Vacuum casting services

Production level quality

ISO 9001:2015 certification

Powerful engineering and technical support

Vacuum casting for flexible and economical production

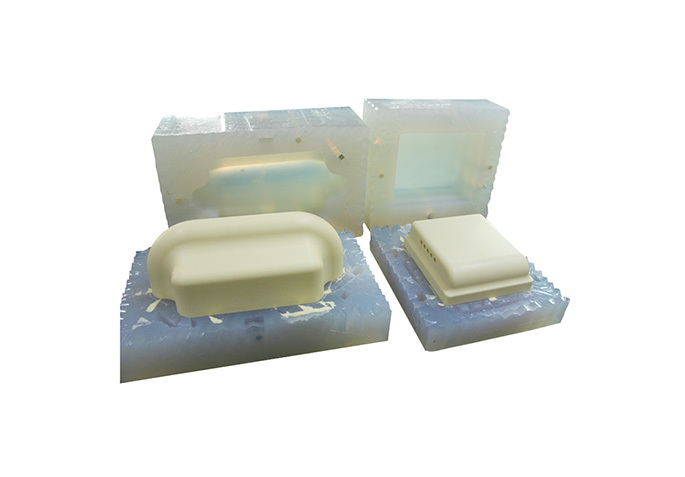

Vacuum casting or polyurethane casting is a technology that combines silicone molds and 3D printed master models to create short-term rigid parts with production-grade quality. This process hardens the thermoplastic polyurethane within the silicon or epoxy mold. The result is a vacuum cast part in the same shape as the original master model. The final dimensions of the vacuum cast part will depend on the master model, the part geometry, and the material selected.

As a leading manufacturer of vacuum casting, Youxenda provides low-cost manufacturing of high-quality plastic parts. This technology eliminates the need for expensive upfront investment. Our vacuum casting services provide a complete solution for creating high-quality prototypes and small-volume production parts.

Why Vacuum Casting

Professional vacuum casting experts

Our CNC precision machining combines advanced technology and expertise. As a ISO9001 certified company, we prioritize quality and ensure that components meet specifications

Complex geometry support

We use high-quality elastomer materials to ensure the manufacture of vacuum cast plastic parts of complex structures. Provide detailed design support to ensure that your prototype and small batch components closely resemble the intended final product.

Flexible color options

We carefully add a variety of color pigments to achieve the desired effect on your finished product. You can choose from our extensive list of color options.

Material and organization selection

Choose from a variety of possible materials and surface treatments for your vacuum cast parts. We offer the highest quality resins to ensure superior product quality and offer a wide range of surface treatment options to bring your products to life.

Consistent quality

Youxingda is proud to be ISO certified, ensuring that our products and services meet international quality standards. We provide manufacturing analysis and quality control to deliver parts that meet the highest standards.

Professional vacuum casting experts

Get reliable custom vacuum casting services from highly skilled and experienced experts. We have the best talent in the industry with expertise in manufacturing, material selection, surface treatment and more.

Vacuum casting from prototyping to production

Vacuum casting is the ideal solution for creating high-quality prototypes and small-batch parts for different applications. We help you achieve your manufacturing goals.

Model

The vacuum casting process involves low-cost tools to ensure that prototypes are created in an easier-to-use and more cost-effective manner. Create high-quality prototypes using a variety of materials and design changes. Easily test your designs and prepare them for functional testing.

Market testing

We help you create vacuum casting products suitable for market and consumer testing, concept models and user evaluations. These parts have high-quality finishes and end-use functionality. Our polyurethane casting services enable you to quickly integrate changes for further testing and market launch.

On demand production

Vacuum cast parts are an excellent choice for customization and first-run production. You can cost-effectively test product quality before starting full-scale production.

Vacuum casting tolerances

Youxenda offers a range of vacuum casting tolerances to meet your custom requirements. According to the main model and part geometry, we can achieve dimensional tolerances between 0.2 - 0.4 m. Below are the technical specifications for our vacuum casting services.

Type

Information

Accuracy

Maximum accuracy up to ± 0.05mm

Maximum part size

/- 0.025mm

/- 0.001 inches

Minimum wall thickness

1.5mm ~ 2.5mm

Quantity

20-25 parts per mold

Colors and Finishing

Color and texture can be customized

Typical Delivery Time

Up to 15 parts in 20 days

vacuum casting material

You can choose a wide range of vacuum casting materials according to the particularity of your project. These resins are generally analogs of common plastic materials with comparable properties and appearance. We have grouped our polyurethane casting materials into general categories to help you make the best decisions for your project.

Class ABS

Class ABS

A multifunctional polyurethane plastic resin similar to ABS thermoplastics. Hard, hard and impact resistant, it is an ideal choice for various products.

Price: $$

Color: All colors; provides accurate Pantone color matching

Hardness: Shore hardness D 78-82

Application: general items, shells

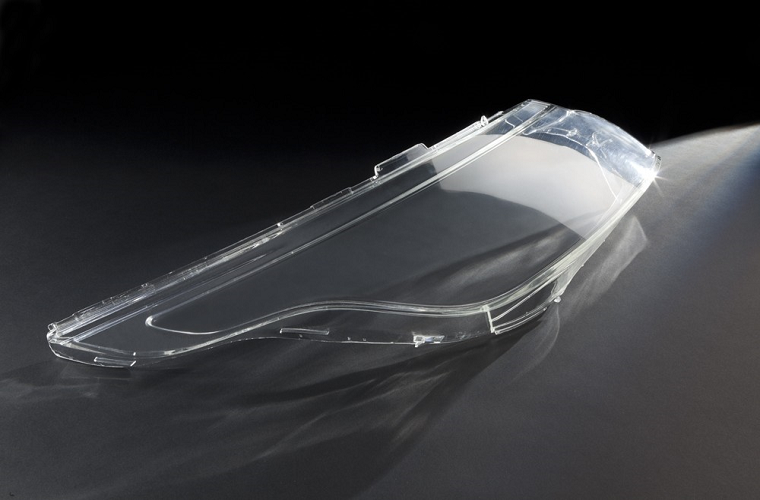

Acrylic

Acrylic

Hard, transparent polyurethane resin, simulating acrylic. Hard texture, high strength, good transparency, suitable for perspective products.

Price: $$

color: clearing

Hardness: Shore D 87

Application: light guide, perspective components

Polypropylene-like

Polypropylene-like

Tough, flexible and wear-resistant polyurethane with low cost and ductility similar to polypropylene.

Price: $$

Color: black or natural color only

Hardness: Shore hardness D 65-75

Applications: Enclosures, food containers, medical applications, toys

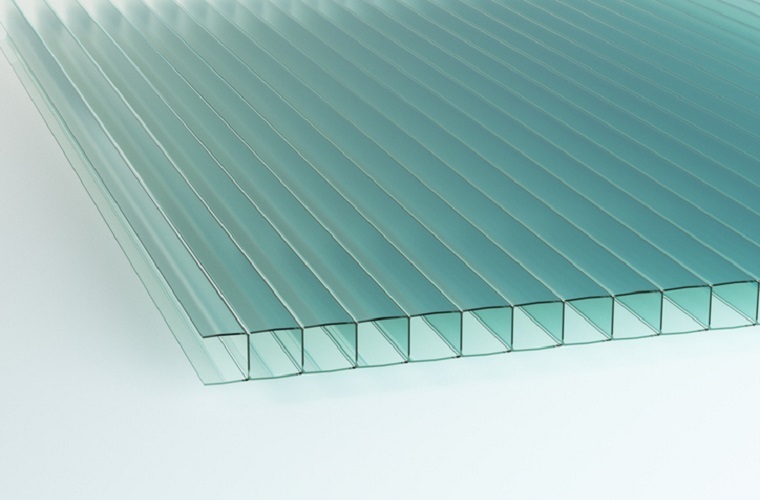

Class Polycarbonate

Class Polycarbonate

Rigid, high-strength and transparent materials with a wide range of uses. Easy to process and finish, simulates polycarbonate.

Price: $$

Color: clear and diverse colors

Hardness: Shore hardness D 82-86

Application: astigmatism, sign, sunroof, sun visor

PMMA

PMMA

UV stable high quality polyurethane resin, good transparency. Ideal for glossy, transparent parts, is a classic substitute for acrylic.

Price: $$

Color: RAL/Pantone color

Hardness: Shore hardness D 90-99

Application: lighting, signal display, partition material

PS

PS

High impact strength, low cost resin with a variety of options.

Price: $$

Color: Pantone

Hardness: Shore hardness D 85-90

Application: Disposables, Disposables, Packaging

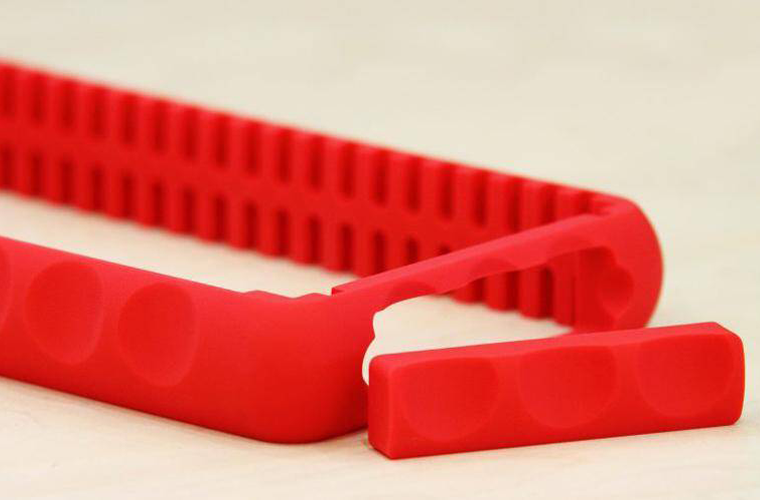

Elastomer

Elastomer

Polyurethane plastic resin, simulation of TPU, TPE, silicone rubber and other rubber materials.

Price: $$

Color: All colors and precise Pantone color matching

Hardness: Shore A 20 to 90

Application: wearable devices, secondary molding, gaskets

Surface Treatment of Vacuum Casting Parts

With a wide range of surface treatments, Youxingda can create a unique surface layer for your vacuum cast parts. These finishes help you meet the appearance, hardness and chemical resistance requirements of your products. According to your material selection and parts application, we can provide the following surface treatments:

Available Finishing

Product Description

SPI Standard

Link

high gloss

Highly reflective surface finish formed by polishing the primary pattern prior to mold making. The high-gloss finish provides high transparency and is suitable for decorative parts, lenses and other cleanable surfaces.

A1,A2,A3

semi-gloss

This Class B finish is not highly reflective, but has a certain luster. With sandpaper, you'll get a smooth, cleanable surface between high and matte.

B1,B2,B3

matt finish

Vacuum cast parts will have a satin-like finish by beading or sandblasting of the master model. The C- grade surface treatment is ideal for high-contact areas and hand-held components.

C1 C2,C3

Custom Edition

Youxenda can also provide custom finishes through other processes. Upon request, you can get a unique secondary finish for the best results.

D1、D2、D3

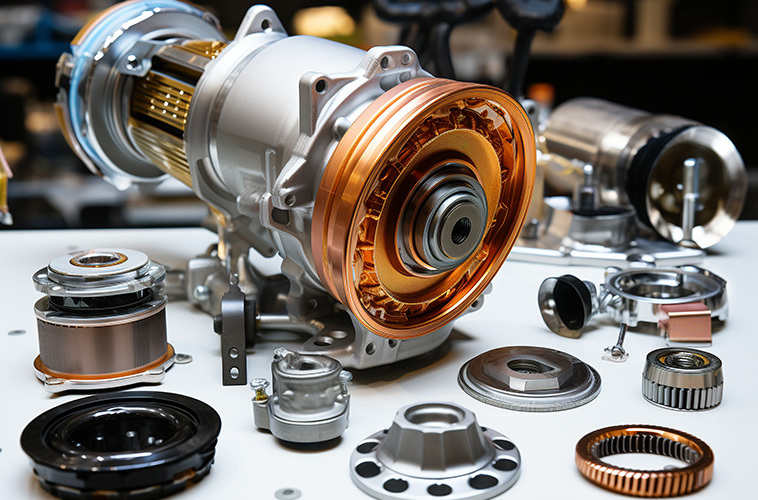

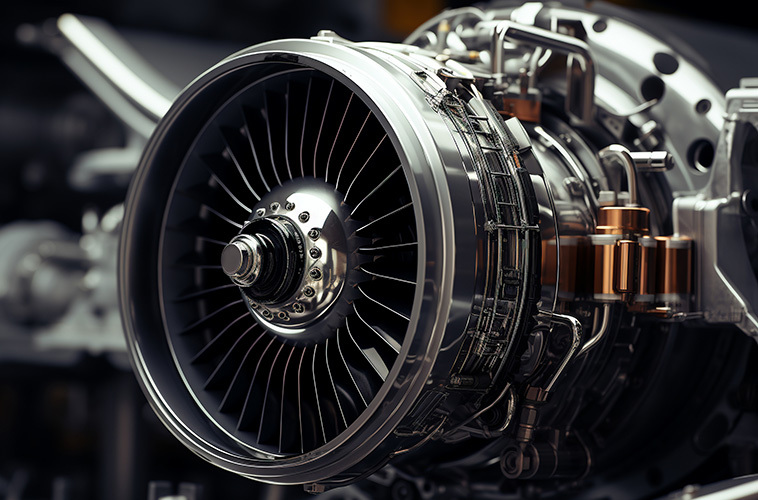

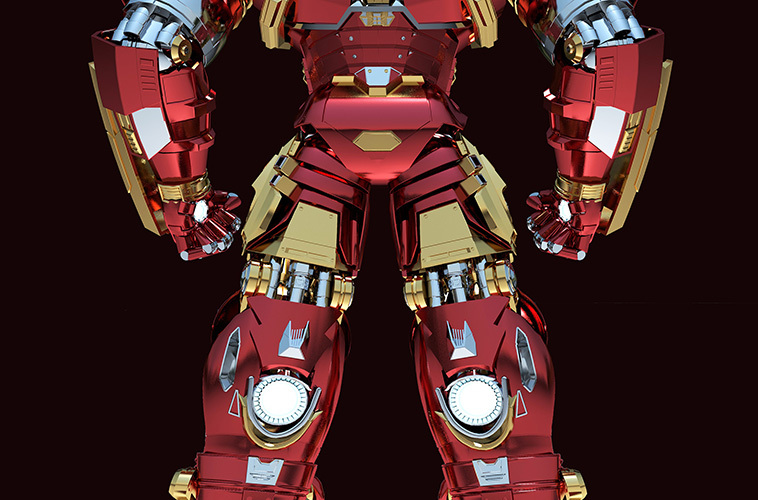

Vacuum Casting Gallery

Since 2009, we have been helping various industries such as aerospace, automotive, medical equipment and other industries to develop a variety of elastomer vacuum castings.

Vacuum Casting Parts Library01

Vacuum Casting Parts Library02

Vacuum Casting Parts Library03

Vacuum Casting Parts Library04

Our vacuum casting services for a wide range of industrial applications

Due to its fast production speed, low cost and durable parts, our vacuum casting service is the first choice for manufacturing customized parts for automotive, medical, consumer goods and other industries.

From aerospace to healthcare, our advanced 3D printing services translate concepts into high-performance prototypes and serialized production parts, optimizing manufacturing processes and unlocking new potential.