Rapid prototyping and on-demand production

Medical device industry

High precision medical products

ISO 13485:2016 certification

24/7 Engineering Support

Why Youxingda is used in the medical industry

Youxenda provides reliable medical device prototype design and production, from simple to complex medical components. Combining advanced technology and superior manufacturing expertise, we can bring your medical products to life in the most effective way. Regardless of the complexity of the part, we can help you achieve your goals through rapid prototyping, bridge tools and low-volume production.

Strong strength

We are a company certified by ISO 13485:2016 and ISO 9001:2015, which shows that we have the best manufacturing capabilities, correct material certification and advanced technology. All of Youxingda's medical equipment components meet regulatory requirements in terms of size, performance, and strength.

Precision parts

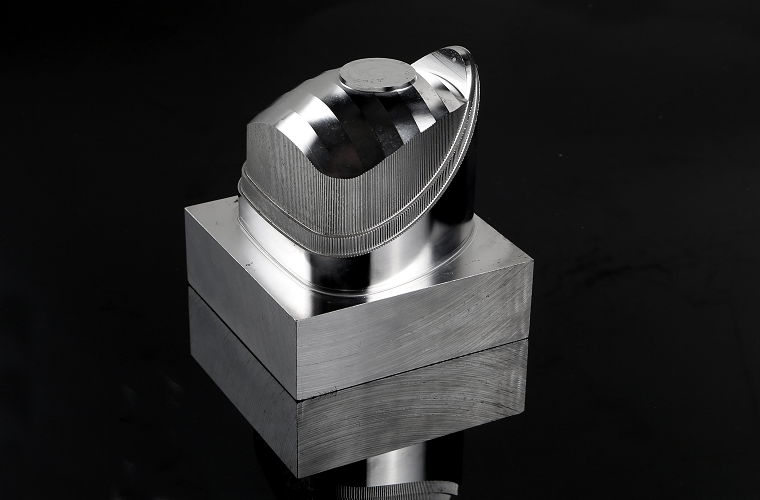

Our medical device prototyping services provide parts that meet tolerance and precision requirements. We can manufacture medical components with tolerances up to/-0.001 inches. Our processing technology and expertise also help us ensure the accuracy of your medical device prototypes.

Fully customizable

Youxenda can accelerate medical parts manufacturing through our custom design and custom tooling capabilities. We will work with you to analyze the uniqueness of your product and then use high-tech manufacturing processes to bring the concept to life.

Fast delivery time

With instant quotations and rapid prototyping technology, Youxenda can help you reduce delivery time by more than 50%. Our extensive technical experience and skills help us to achieve this in the most effective way possible.

We are ISO 13485 certified!

Youxinda has ISO 13485 certification, a management system standard designed for medical device manufacturing. This indicates that all medical device prototypes and components you obtain from us are in full compliance. It also demonstrates our quality control and assurance system to assure you that we will manufacture components according to your specific needs. We are ready to serve every customer in the dental, biotechnology, surgical and pharmaceutical industries.

From prototyping to the production phase in the medical industry

Take advantage of top solutions for medical product development. Youxenda provides professionally designed and manufactured customized products with excellent durability and functionality. We offer these solutions at different stages to help you achieve your production goals.

Model

Model

Create high-quality prototypes for early development using production-grade materials. Analyze your design and make the right design or material changes to prepare the medical prototype for testing.

Model

After analyzing your design files, our technicians will create a prototype to meet your design requirements. Your application will determine the materials and processes we will use to develop your component to make it look like the final product. This allows you to evaluate the specification and perform functional tests.

Rapid material and design changes

Accurate prototypes with complex geometries

Prototype model approaching the final component

Engineering Validation and Testing (EVT)

Engineering Validation and Testing (EVT)

Make quick and easy changes to functional medical device prototypes after engineering testing and validation of performance requirements.

EVT

We create functional prototypes similar to the final product. This way, you can easily identify design problems and correct them. Some changes may be required to ensure that performance requirements are met.

High Precision Prototype Manufacturing

Optimized design and engineering support

Optimized design and material selection

Design Validation and Testing (DVT)

Design Validation and Testing (DVT)

Validate the performance, functionality and appearance of your medical products in the most effective way possible. Make necessary design iterations to save production time and cost

DVT

We provide best-in-class manufacturing feedback designs to help you analyze the performance and appearance of your medical prototypes. With a wide range of materials, finishes and mechanical designs, we will create components with ideal end-use functions and finishes for market testing.

Quality prototypes for market testing

Functional and appearance verification

High quality surface treatment

Production Validation and Testing (PVT)

Production Validation and Testing (PVT)

Make your designs ready for mass production using production-grade processing and advanced quality management systems.

PVT

Control your product design based on technical team feedback. In this way, you can evaluate the manufacturability and suitability of the product, and make the final changes to improve production efficiency.

Manufacturing Process Validation

Fast and small batch production tools

Fast delivery of quality production parts

Production-level design iteration

Mass Production

Mass Production

Migrate from the product testing phase to full-scale production of end-use medical components. The use of precise quality requirements and excellent manufacturing capabilities to create high-quality products.

Mass Production

We take your medical device production to the next level with our advanced manufacturing processes and engineering expertise. Our experts are committed to ensuring that your products meet quality and performance requirements at low cost and faster delivery times.

Quality Medical Devices

Precision machining with tight tolerances

Excellent post-processing operation

In-depth quality management system

Trusted by Fortune 500 companies

Health Care Institutions

Hospital Operator

Biotechnology Company

Pharmaceutical Company

Medical Delivery System Suppliers

Life science

Diagnostic Equipment Manufacturers

Surgical Equipment and Robotics Company

Medical Device Manufacturing

The medical industry relies on precisely manufactured products to safeguard human health. Our ISO 13485 certification indicates that we provide accurate, high-quality medical components that meet regulatory and quality standards. Enjoy reliable and professional medical device manufacturing solutions to customize products to the highest quality standards.

CNC machining

Injection molding

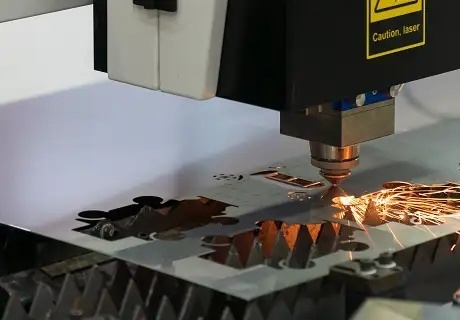

Sheet metal processing

3D printing

Materials for Medical Product Development

Our manufacturing technology is compatible with a wide range of materials to meet the needs of the medical industry. Our technicians also have sufficient experience and knowledge in the right materials for medical product development, and we will work with you to choose the materials that best meet your requirements. Take a look at some of the most popular materials used to develop medical device components.

Thermoplastic

Thermoplastic

Thermoplastics are highly durable, flexible and functional materials used in the manufacture of medical products. Their excellent corrosion resistance, detergent resistance and chemical resistance make them last longer than other typical medical materials. Thermoplastics also adhere strongly to metals, which makes them useful for overmolding medical prototypes to improve functionality.

Thermosetting

Thermosetting

Thermosetting plastics have high heat resistance and will not warp or creep under high temperature conditions. This makes them an excellent choice for medical devices that may require continuous sterilization. They are also relatively hard and rigid with excellent dimensional stability to ensure accurate and precise assembly.

Nylon

Nylon

Polyamide materials have higher strength, high temperature resistance and chemical resistance, which is required for medical devices. It is also compatible with processes such as injection molding, CNC machining and 3D printing. We can also combine nylon with other medical grade materials to increase its strength.

Silicone rubber

Silicone rubber

Silicone rubber has the advantage of higher thermoset. Due to its high thermal stability and flexibility, it meets industry standards. Therefore, it can be easily sterilized by various methods. The material is also very stable and maintains its flexibility even under extreme conditions.

Titanium

Thermoplastic

Titanium offers a higher strength-to-weight ratio and higher corrosion resistance, making it ideal for prototyping medical devices. It works perfectly with 3D printing to create custom parts based on a patient's body scan. Titanium also has a variety of properties that enhance its resistance to chemicals and extreme temperatures.

Stainless Steel

Thermoplastic

Titanium has many material properties that make it an ideal metal for demanding applications. These properties include excellent corrosion resistance, chemical resistance and resistance to extreme temperatures. The metal also has an excellent strength-to-weight ratio.

Price: $$$

Delivery time: <10 days

Chamber wall thickness: 0.75mm

Tolerance: ± 0.125mm (± 0.005 inches)

Maximum part size: 200 x 80 x 100 cm

Post-processing of medical prototypes and products

With a wide range of reprocessing options, Youxingda can provide unique surface treatments for your medical prototypes and products to meet the aesthetic and chemical and corrosion resistance needs of your products. Depending on material selection and product application, we offer the following finishes.

Name

Product Description

Materials

Color

Texture

Link

anodic oxidation

Anodizing improves corrosion resistance, enhances wear resistance and hardness, and protects the metal surface. Widely used in mechanical parts, aircraft, auto parts, precision instruments, etc.

Aluminum material

Transparent, black, gray, red, blue, gold

Smooth, matte finish

powder coating

A powder coating is a coating that is applied in the form of a free-flowing dry powder. Unlike traditional liquid coatings, which are delivered by evaporation of solvents, powder coatings are typically electrostatically sprayed and then cured under heat or ultraviolet light.

Aluminum, stainless steel, steel

Black, any RAL code or Pantone number

Gloss or semi-gloss

Electroplating

The plating may be functional, decorative or corrosion-related. This process is used by many industries, including the automotive industry, where chrome plating of steel automotive parts is common.

Aluminum, stainless steel, steel

Not applicable

smooth gloss

Bead spray

The pearlescent treatment makes the material look smoother, shinier and cleaner. It has been used on a wider range of materials, including metal, plastic, rubber and glass.

Aluminum, stainless steel, thermoplastics

Gray, black

Smooth, Matte

passivation

Passivation helps reduce corrosion, oxidation and mild chemical attack on stainless steel. It also helps to enhance the beauty of this metal.

Stainless steel, aluminum, titanium

Yellow, transparent blue, green, black

Smooth, matte, semi-gloss

Heat treatment

Heat treatment makes it easier to weld parts and improves the mechanical properties, strength and flexibility of the material. It can also improve brittleness and wear resistance.

Titanium, aluminum, stainless steel

Light yellow, brown, straw

Smooth, Matte

Medical Applications

Our extensive manufacturing capabilities allow us to improve the production of medical devices to serve many healthcare applications. Some applications include:

Handheld Devices

Surgical instruments

Medical Testing Equipment

Medical Delivery Systems

Ventilator

Implantable Prototype

Prosthetic components

microfluidics

UV Sanitary Components

Custom prototypes and parts for the medical device industry

Several leading medical device companies rely on our outstanding medical prototyping and production solutions to customize their medical parts. Our manufacturing capabilities and quality management systems ensure that the components we produce meet performance and safety standards.