Aluminum extrusion service

Highly customizable configuration files for different applications

Rapid production without affecting quality

Simplify processes to improve cost efficiency

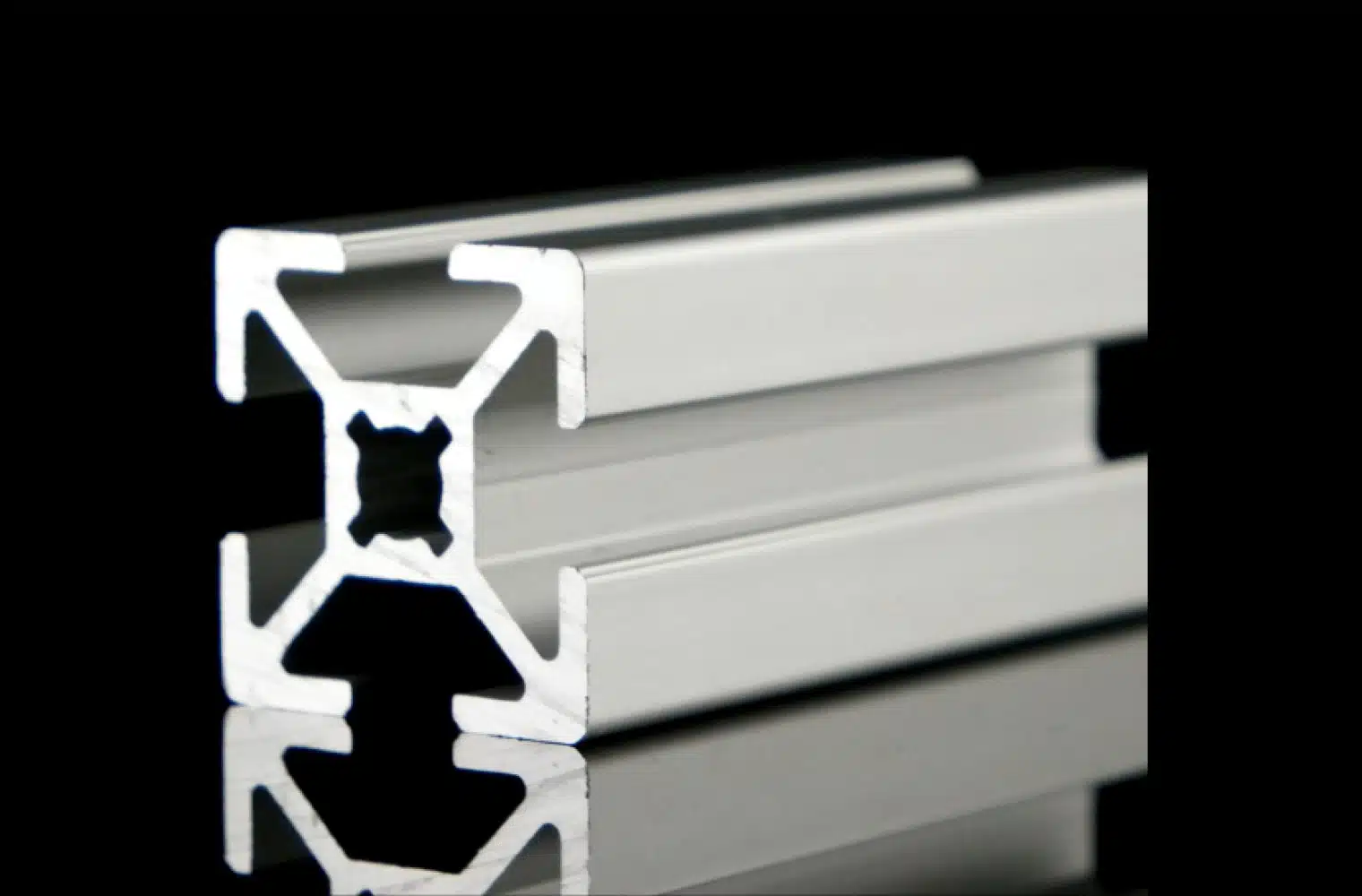

Aluminum extrusion is a multifunctional manufacturing technology that can press aluminum alloy materials into metal extrusion molds with a consistent cross-sectional shape. A large punch press pushes the heated aluminum billet through the die through an extruder or hydraulic press, and then exits through the die hole.

As a leading manufacturer of vacuum casting, Youxenda provides low-cost manufacturing of high-quality plastic parts. This technology eliminates the need for expensive upfront investment. Our vacuum casting services provide a complete solution for creating high-quality prototypes and small-volume production parts.

Why Choose Youxenda for Custom Aluminum Extrusion

In precision manufacturing, wire cutting stands out as a process that provides high precision and complex details. For companies looking for the best wire cutting services, Youxingda is the first choice.

Customization

Our process involves a thorough analysis of the unique specifications of your product. We seamlessly blend extrusion with multiple methods to precisely manufacture custom aluminum profiles.

Fast turnaround time

Youxingda has passed the ISO 9001 certification, using advanced technology to ensure accuracy. Our extruded aluminum parts have precise dimensions, structural durability and consistent performance.

Fast turnaround time

Youxingda reduces cycle time by up to 50%, provides instant quotes and fast delivery. Using advanced technology and extensive expertise, we ensure high-quality aluminum extrusion parts and accelerate turnaround

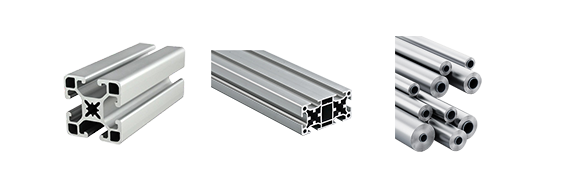

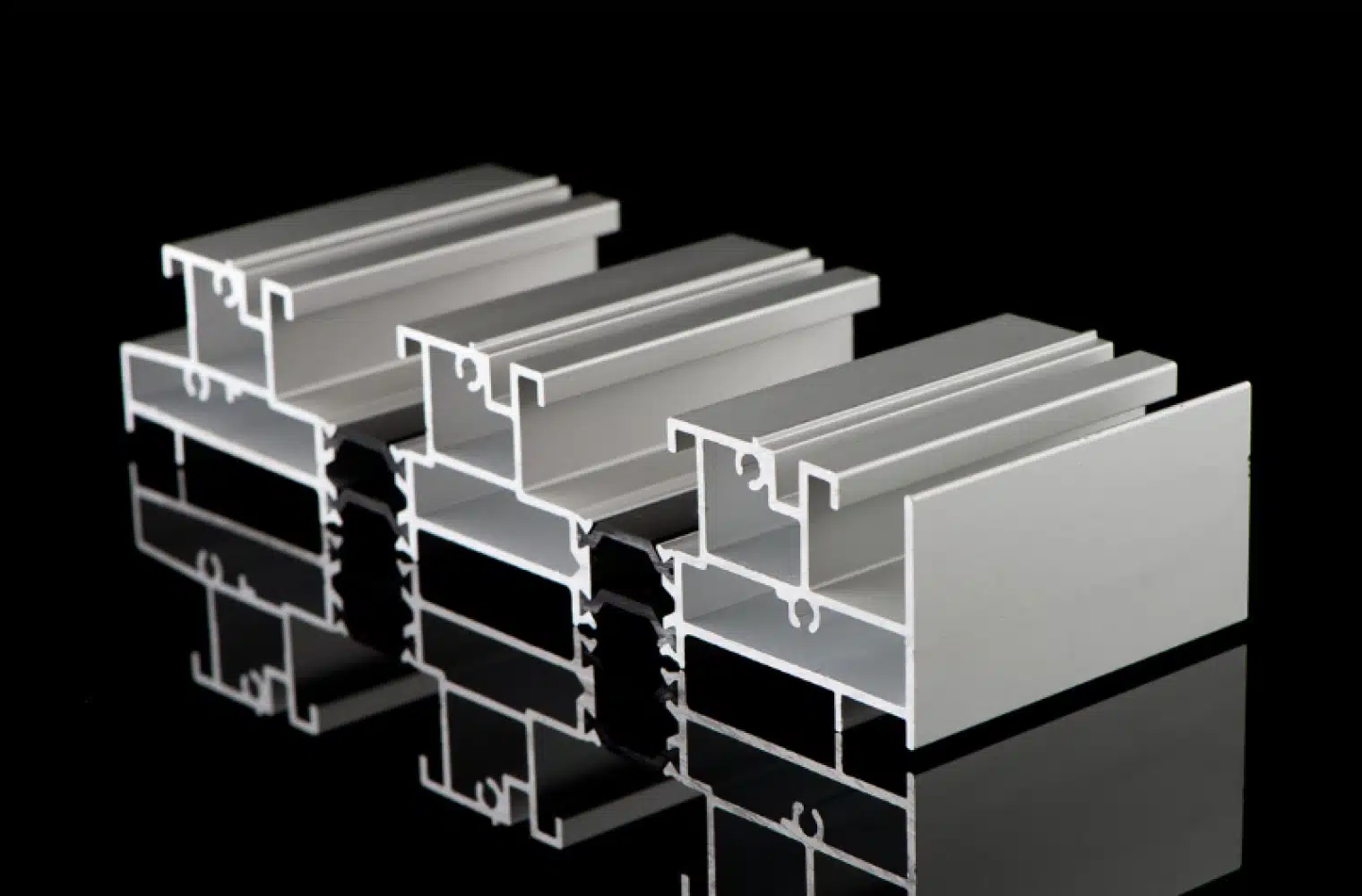

Standard Extrusion Profile

Youxingda will cooperate with you to produce standard extrusion profiles suitable for various projects. Our professional technicians can help you create standard profiles of different sizes and shapes, from round bars and tubes to square bars and tubes and more

T-slot aluminum profile

Aluminum Angle

T-bar, H-bar, Z-bar

I-beam

U channel

Hat Channel

rectangular tube

round pipe and pipe

Standard dimensions for extruded profiles

Item

Dimensions

1

160mm x 160mm

2

20mm x 20mm

3

30mm x 30mm

4

40mm x 40mm

5

45mm x 45mm

6

50mm x 50mm

7

60mm x 60mm

8

80mm x 80mm

9

100mm x 100mm

10

160mm x 160mm

Note: These are common general-purpose profiles used in T-slot aluminum profiles for frames and other applications. For specific industries or applications (such as door and window or structural design), standard dimensions may vary.

Custom Aluminum Extrusion Profile

Youxingda offers precise custom length extrusion profiles, suitable for prototyping and small batch production. We offer flexible designs and serve a wide range of industries with complex contours.

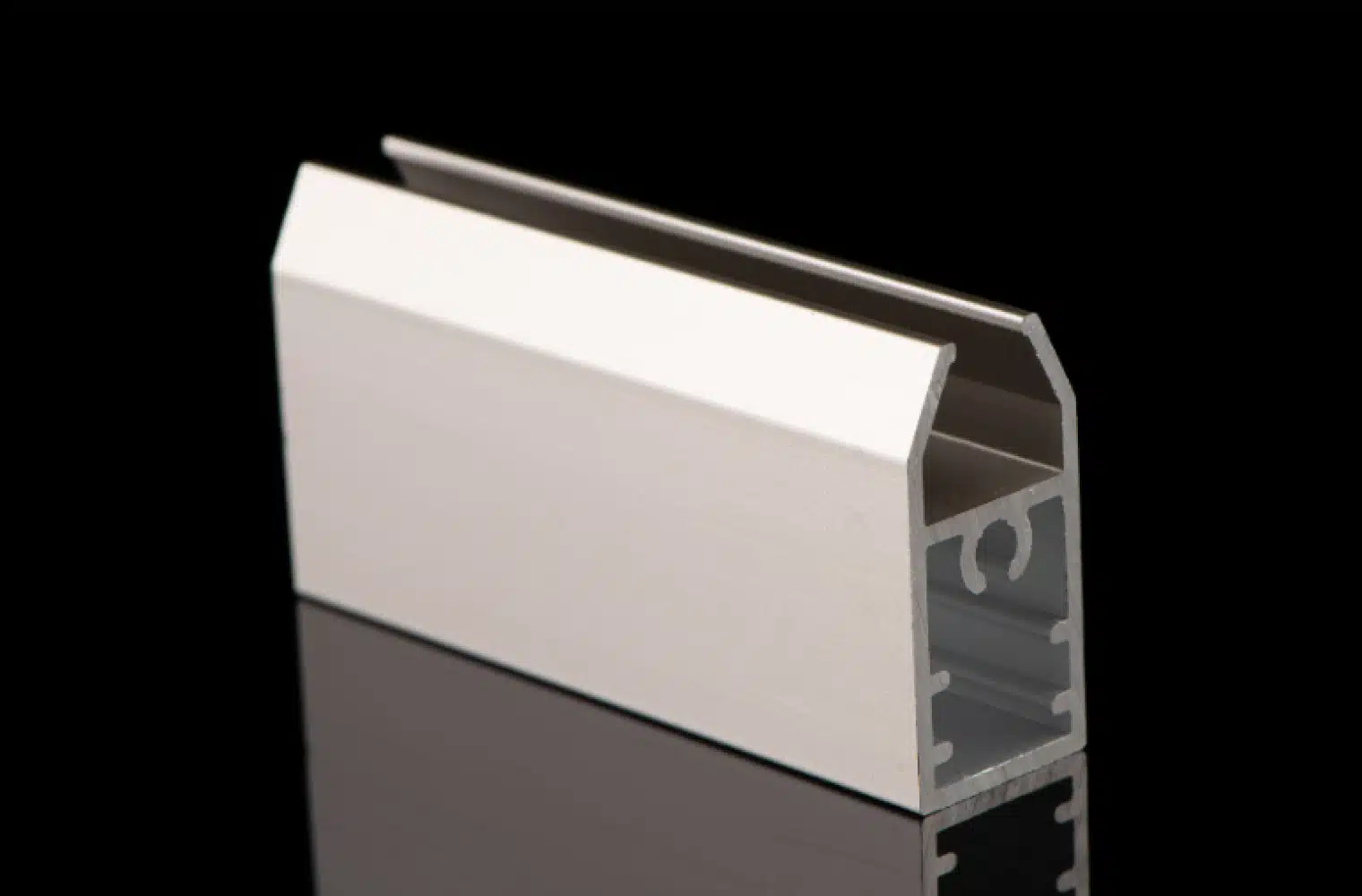

Aluminum groove

We produce customized aluminum grooves, combining advanced extrusion technology with precision engineering.

Extruded aluminum

We convert aluminum into sturdy, customized profiles suitable for different industries, ensuring optimal performance.

Aluminum trim

Our aluminum decorations blend aesthetics with functionality. We make the edges the perfect finishing touch, ensuring elasticity and visual appeal in every application.

Aluminum alloy for extrusion

Youxenda uses different grades of aluminum in different applications, including electronics, consumer goods, aerospace and automotive. These alloys have excellent strength, corrosion resistance, formability, etc.

Alloy 6061

Alloy 6061

6061 aluminum has high weldability, toughness and corrosion resistance, making it ideal for automotive, marine and electronic components.

Alloy 6063

Alloy 6063

6063 alloy can be heat treated, is cost-effective, has enhanced corrosion resistance and strength, and is ideal for radiators, decorations and construction; the grains are finer than 6061, and the finish is also very good.

Alloy 7075

Alloy 7075

7075 are commonly used in aircraft and aerospace applications. The alloy has good fatigue strength and average machinability, but may have poor corrosion resistance.

Alloy 2024

Alloy 2024

It is favored in the aerospace field for its high strength to weight ratio and fatigue resistance. Although the weldability is limited, the 2024 has good workability and becomes stronger by heat treatment.

Alloy 1100

Alloy 1100

1100 is the purest aluminum alloy, known for its excellent corrosion resistance, high thermal conductivity and excellent processability, and is suitable for chemical equipment and kitchenware.

Post-processing of aluminum profiles

slitting

Drilling

Mill

talk about

Grinding

Boring

Pipe

Deburring

Surface treatment of aluminum profiles

Name

Color

Texture

Link

Extrusion state

Aluminum alloy of silver gray or various shades

Matte or mercerized

/

Wet painting

Green, yellow, black, white, gray, silver, brown, green and so on.

Gloss, smooth, matte or metallic

/

chemical membrane

Rainbow effect

Smooth

/

Media Plunge

Green, gray, brown, silver gray

Smooth satin, textured

/

Custom Edition

Any color suitable for project requirements

Smooth, matte, texture, etc

/

Aluminum Extrusion Applications

Our aluminum extrusion capabilities meet the needs of a wide range of applications. We offer high quality aluminum extrusions for various aluminum extrusion companies. These include:

Electronic products radiator

Electronic product shell

LED Lighting Profile

aircraft structural parts

Home Appliances

Auto Parts

BIKE RACK

Window and door frames

Solar panel frame

CONVEYOR STRUCTURE

Wind turbine components

Display racks and retail installations

aluminum extrusion process

We rely on the latest technology and equipment to deliver prototypes and end-use parts faster and more accurately, helping customers reduce product costs and development time. The following is the process we use to manufacture aluminum profiles:

direct extrusion

In this process, a high pressure punch forces the aluminum billet or heated aluminum through a heated walled container. We often use direct extrusion because it has more important profile design and excellent quality finishing capabilities.

indirect extrusion

We use indirect extrusion to provide top aluminum extrusions, where the blank and container move together and the mold is stationary. This method reduces friction, ensures better thermal control, and produces excellent grain structure and mechanical properties.

Hot extrusion, warm extrusion, cold extrusion

We provide hot, warm and cold aluminum extrusion services. Hot extrusion heats the billet to recrystallize, while the cold and hot temperature is kept below this temperature, thereby increasing the strength and hardness of the aluminum.