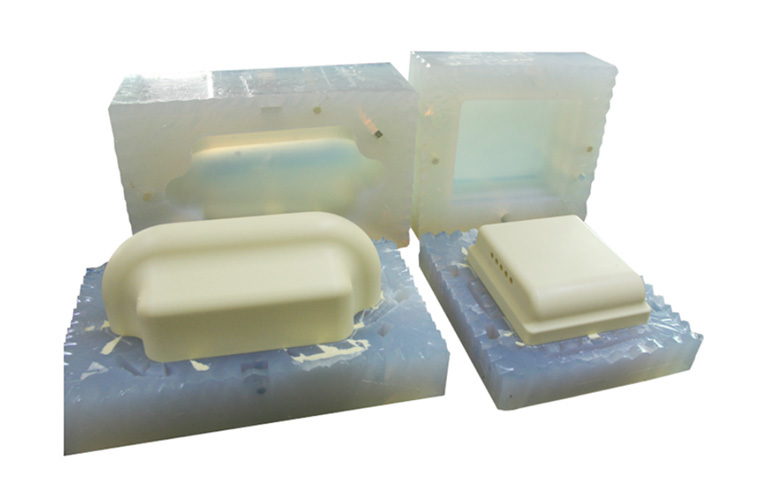

Mold and injection molding

Mold and injection molding

Copper has excellent thermal conductivity, electrical conductivity and plasticity. It also has high ductility, corrosion resistance and is easy to weld.

Price: $

Delivery time: <10 days

Chamber wall thickness: 0.75mm

Tolerance: ± 0.125mm (± 0.005 inches)

Maximum part size: 200 x 80 x 100 cm

sheet metal processing

sheet metal processing

Sheet metal manufacturing is the process of converting flat steel or aluminum into metal structures or products through cutting, stamping, folding and assembly.

vacuum casting

vacuum casting

Vacuum casting is a manufacturing process in which material enters a silicone mold by vacuum to produce complex production parts.

Die Casting

Die Casting

Die casting is a process of manufacturing parts. Various parts are made by pouring or pressing molten metal into steel molds.

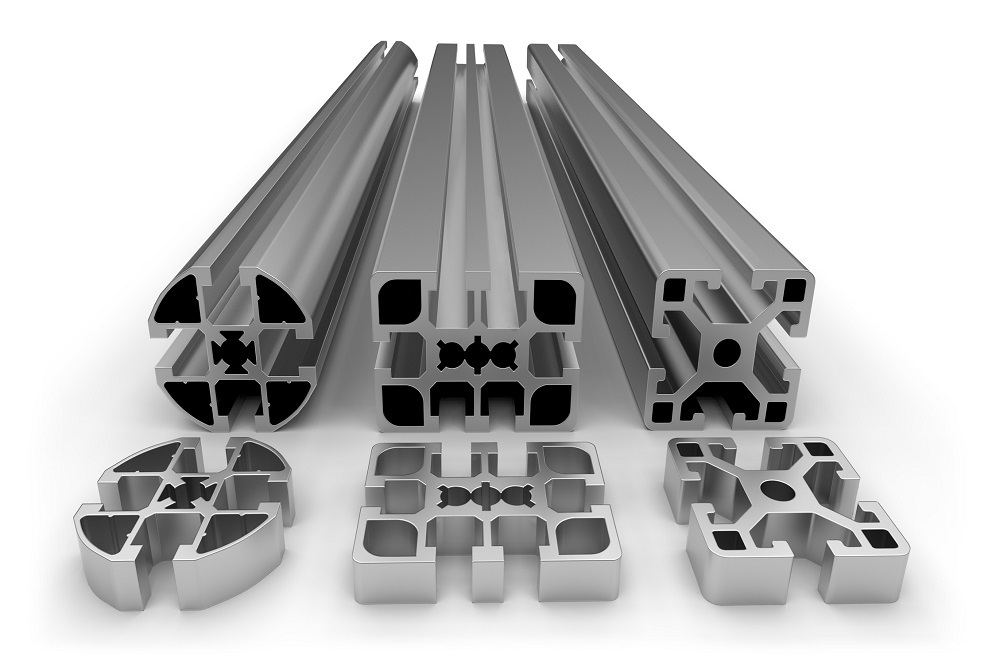

Extrusion processing

Extrusion processing

Extrusion facilitates the manufacture of complex parts through a plastic deformation process. The material is forced to flow through a die or orifice to obtain the desired shape.

3D printing

3D printing

Extrusion facilitates the manufacture of complex parts through a plastic deformation process. The material is forced to flow through a die or orifice to obtain the desired shape.

First-piece inspection

Upon request, we can also provide first piece inspection service for customized production orders with a price of more than $5000 or 50 pieces.

01

02

03

04

Fast and direct

Provide first article inspection

We provide first article inspection services for mass production.

Drafting contracts

We review projects and contact customers for details.

Production samples

We produce sample parts and deliver to you according to FAI agreement.

Full production

Full production starts and finishes production within the delivery time.

Completely

Request Check

You request a first article inspection of an item that meets our FAI requirements.

Sign the contract

You sign the FAI agreement we provide and agree to our terms and conditions.

Receive samples

You receive and inspect the parts, inform us that full production may begin.

Receiving Products

You will receive the prototype or production part within the stipulated delivery time.

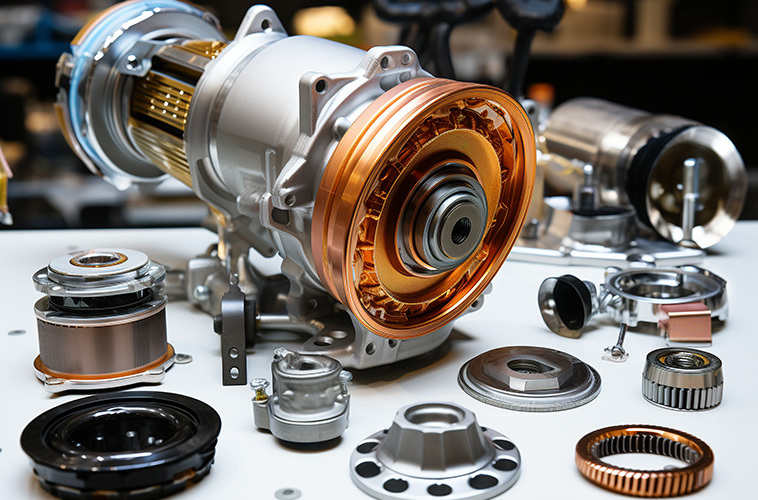

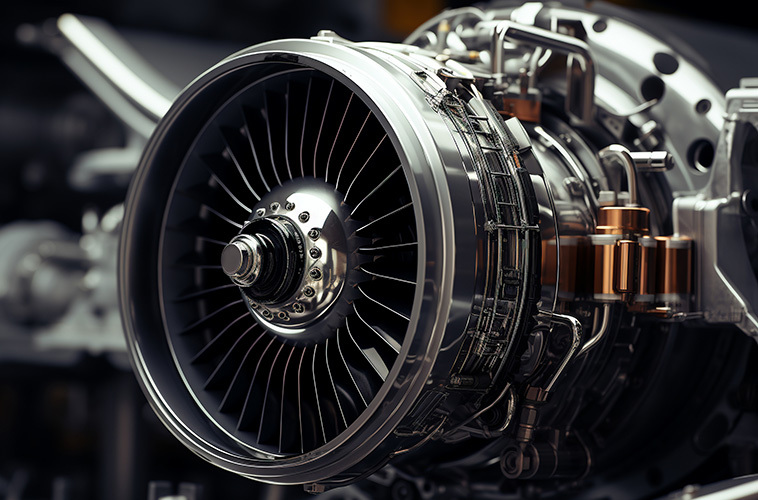

Production-on-demand parts gallery

Take a look at our previously developed production parts and get inspired by your custom manufacturing.

On demand production parts gallery01

On demand production parts gallery02

On demand production parts gallery03

On demand production parts gallery04

Cooperation with almost all industries

Youxenda's on-demand production parts play a vital role in various industries, making us the preferred manufacturer of choice