Rapid prototyping services

Various rapid prototyping services

Rich materials and finishes

24/7 Engineering Support

1 day

Tolerance

12

Surface treatment

30%

Low price

0.005 mm

Tolerance

Superior Rapid Prototyping

Rapid prototyping is a product development method that allows production and iteration of product parts for evaluation and testing. By manufacturing your rapid prototypes with Youxenda Assurance, you can make the best decisions about your design. We let you test a variety of materials and finishes so you can make an informed decision on how to move forward with your project. We have a range of rapid prototyping processes for you to choose from.

Rapid CNC machining

Why Choose Our Rapid Prototyping Services

Our high-quality rapid prototyping service guarantees fast delivery times, ensuring that you receive your products and parts before the deadline at the lowest mold cost.

Consistent high quality

We use high-quality input materials and maintain a high level of process stability to ensure repeatability. We strive for continuous improvement to improve our ability to manufacture, process and deliver goods.

Strong manufacturing capabilities

To meet your rapid prototyping needs, we offer and support a wide range of manufacturing capabilities. For low-volume CNC machining, injection molding, 3D printing and other services, our goal is to bring your prototype or part to life in the best way.

Fast delivery time

We have a state-of-the-art in-house production supply chain and the strength of our people to help us meet and exceed your expectations for delivery times and quantities. We make sure all our deliveries are within the schedule.

Establish a supply chain system

Our leading suppliers help us receive materials for continuous production while ensuring that the cost of each product is affordable.

Powerful engineering and technical support

Our team of experienced experts is ready to provide professional advice and advice on your orders, improvements and preferences.

Our rapid prototyping capabilities

Rapid CNC machining

Rapid CNC machining

CNC machining is an ideal production choice for rapid prototyping of plastic and metal parts, as we can create prototypes with all the precise details you need and complete them in a short delivery time.

| Type | tolerance |

|---|---|

| Linear dimensions | +/- 0.025 mm (+/- 0.001 in.) |

| Aperture (unreamed) | +/- 0.025 mm (+/- 0.001 in.) |

| Shaft diameter | +/- 0.025 mm (+/- 0.001 in.) |

| Part size limitations | 950*550*480 mm (37.0*21.5*18.5 inches) |

Rapid injection molding

Rapid injection molding

Our validated injection molding process is very suitable for creating small batch molds and plastic parts tasks. In addition to injection molding, we also apply secondary processing and other technologies to produce impressive products for your brand.

| Standard Capability | Product Description |

|---|---|

| Mold cavity tolerance | ± 0.05 millimeters |

| Standard delivery time of | 15 working days or less |

| Repeatability between parts | ± 0.1 millimeters |

| Production level | 1-100000 cycles |

Rapid sheet metal manufacturing

Rapid sheet metal manufacturing

Using RapidDirect's streamlined sheet metal processing to produce metal parts. The combination of advanced equipment and internal production ensures shorter delivery times and strict quality standards.

| Dimensional details | tolerance |

|---|---|

| Edge-to-edge, single-sided/edge-to-hole, single-sided/hole-to-hole, single-sided | +/- 0.005 inches |

| Bend to edges/holes, single-sided | +/- 0.010 inches |

| Edge to feature, multi-surface/over-formed part, multi-surface | +/- 0.030 inches |

| Bending angle | +/- 1° |

Quick 3D printing

Quick 3D printing

Youxingda adopts the latest 3D printing technology to meet your fast 3D printing needs, such as SLA, SLS, FDM, etc. With our fast production capacity and simplified processes, you can guarantee to receive customized parts within a few days.

| Standard Competencies | Product Description: |

|---|---|

| minute wall thickness | 1.0 mm |

| Floor height | 50 - 300μm |

| Maximum. Build dimensions | 250*250*250 mm(SLA), 420*500*420mm(SLS), 500*500*500mm(FDM) |

| tolerance | ± 0.5% with ± 0.5 mm (± 0.020") |

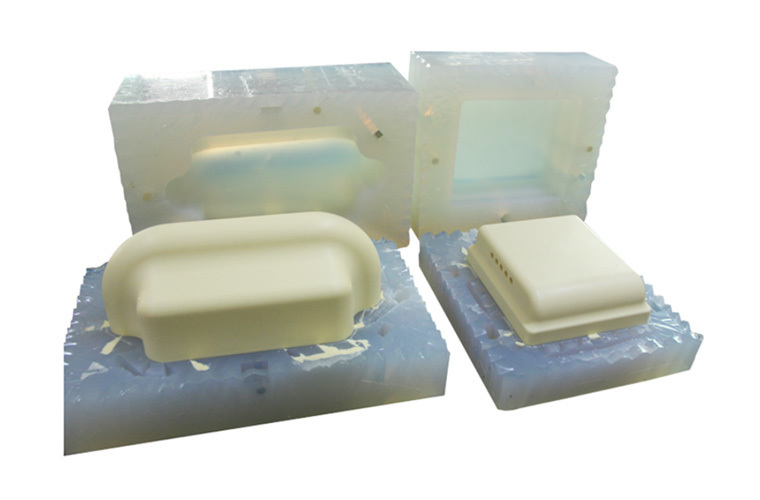

Rapid vacuum casting

Rapid vacuum casting

If you are looking for a fast and reliable source of elastic plastic parts, Youxingda can meet your needs. Our vacuum casting process can provide plastic parts with stable quality, complex details, and impressive results.

| Standard Competencies | Product Description: |

|---|---|

| Maximum build size | +/- 0.025 mm (+/- 0.001 in.) |

| Standard delivery time | Up to 15 parts in 20 days |

| Dimensional accuracy | ± 0.05 mm |

| Layer thickness | 1.5mm - 2.5mm |

Material Selection for Rapid Prototyping

We offer offers in over 100 metals and plastics to meet your prototyping needs. On our platform, you can also view different materials and their processing costs.

Metal Products

Metal Products

There are different types of metals, each with different physical and chemical properties. These differences make certain metals more suitable for specific applications than others. Methods for making metal prototypes include: CNC machining, casting, 3D printing, and sheet manufacturing.

Brass Titanium

Aluminum Copper

Stainless Steel

Plastic

Plastic

Plastic is a broad term that encompasses a variety of materials. Most of them have advantageous properties that make them ideal for rapid prototyping, including ease of molding, insulation, chemical resistance, abrasion resistance, and light weight.

Plastic production methods Prototype parts include; polyurethane casting, 3D printing and CNC machining.

ABS 尼龙 (PA) PC PVC

PU PMMA PP PEEK

PE High Density Polyethylene PS POM

Types of Rapid Prototyping

The R rapid prototyping process is far-reaching, covering a wide range of materials, technologies and industries. There are four different types of rapid prototypes.

Conceptual model

Display prototype

Functional prototype

Pre production prototype

From rapid prototyping to production

Having been in the prototyping and production industry since 2009, we help startups and well-known brands to manufacture competitive prototypes and products in the global market. This is a testament to the quality and precision of our machines, as well as a team of experienced professionals working tirelessly to ensure your quality products come to market on time.

At Youxinda, we provide first-class services covering all aspects of manufacturing, from prototyping to production. Our rapid prototyping services include injection molding, rapid 3D printing services, CNC rapid machining services, plastic extrusion and sheet manufacturing, considering your ideal prototyping material. Our rapid prototyping and production services greatly reduce your production costs while shortening your time to market. So partner with us today to meet all your needs, from prototyping to production needs.

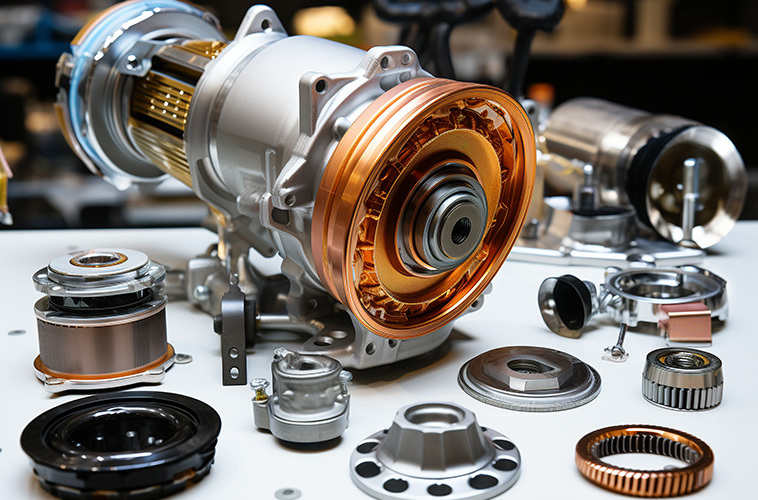

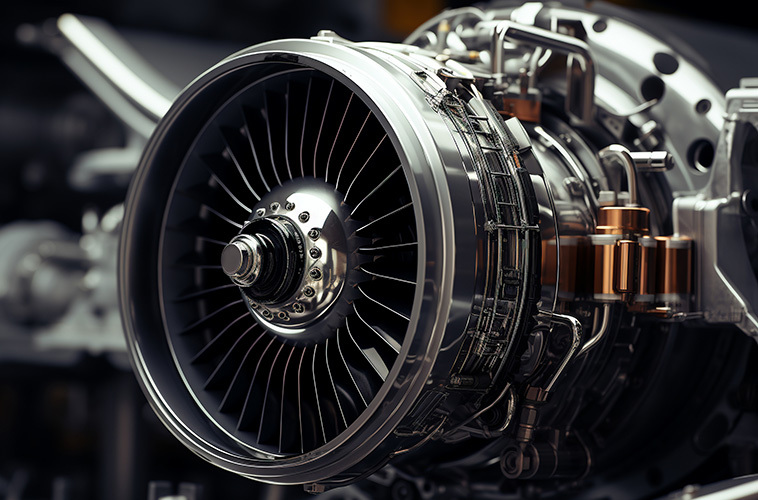

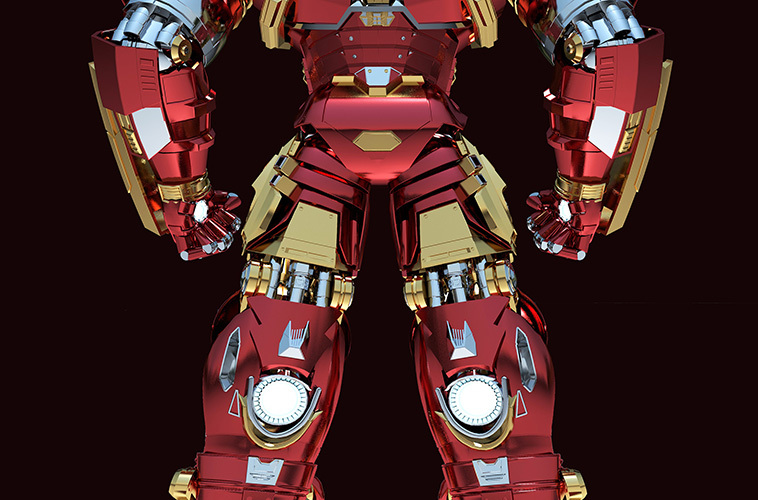

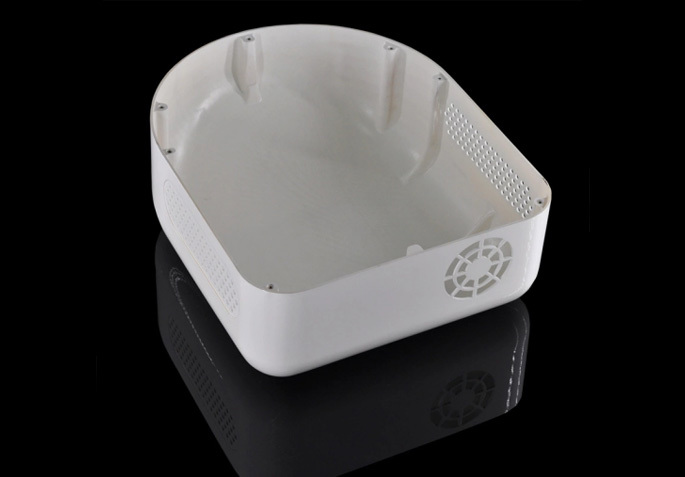

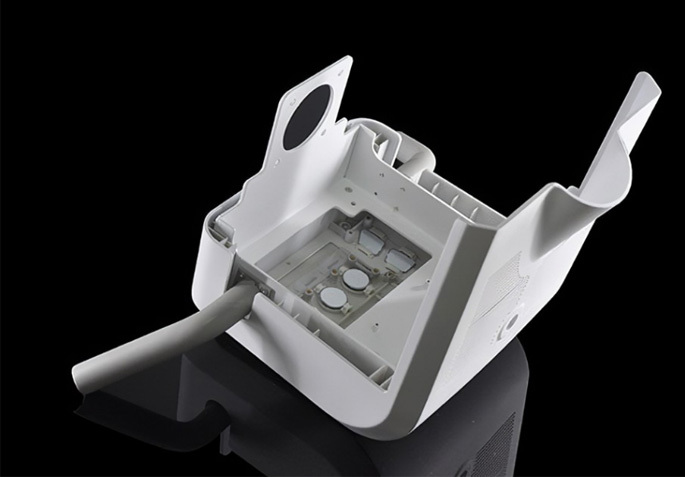

Rapid Prototyping Parts Gallery

Since 2009, we have produced prototypes for various industries, including medical, automotive, aerospace, construction and other industries.

Rapid prototyping component library01

Rapid prototyping component library02

Rapid prototyping component library03

Our rapid prototyping for a wide range of industrial applications

Many industries, such as the medical and food service sectors, rely on Youxingda's rapid prototyping capabilities to meet their growing demand for parts used on critical production equipment.