Laser cutting services

Free quotation within 1 day, DFM review

The fastest delivery time is 3-5 days

ISO 9001:2015 certification

Our custom laser cutting services

With outstanding manufacturing capabilities and more than 10 years of industry experience, Youxingda offers quality custom laser cutting services with the potential for outstanding results. We combine skilled mechanics with cutting-edge laser cutting equipment to cut anything from delicate aluminum foil to thick steel plates. Enjoy metal laser cutting services through a wide range of advanced processes and technologies.

Fiber laser cutting

With excellent precision, fiber laser cutting can produce excellent results on materials with a thickness of less than 20 millimeters. This process can help achieve more complex cutting operations, such as carving and annealing

Carbon dioxide laser cutting

Using highly advanced combinations of electricity and gas to cut non-metallic components such as plastic, acrylic, and wood. This laser cutting process can also provide excellent cutting effects on thin aluminum plates and other non-ferrous metals.

Nd: Yag laser cutting

This high-power laser cutting process provides more advanced online laser cutting services for coated and uncoated metals, plastics, and other non-metals. Enjoy top-notch laser cutting parts that have a longer expected lifespan and the best quality.

Check the metal laser cutting process in Youxingda.

Youxingda offers a premier custom laser cutting service. Our capabilities and facilities ensure that we get the best results on a variety of projects.

Advantages of laser cutting

Laser cutting brings many benefits to many industries, including precision, speed, repeatability and flexibility. Youxingda's laser cutting services help meet the functional and aesthetic requirements of the industry.

High-precision cutting: The beam involved in laser cutting ensures high-precision melting and evaporation of the material, ensuring accuracy as low as 0.003mm.

Maximum plate utilization: Laser cutting technology maximizes the number of available metal plates, with almost no wasted space, ensuring that only accurate quantities of material are provided.

High cutting versatility: Through advanced laser cutting operations, you can obtain customized laser-cut parts with simple cutting, marking, engraving and complex details.

Low power use: The sheet metal laser cutting machine can effectively cut the material block without consuming too much energy, usually only using 10kW of energy.

Almost no damage: The heat generated by the laser cutting process has very little effect on the parts and has no effect on the tolerances of the laser cutting parts.

Laser cutting standard

Youxingda follows international industry standards and market trends to provide our customers with high-quality laser-cut parts. We have the most advanced laser cutting machine, which can provide the finest and most accurate cutting. These technologies allow us to cut at a higher speed, with multiple design changes, narrow cuts, burr-free edges and holes, and less material waste, all at a lower cost.

Standard

Product Description

Minimum part size

10 mm(0.40 in。)

Minimum feature size

2 times the thickness of the material, the minimum thickness is 1mm (0.04 inches)

Distance dimension

Our laser cutting standards are based on ISO 2768-c.

Typical dimensions: /- 0.2mm (0.008 inches) length, width, diameter and position.

Maximum material thickness

Carbon steel <25mm (0.98 inches), stainless steel <15mm (0.59 inches), aluminum <15mm (0.59 inches), copper <12.7mm (0.5 inches)

Cutout (slit size)

Approximately 0.5mm (0.02 inches)

edge condition

Laser cut edges have matte and vertical lines.

laser source

CO2 and fiber lasers. Up to 10 kW.

Repeatability

/- 0.05mm (0.002 inches)

Positioning accuracy

/- 0.10mm (0.004 inches)

Delivery time

5-7 days

Laser cutting materials

Youxingda's laser cutting services are versatile and suitable for a variety of materials, from ferrous metals to non-ferrous metals, plastics and other non-metals. Our laser cutting equipment combines ultra-modern technology with skilled professionals to laser cut materials of different strength, weight and thermal properties. Here are some laser cut materials that can be used for your project.

Metal Products

Metal Products

Utilize our wide range of metal materials for your laser cutting projects. Our production-grade metals have high strength and durability, optimal thickness and customizability. As the most common laser cutting material, Youxingda offers a long list of metals, including:

Type:

Aluminum material

Stainless Steel

Iron piece

Copper

Plastic

Plastic

There are also many plastics that are compatible with the laser cutting process. We offer a wide range of plastics to meet simple commercial applications and complex industrial requirements. Youxingda's production-grade plastics are an excellent choice for medical devices, gears, food packaging and more. Common ones include:

Type:

PMMA

Polyoxymethylene (POM, acetal)

Polyethylene

Polypropylene

Styrene

Lucite

Polyester film (polyester)

Acrylic

Acrylic

Our acrylic laser cutting services have a wide range of value to help you meet the needs of your industry for a wide variety of applications. Our improved technology allows us to cut and engrave on acrylic materials to achieve the best results. Youxingda offers cast acrylic materials and extruded acrylic materials to meet your production requirements.

Finishing options for laser cutting

Choose from an extensive list of finishing options to improve the surface of custom laser-cut parts and products, thereby improving their appearance, corrosion resistance and durability.

Name

Product Description

Materials

Color

Texture

Link

anodic oxidation

Anodizing improves corrosion resistance, enhances wear resistance and hardness, and protects the metal surface. Widely used in mechanical parts, aircraft, auto parts, precision instruments, etc.

Aluminum material

Transparent, black, gray, red, blue, gold.

Smooth, matte finish.

Sand blasting

The surface of the parts after sandblasting is smooth and has a matte texture. It is mainly used for vision applications and can be followed by other surface treatments.

ABS, aluminum, brass, stainless steel, steel

Not applicable

Matte

powder coating

A powder coating is a coating that is applied in the form of a free-flowing dry powder. Unlike traditional liquid coatings, which are delivered by evaporation of solvents, powder coatings are typically electrostatically sprayed and then cured under heat or ultraviolet light.

Aluminum, stainless steel, steel

Black, any RAL code or Pantone number

Gloss or semi-gloss

Electroplating

The plating may be functional, decorative or corrosion-related. This process is used by many industries, including the automotive industry, where chrome plating of steel automotive parts is common.

Aluminum, steel, stainless steel

Not applicable

smooth gloss

Polishing

Polishing is the process of creating a smooth and shiny surface through physical friction or chemical interference of parts. This process produces a surface with significant specular reflection, but in some materials can reduce diffuse reflection.

Aluminum, Brass, Stainless Steel, Steel

Not applicable

Smooth

Polishing

Brushing is a surface treatment process in which an abrasive belt is used to draw marks on the surface of a material, usually for aesthetic purposes.

ABS, aluminum, brass, stainless steel, steel

Not applicable

Satin

Laser cutting for various applications

Many industries around the world are gradually transitioning to laser cutting technology because it provides additional benefits such as precision, tight tolerances, flexibility, finish, increased productivity and design complexity. Whether it's prototyping or full-scale manufacturing, switching to laser cutting saves time and money.

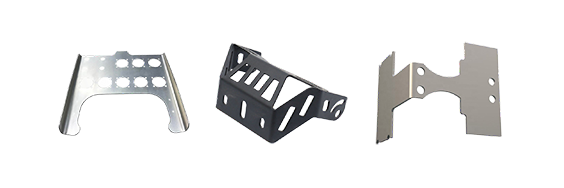

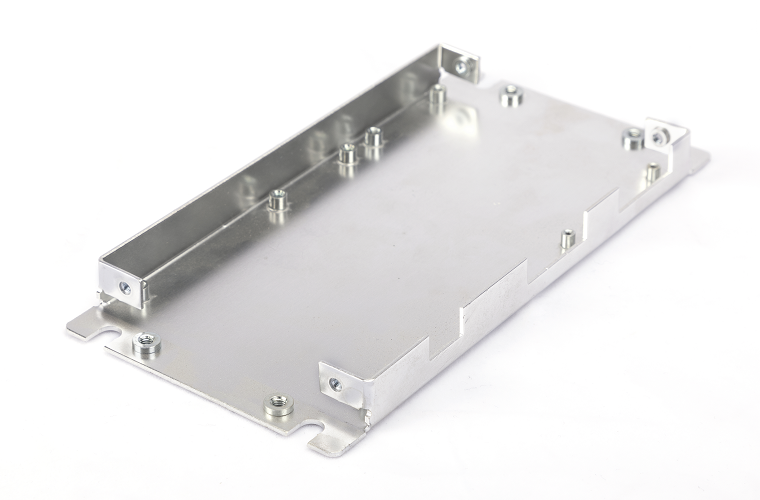

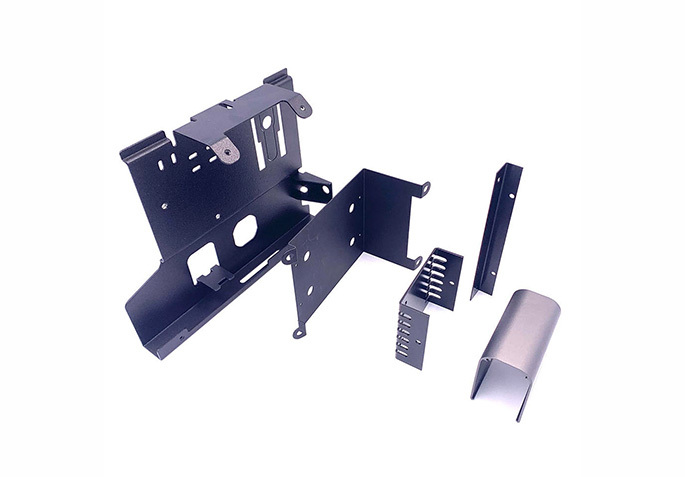

Sheet Metal Laser Cutting Parts Gallery

Over the years, Youxingda's laser cutting services have covered a wide range of applications in many industries. Here are some of our previous laser cutting projects.

Sheet metal laser cutting part library01

Sheet metal laser cutting part library02

Sheet metal laser cutting part library03

Sheet metal laser cutting part library04

Why choose us for laser cutting

With cutting-edge laser cutting technology and innovative technical expertise, Youxenda is committed to providing the best custom laser cutting services through prototyping and mass production runs. We are a reliable manufacturing company with the appropriate certification and experience to provide cost-effective on-demand laser cutting solutions.

Sheet metal engineering support

With an ISO 9001:2015 certified sheet metal manufacturing plant, we can provide materials and full-size inspection reports according to your requirements. You can always rest assured that the parts you get from Youxingda will exceed your expectations.

Strong manufacturing capabilities

Our domestic factory in China provides complete sheet metal project solutions for small and high volume production through flexible materials, surface finish options and unlimited manufacturing capabilities.

Sheet metal engineering support

We offer 24/7 online engineering customer support for your custom sheet metal engineering and manufacturing problems. This includes case-by-case recommendations to help you reduce costs early in the design phase.