Rapid Prototyping and On-Demand Production for

Aerospace Industry

Production-grade products

ISO 9001:2015 certiified

24/7 engineering support

Why Choose Us?

Youxingda specializes in reliable aerospace part prototyping and production, ranging from simple to complex projects. We combine manufacturing expertise with advanced technologies and adherence to quality requirements to bring your ideas to life. Regardless of the end use of your aircraft parts, RapidDirect can help you reach your unique goals.

Strong Manufacturing Capabilities

As an ISO 9001 certified manufacturing company, RapidDirect’s production line features advanced technologies to ensure manufacturing accuracy and precision. Every aerospace part comes with the correct dimensional specifications, structural strength, and performance.

Tight Tolerance Aerospace Parts

We can machine aerospace parts with tight tolerances up to +/-0.001 inches. We implement ISO 2768-m standard tolerance for metals and ISO-2768-c for plastics. Our manufacturing capabilities can also accommodate intricate designs for custom part manufacturing.

Fast Cycle Time

With quotes within minutes and parts within days, you can reduce cycle times by up to 50% with Youxingda. A perfect combination of advanced technologies and extensive technical experience helps us deliver superior-quality aerospace parts with faster lead times.

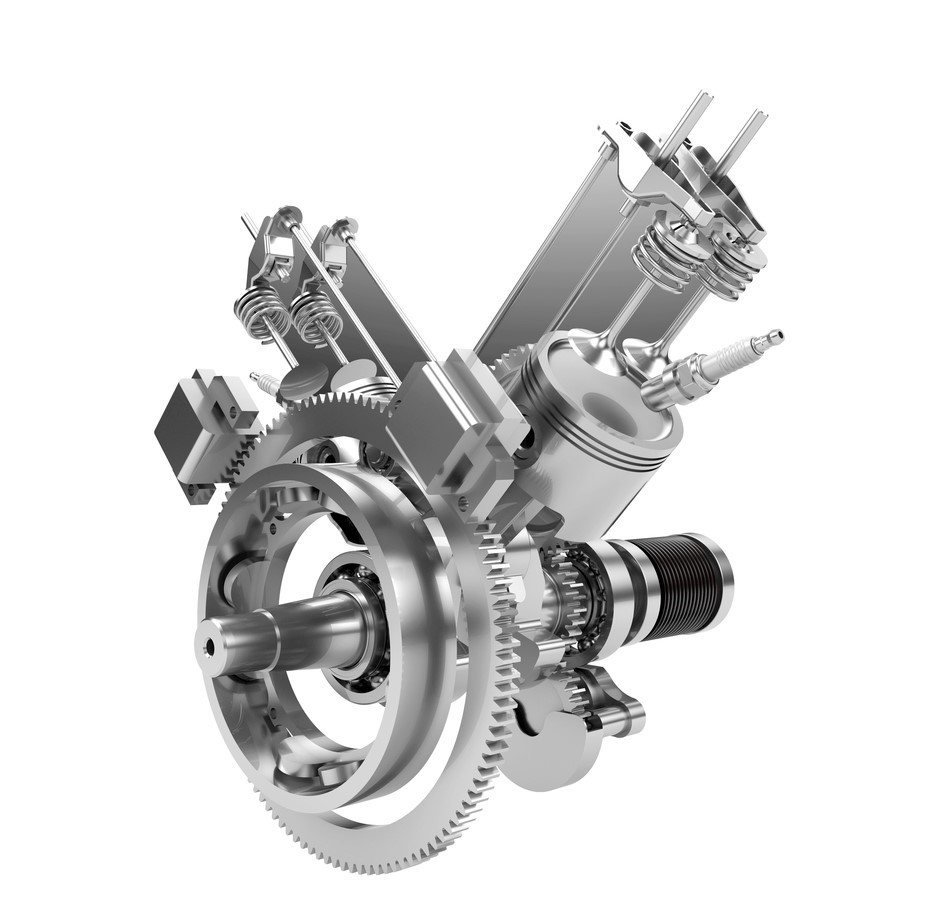

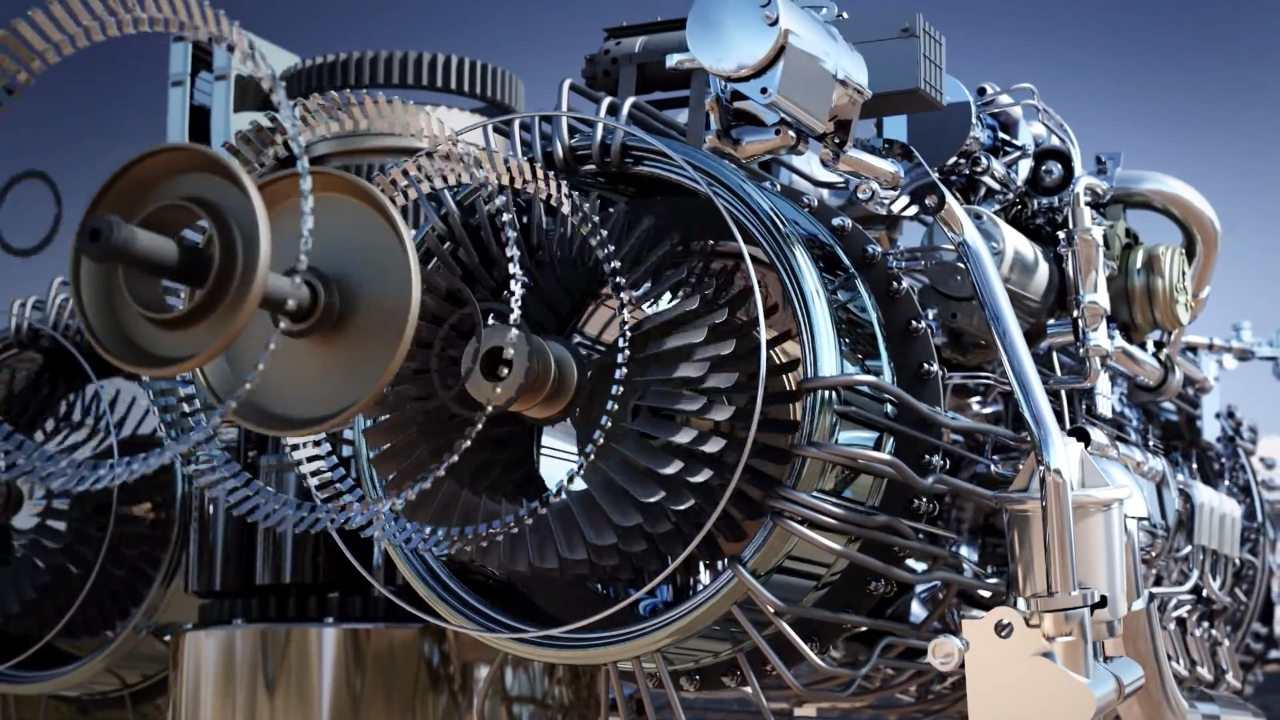

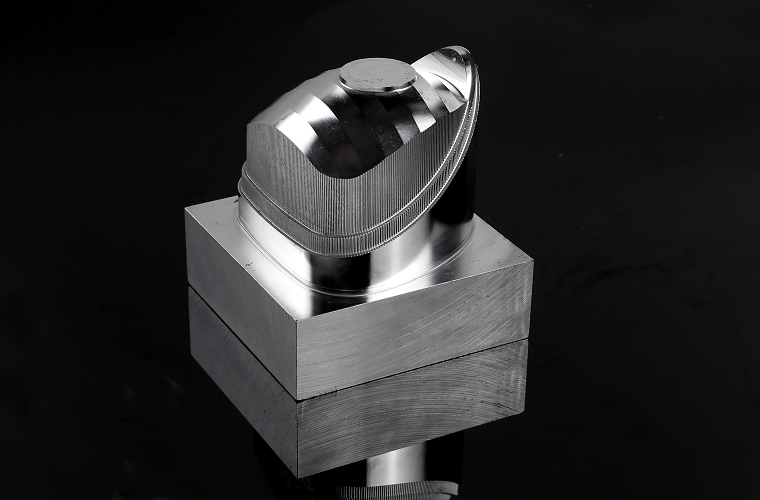

CNC Machined Aerospace Turbo Engine Prototype

Youxingda championed the rapid prototyping of a high-end complex aerospace engine with high tolerance requirements. Despite the strict part assembly demands and complicated turbo blade programming, RapidDirect’s 5-axis CNC machining capabilities created a turbo engine that meets all industry demands.

Prototyping and Production Solutions for Aerospace Industry

Youxingda solutions for new product development in the aerospace industry. Get expertly engineered custom prototypes and production parts with outstanding performance and durability. Our solutions span various production stages to meet your manufacturing goals.

Prototyping

Prototyping

Get high-quality prototypes for early-stage product development. Test your designs, make important material and design iterations, and get prototypes ready for testing.

Prototyping

At this stage, we will help you create prototypes according to your product’s requirements and design files. Depending on your needs, we will use low-cost materials and processes to develop parts similar to the final product. This allows you to examine the specification metrics and functional testing. Our advanced technologies also help us ensure the rapid turnaround of these prototypes.

Rapid Material and Design Iterations

Detailed Prototypes for Complex Geometries

Models Similar to Final Products

Engineering Validation and Testing (EVT)

Engineering Validation and Testing (EVT)

Iterate easily and quickly on precise functional prototypes to ensure all performance requirements are met.

EVT

EVT Our functional prototypes help you identify every design risk and easily mitigate these risks. This may require several iterations to ensure the prototypes meet all functional requirements and performance metrics.

Precision parts manufacturing

Reliable design and engineering support

Optimized material properties for custom design

Design Verification and Testing (DVT)

Design Verification and Testing (DVT)

Effectively verify the function, performance and appearance of parts using a wide range of material and surface treatment options.

DVT

This stage of production helps you analyze the final feel and look of aerospace components. Youxenda has a wide range of mechanical designs, materials and finishes to meet your unique needs. We manufacture parts with end-use functions and provide ideal finishes for consumer and market testing.

High quality parts for consumer and market testing

Performance and appearance verification

Durable and high-quality surface treatment

Production Verification and Testing (PVT)

Production Verification and Testing (PVT)

Get your design ready for full-scale production with production-grade manufacturing capabilities and advanced quality control

PVT

Take control from the DVT stage and get feedback on your design to ensure you meet your production goals. Make final changes to your model to ensure more efficient manufacturing. At this stage, we will work with you to consolidate the manufacturing process and establish the supply chain.

Fast delivery of production quality parts

Manufacturing Process Validation

Small batch production tools

Verify the functionality of production-ready parts

Mass Production

Mass Production

Seamless transition from product testing to mass production of end-use parts. Get the opportunity to adopt precise quality requirements and deliver the final product quickly.

Mass Production

We take charge of your part production with our engineering expertise and advanced manufacturing processes. Our professional technicians ensure that your production output and quality remain high, while reducing costs and shortening delivery times.

High quality custom end-use parts

Tight tolerances for precision machined parts

Secondary operation for better surface requirements

Strict inspection and quality control

Trusted by Fortune 500 companies

aircraft original equipment manufacturer

Space Technology Corporation

Satellite Manufacturers and Operators

Commercial Airlines

Space Launch Operator

Unmanned aerial vehicles and drone delivery systems

Aircraft maintenance and overhaul services

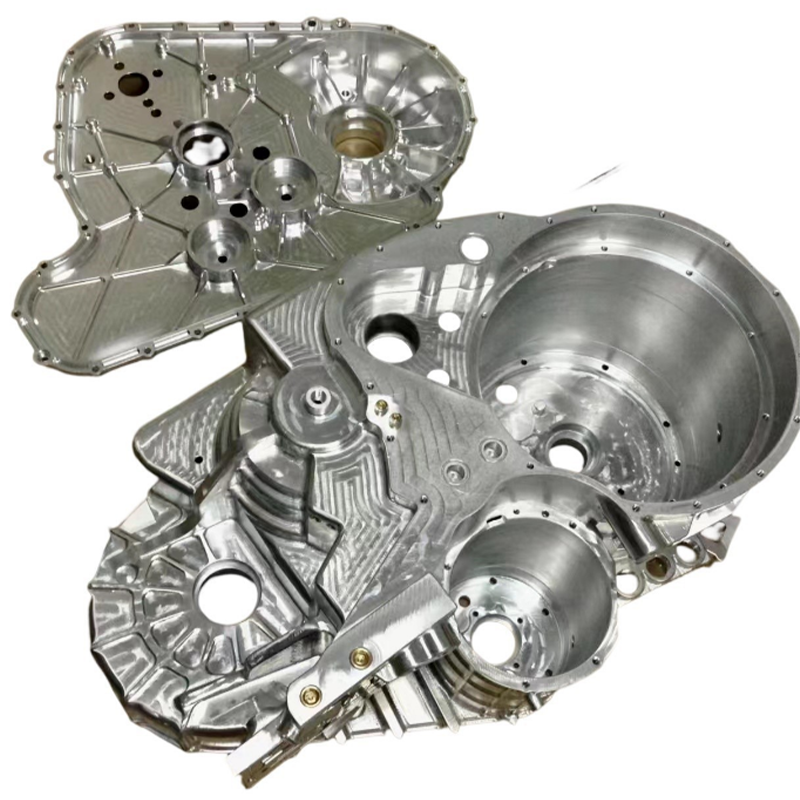

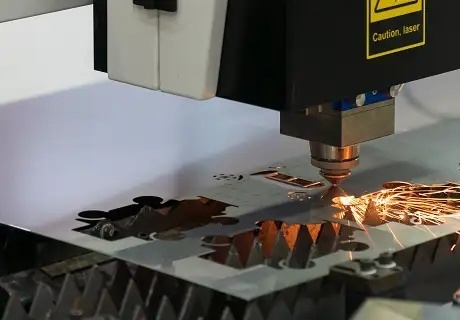

Aerospace Manufacturing Capability

Leverage our professional manufacturing services throughout the production cycle, from prototyping and design validation to functional testing and product release. We provide high quality and accurate flying parts with fast turnaround and low cost. With our quality control process, you can be sure to get parts that meet your unique requirements.

CNC machining

Injection molding

Sheet metal processing

3D printing

Aerospace Component Materials

According to the requirements of your aerospace parts, our processing technology can be compatible with a variety of materials. We have a long list of production grade metals and composites that meet the needs of the aerospace industry. Check out some common materials for aerospace components.

Aluminum material

Aluminum material

Aluminum has an excellent strength-to-weight ratio in this metal. This is a good choice for the high load requirements of aircraft supports and housings. Aluminum also has good ductility, stiffness, corrosion resistance and workability. Its lightweight nature makes it useful for aerospace structural applications such as fuselage skins, wing stringers, wing skins, etc.

Price: $

Delivery time: <10 days

Tolerance: ± 0.125mm (± 0.005 inches)

Maximum part size: 200 x 80 x 100 cm

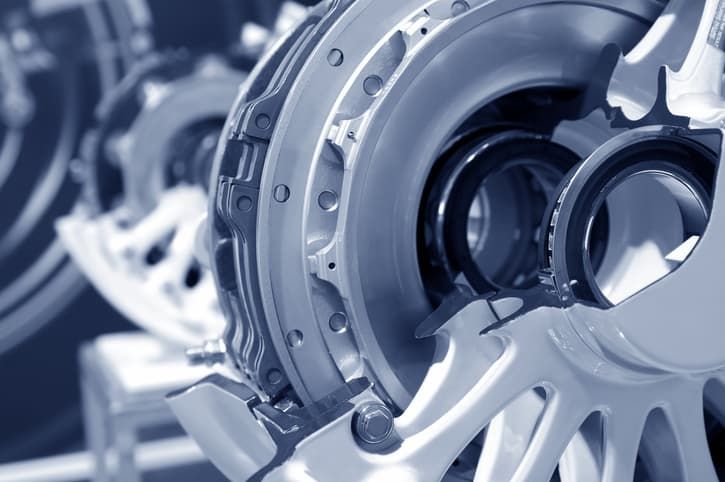

Titanium

Titanium

Titanium has many material properties that make it an ideal metal for demanding applications. These properties include excellent corrosion resistance, chemical resistance and resistance to extreme temperatures. The metal also has an excellent strength-to-weight ratio.

These properties make titanium alloys an excellent choice for airframes and aircraft engines.

Price: $$$

Delivery time: <10 days

Chamber wall thickness: 0.75mm

Tolerance: ± 0.125mm (± 0.005 inches)

Maximum part size: 200 x 80 x 100 cm

Stainless Steel

Stainless Steel

Stainless steel is a mild steel with properties sought after in many industrial applications. Stainless steel typically contains at least 10% chromium (by weight).

They are the best choice for engine and exhaust components, landing gear components, and critical joints in aircraft superstructure, ensuring high performance and durability.

Price: $$

Delivery time: <10 days

Chamber wall thickness: 0.75mm

Tolerance: ± 0.125mm (± 0.005 inches)

Maximum part size: 200 x 80 x 100 cm

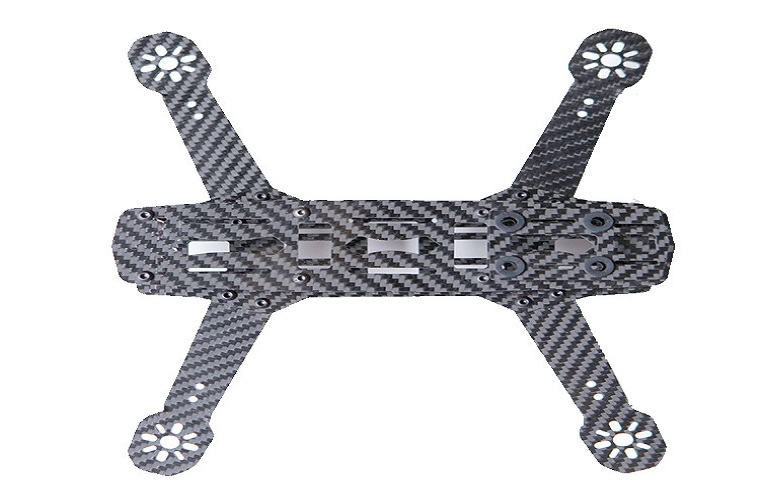

carbon fiber

carbon fiber

Carbon fiber reinforced polymers are widely used in the aerospace industry due to their high specific strength and stiffness. They also have higher fatigue and corrosion resistance, making them useful for structural components such as wing boxes, airframes and control surfaces.

liquid silicone rubber

liquid silicone rubber

Our liquid silicon material is an excellent choice for thermal stability and flexibility. They thrive in the extreme environments of the aerospace industry to ensure oil and fuel resistance.

Surface treatment of aviation parts

Get high-quality surface treatments for your aerospace components to improve the aesthetic quality of your products. Our excellent finishing services also improve the corrosion and wear resistance of these parts, while improving their machinery.

Name

Product Description

Materials

Color

Texture

Link

anodic oxidation

Anodizing improves corrosion resistance, enhances wear resistance and hardness, and protects the metal surface. Widely used in mechanical parts, aircraft, auto parts, precision instruments, etc.

Aluminum material

Transparent, black, gray, red, blue, gold

Smooth, matte finish

powder coating

A powder coating is a coating that is applied in the form of a free-flowing dry powder. Unlike traditional liquid coatings, which are delivered by evaporation of solvents, powder coatings are typically electrostatically sprayed and then cured under heat or ultraviolet light.

Aluminum, stainless steel, steel

Black, any RAL code or Pantone number

Gloss or semi-gloss

Electroplating

The plating may be functional, decorative or corrosion-related. This process is used by many industries, including the automotive industry, where chrome plating of steel automotive parts is common.

Aluminum, steel, stainless steel

Not applicable

smooth gloss

Polishing

Polishing is the process of creating a smooth and shiny surface through physical friction or chemical interference of parts. This process produces a surface with significant specular reflection, but in some materials can reduce diffuse reflection.

Aluminum, Brass, Stainless Steel, Steel

Not applicable

Smooth

Polishing

Brushing is a surface treatment process in which an abrasive belt is used to draw marks on the surface of a material, usually for aesthetic purposes.

ABS, aluminum, brass, stainless steel, steel

Not applicable

Satin

Aerospace Applications

Our manufacturing capabilities help accelerate the production of a wide range of aerospace components for unique applications. Here are some common aerospace applications:

Rapid Machining, Brackets, Chassis and Fixtures

Heat Exchanger

Custom Fixture

conformal cooling channel

Turbopump and manifold

Install inspection gauge

Fuel nozzle

Gas and Liquid Flow Components

Custom parts for the aerospace industry

Brands and businesses in the aerospace industry rely on our manufacturing solutions to meet their unique needs. From prototyping to mass production, we manufacture parts that meet industry performance and safety standards. Our spacious gallery showcases precision machined aerospace prototypes and production parts.