Quality Assurance

We design and manufacture various customized parts, provide 3/4/5 axis CNC machining services, provide CNC turning services, CNC turning and milling services, 3D printing services, vacuum casting services, EDM services and other machining services With 20 years of experience.

We have more than 120 high-end processing equipment, Mazak lathe, DMG and GF Mikron five-axis CNC machining, Hexcon three-dimensional coordinate measuring equipment and other high-end measuring equipment to ensure high processing accuracy and quality.

Our workshop.

Vacuum Casting Center

Testing Center

Surface treatment

CNC machining center

CNC lathe center

3D Printing Center

Production facilities

High-end Mazak CNC milling equipment 4 sets

Ensure the efficiency of parts in the processing process and reduce production time.

Avoid accuracy problems caused by workers and machines during processing, improve the accuracy and standard level of parts,

Combination of lathe and milling machine to realize double spindle work, reduce the number of machine tools and occupy workshop area

High-end GMF five-axis machining equipment 5 sets

Automatic tool change, data processing, can effectively reduce the number of workpiece clamping, reduce errors, improve processing accuracy, multi-process processing, can eliminate the error and positioning deviation caused by tool change, to ensure processing accuracy. Machining accuracy of each position

Five-axis CNC machine tools are the only means to solve the processing of impellers, blades, marine propellers, heavy generator rotors, turbine rotors, large diesel engine crankshafts, etc. In the design and development of complex curved surfaces, when the problem cannot be solved, it often turns to five-axis numerical control.

The five-axis CNC machine tool system has a decisive influence on a country's aviation, aerospace, military, scientific research, precision instruments, high-precision medical equipment and other industries.

5. High-end 5-axis processing equipment

GF Mikron MILL E 500/700 U

A maximum of 60 cuts. Up to 215 knife positions in the tower knife magazine

Machine work can be easily loaded knife

2. Torque motor or gear drive turntable

Direct drive motor to improve positioning accuracy and repeatability

3. Wider swing range, from -65 ° to 120 °

Reasonable tool length and workpiece relationship, easy access

4.20,000 rpm electric spindle, torque up to 120 Nm

High surface quality for both roughing and finishing

Other auxiliary equipment

Including milling machines, drilling machines, center-free grinding machines, cylindrical grinding machines, etc.

3D printing

SLA (stereolithography)

SLS (nylon powder laser sintering)

SLM (Metal Printing)

FDM (silk screen)

It is widely used in jewelry, footwear, industrial design, architecture, engineering and construction (AEC), automotive, aerospace, dental and medical industries.

The biggest advantage of 3D printing technology is that it can directly generate parts of any shape from computer graphics data without machining or any mold, thus greatly shortening the product development cycle, improving productivity and reducing production costs.

2. It can produce shapes that cannot be produced by traditional production techniques, and can design aircraft wings or heat exchangers more efficiently.

3. Compared with machine-made parts, printed products are 60% lighter in weight, but equally strong

Test Facility

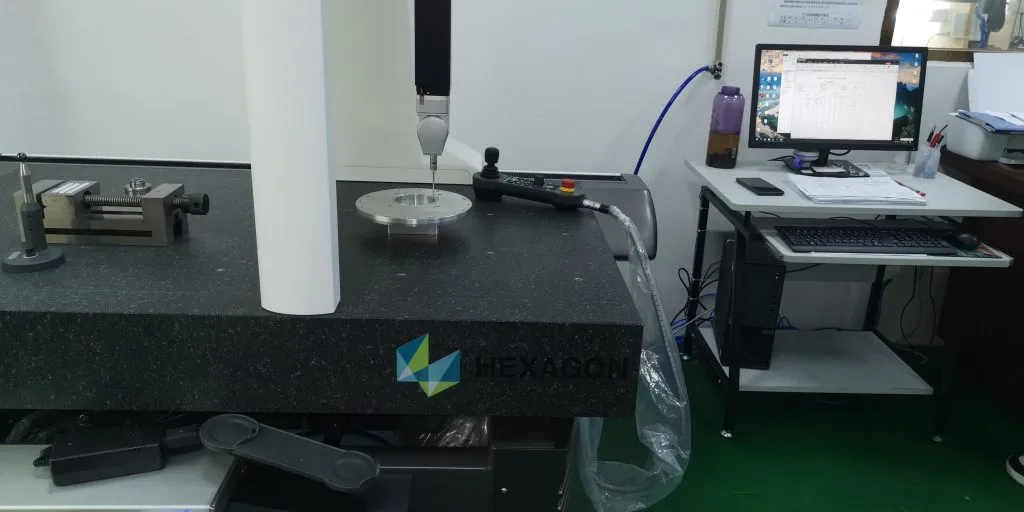

HEXAGON 3D coordinate measuring equipment

In order to ensure the quality of complex and precision products, the company has introduced advanced Hex Kang three-coordinate measuring instrument, which realizes convenient, fast and reliable geometric measurement, and can obtain the geometric size and tolerance data of the product in time, so as to provide guarantee for the manufacture of high-quality products. It mainly measures the form and position error of small and medium-sized mechanical parts, and is suitable for measuring room and production site.

It can be widely used in aviation, aerospace, weapons manufacturing, automobiles, engines, machine tools, molds, electronics and other industries that require complex spatial geometry measurement.

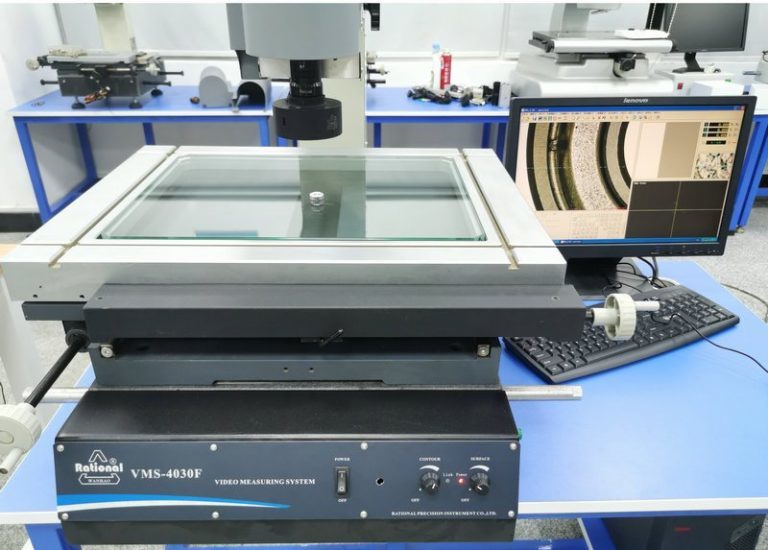

2.5 dimension measuring equipment

The 2.5-dimensional image measuring instrument is a flexible high-precision measuring device that can quickly and effectively complete any measurement and inspection tasks. By configuring various scanning and triggering measuring heads, it can meet various measurement requirements and become a simple, fast, efficient and high-precision measuring equipment. The image measuring instrument can better describe the outline of the product, thereby facilitating manufacturing.

Image measuring instruments are widely used in mobile phone parts, molds, electronics, communications, machinery, hardware and other precision manufacturing industries, enterprises, universities, scientific research institutes, measurement verification institutions and other units of the laboratory, measurement room and production workshop., gears, plastics, instrumentation, clocks, LEDs, PCBs and other industries, measurable materials include metals, materials, rubber, PCBs, ceramics, etc.