Customized online sheet metal manufacturing services

12 hour free quotation

The fastest delivery time is 3 days

ISO 9001:2015 certification

Our custom sheet metal fabrication services

Choose Youxingda online sheet metal manufacturing services to produce custom sheet metal parts through complex small batch prototypes and extensive high-volume production. You can choose from a variety of materials and manufacturing processes. Our domestic sheet metal manufacturers and a team of knowledgeable engineers ensure that each part is manufactured to precise specifications and quality standards.

laser cutting

Laser cutting is a technology that guides high-power laser cutting of metal sheets, providing precise and fast processing, and creating complex designs with smooth surfaces and strict tolerances.

Plasma cutting

Plasma cutting is a process that utilizes thermal plasma to accelerate jet cutting of conductive materials. It is an ideal choice for thick materials, providing high speed, low cost, and high efficiency for large-scale industrial metal manufacturing.

Bend

Bending is a multifunctional sheet metal manufacturing process that can form V-shaped, U-shaped, and channel shapes in materials, providing high precision and repeatability at the lowest setup cost. Very suitable for complex geometric shapes.

Advantages of laser cutting

Laser cutting brings many benefits to many industries, including precision, speed, repeatability and flexibility. Yxd's laser cutting services help meet the functional and aesthetic requirements of the industry.

High-precision cutting: The beam involved in laser cutting ensures high-precision melting and evaporation of the material, ensuring accuracy as low as 0.003mm.

Maximum plate utilization: Laser cutting technology maximizes the number of available metal plates, with almost no wasted space, ensuring that only accurate quantities of material are provided.

High cutting versatility: Through advanced laser cutting operations, you can obtain customized laser-cut parts with simple cutting, marking, engraving and complex details.

Low power use: The sheet metal laser cutting machine can effectively cut the material block without consuming too much energy, usually only using 10kW of energy.

Almost no damage: The heat generated by the laser cutting process has very little effect on the parts and has no effect on the tolerances of the laser cutting parts.

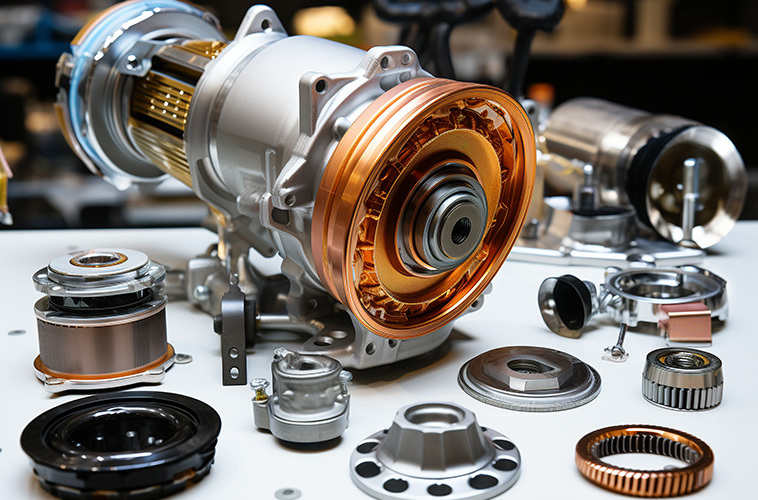

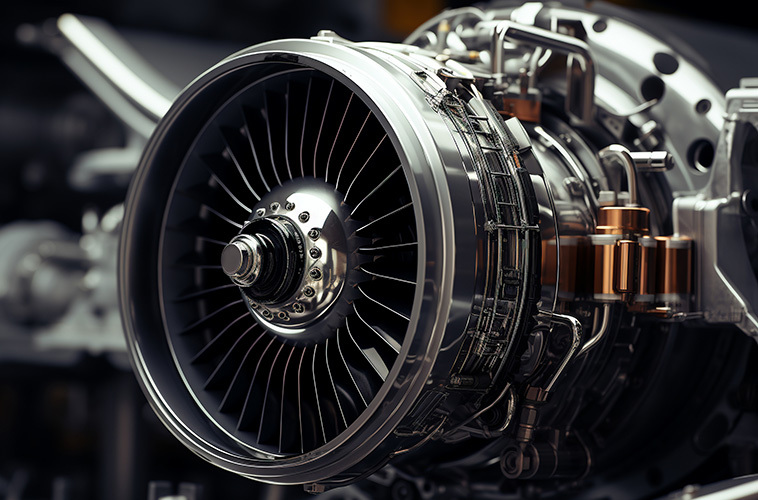

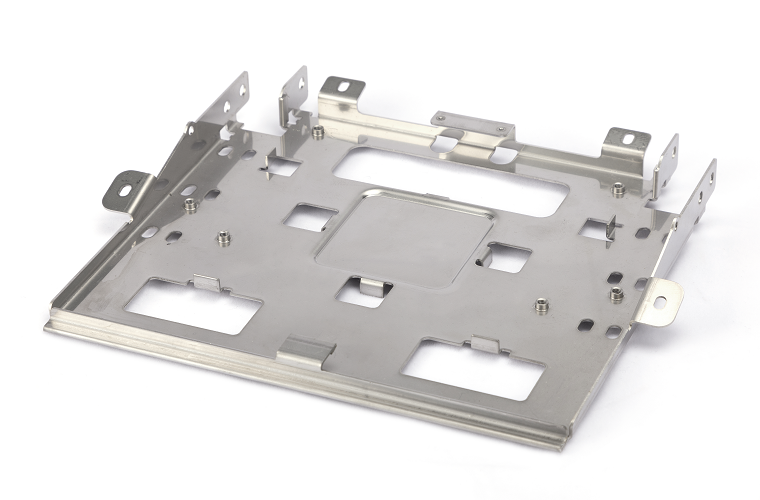

Sheet metal parts manufactured by Youxingda

View customized flat and molded sheet metal prototypes and production parts, from durable brackets to complex panels, all of which have been precision produced to meet different industry needs.

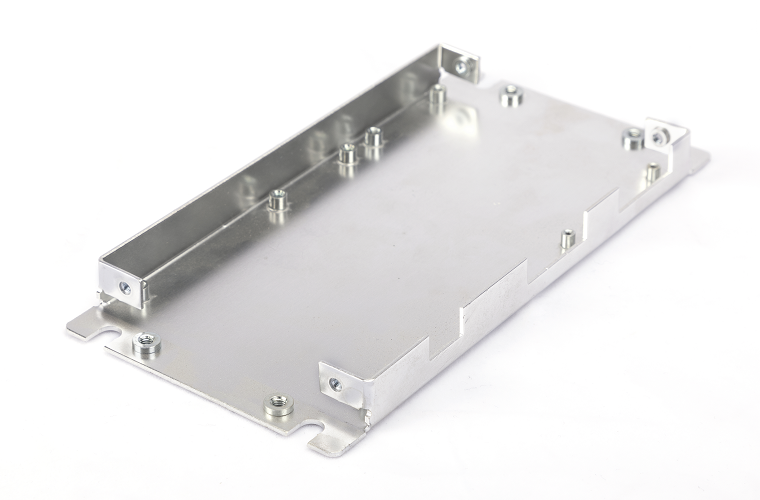

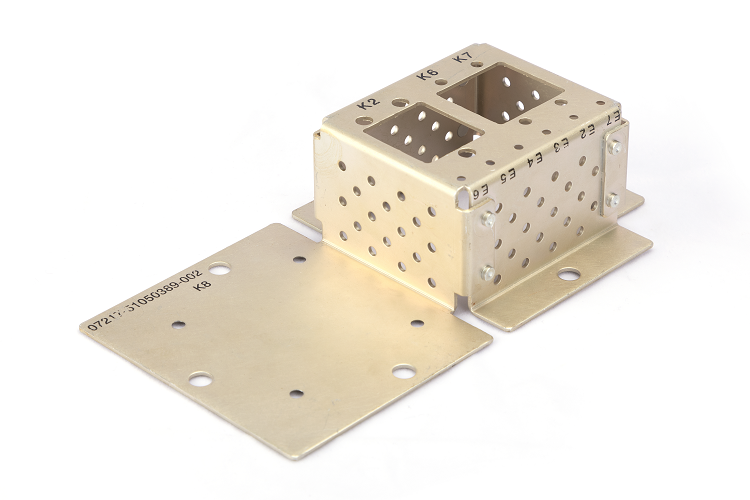

Manufactured sheet metal parts 01

Manufactured sheet metal parts 02

Manufactured sheet metal parts 03

Manufactured sheet metal parts 04

Why choose us for laser cutting

With cutting-edge laser cutting technology and innovative technical expertise, Youxenda is committed to providing the best custom laser cutting services through prototyping and mass production runs. We are a reliable manufacturing company with the appropriate certification and experience to provide cost-effective on-demand laser cutting solutions.

On demand production

Use Youxenda to quickly convert CAD designs into final CNC milling prototypes. Test and refine your concepts, reduce costly milling errors, and accelerate time to market.

Bridge fabrication

Seamless transition from prototype production to CNC milling production. Ensure a smooth transition phase, reduce expansion risk and maintain consistent quality with Youxingda's Bridge Production.

On demand production

Meet market demand with on-demand precision CNC milling. Youxingda ensures that you complete tasks on time, effectively manage inventory and accurately produce high-quality components when needed.

Sheet metal processing materials

The sheet metal materials we choose include aluminum, brass, stainless steel and copper, each of which can enhance the durability and aesthetics of metal parts.

Aluminum material

Aluminum material

Aluminum is light and strong, providing enhanced durability without adding weight. Its excellent ductility enables precise forming, making it ideal for complex designs.

AL5052

AL5083

AL6061

AL6063

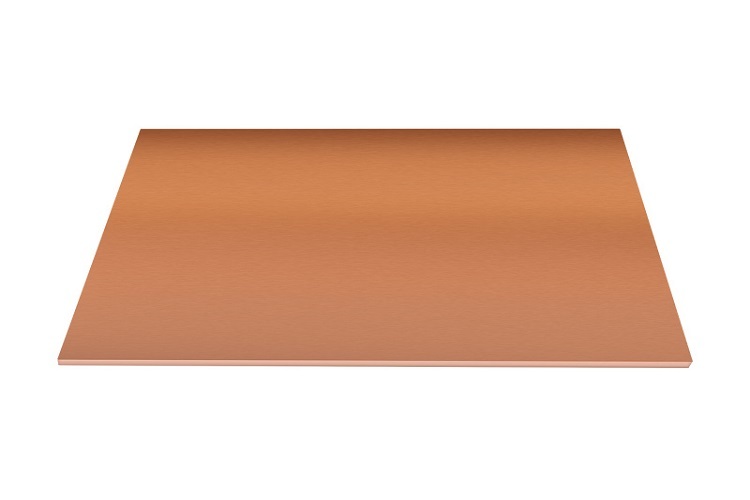

Copper

Copper

The advantages of copper are clear: unparalleled electrical conductivity, thermal efficiency and natural corrosion resistance ensure manufacturing life and performance.

CU1020

CU1100

CU2100

CU2200

CU2300

CU2400

CU2600

Brass

Brass

The choice of brass ensures precise processing, unique appearance and efficient thermal conductivity, providing advantages for practical and decorative applications.

C27400

C28000

Steel

Steel

Steel is rugged, versatile and recyclable, making it an excellent material choice to ensure long-lasting performance and environmental sustainability.

Cold Rolled Steel Sheet (SPCC)

Hot Rolled Steel Sheet (SPHC)

Electrolytic Plate (SECC)

Galvanized Sheet (SGCC)

Stainless Steel

Stainless Steel

Stainless steel is known for its durability and stain resistance, ensuring longevity and maintaining its appearance even in harsh environments.

301

303

304

316

420

430

Surface treatment of sheet metal processing

Choose from our various sheet metal finishes to enhance corrosion resistance, durability and visual appeal. For finishes not listed on our quote page, simply select "Other" and specify your requirements for a customized solution.

Name

Materials

Color

Texture

Thickness

Link

anodic oxidation

Aluminum material

Transparent, black, gray, red, blue, gold.

Smooth, matte finish.

Thin layer: 5-20 µm

Hard anodic oxide film: 60-200 µm

Sand blasting

Aluminum, Brass, Stainless Steel, Steel

does not contain

does not contain

0.3mm-6mm

powder coating

Aluminum, Brass, Stainless Steel, Steel

Black, any RAL code or Pantone number

Gloss or semi-gloss

5052 aluminum 0.063 "-0.500 ″

6061 aluminum 0.063 "-0.500 ″

7075 aluminum 0.125 "-0.250 ″

Mild steel 0.048 "-0.500 ″

4130 chrome molybdenum steel 0.050 ″-0.250 ″

Stainless steel 0.048 "-0.500 ″

Electroplating

Aluminum, Brass, Stainless Steel, Steel

Variable

smooth gloss

30-500 micro inches

Youxingda sheet metal process

When you order custom metal manufacturing parts, look at the specific benefits of each sheet metal technology and find the perfect match.

Process

Technology

Platform accuracy

Application areas

Material thickness (MT)

Delivery time

slitting

Laser cutting, plasma cutting

/- 0.1mm

Stock material cutting

External shape cutting

secondary cutting

Cutting line

Cutting irregular holes

6mm (XNUMX/XNUMX inches) or less

1-2 days

Bending

Bending

Single bend: /- 0.1mm Double bend: /- 0.2mm More than two bends: /- 0.3mm

Forming, pressing line, stamping character, riveting electrostatic guide, pressing ground symbol, punching, flattening, pressing triangle rib, etc.

The minimum bending radius shall be at least equal to the sheet thickness.

1-2 days

Welding

TIG welding, MIG welding, MAG welding, CO2 welding

/- 0.2mm

For aircraft fuselage and engine components. For body, exhaust system and chassis. Create generation and distribution system components.

Down to 0.6mm

1-2 days

General tolerances for sheet metal fabrication

Our sheet metal shop follows ISO 13485 tolerances to provide consistent quality. For tolerances that exceed these standards, please specify your requirements on the design schematic or contact our engineers. By default, sharp edges will be snapped and deburred. For any critical edges that must be kept sharp, please note and indicate in the drawing.

imperial units

Metric units

imperial units

Side to side, single-sided

/- 0.127mm

/- 0.005 inches

Edge to hole, single-sided

/- 0.127mm

/- 0.005 inches

Hole to hole, single-sided

/- 0.127mm

/- 0.005 inches

Bent to edge/hole, single-sided

/- 0.254mm

/- 0.010 inches

edge to feature, multiple surfaces

/- 0.762mm

/- 0.030 inches

Over-molded parts, multi-surface

/- 0.762mm

/- 0.030 inches

Bending angle

/- 1°

By default, sharp edges will be snapped and deburred. For any critical edges that must be kept sharp, please note and indicate in the drawing.

How does Youxingda Online Custom Sheet Metal Processing work?

We connect you with domestic sheet metal suppliers, from the initial prototype to the finished assembly. After finalizing the specifications, our skilled sheet metal manufacturers will convert your CAD design into precise machine code. They skillfully stretch, cut and bend thin metal plates to form the desired shape, thickness and intended use. We adhere to strict quality standards throughout the process, ensuring that welding, riveting and fastening are all brought together to produce a final product that meets your unique requirements.

Our sheet metal manufacturing is suitable for various applications

Through customized sheet metal, Youxingda can support different industry needs

Why choose Youxingda for online sheet metal manufacturing services

Bring your precision CNC machined parts to life with first-class precision machining services. Youxingda has cutting-edge high-precision CNC machining manufacturing capabilities. All prototypes and end-use parts meet strict quality standards and tolerances.

Guaranteed high quality

Work with Youxingda's engineering experts to overcome complex design challenges. Our expertise ensures accurate, innovative solutions that reduce your workload and improve product quality.

Rapid turnover

We take advantage of unlimited capacity and flexible shipping options to guarantee delivery times as fast as 3 days. Accelerate your sheet metal projects to ensure timely delivery and competitive advantage.

Sheet metal engineering support

Work with Youxingda's engineering experts to overcome complex design challenges. Our expertise ensures accurate, innovative solutions that reduce your workload and improve product quality.

Sheet Metal Manufacturing Overview

What is sheet metal processing?

Sheet metal manufacturing is a key process in manufacturing that involves forming thin metal sheets into metal components. This technology is highly valued for its precision and durability, and can produce essential items such as shells, brackets, and chassis. It is an ideal choice for different industries, ensuring the quality and reliability of end use products. Yuxingda Industrial Sheet Metal Services emphasizes its role in advanced engineering solutions, excelling in transforming metals into indispensable high-performance parts.

What are the advantages of sheet metal processing

Sheet metal manufacturing is the perfect process for prototyping and mass production of metal components.

- Advanced technology can achieve high-precision cutting and forming, ensuring consistent quality.

- The metal components are sturdy and durable, suitable for harsh environments.

- The effective utilization of materials and the ability to expand or reduce production scale make it a cost-effective solution.

- Various surface treatment techniques, such as powder coating, provide aesthetic flexibility and additional protection.

What is sheet metal application?

The adaptability of sheet metal has shone brightly in various applications, meeting both large-scale and unique small-scale needs. Common metal parts include:

- Electrical enclosure

- Computer electronic components

- Sturdy chassis

- Accurate bracket

- Durable cabinets