Plasma cutting services

Free quotation within 1 day

The fastest delivery time is 3-5 days

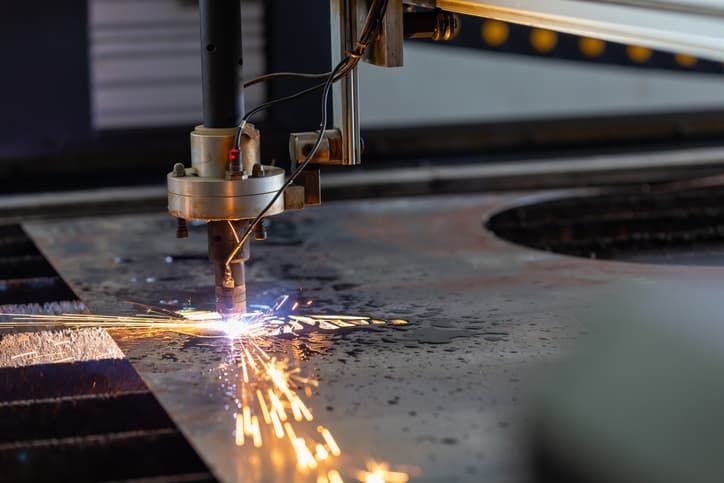

What is plasma cutting?

Plasma cutting is a production process that involves the use of ionized gas at temperatures above 20,0000C to melt and remove material from the workpiece. The gas used herein includes argon/hydrogen, argon or nitrogen. Plasma cutting is ideal for manufacturing high-precision parts with general applications and specific industry applications. When manufacturing your product parts, you can get many benefits by using Youxingda's custom plasma cutting services. Some of these advantages include:

High accuracy and repeatability: Accuracy and repeatability are one of the main advantages of our plasma cutting services. This is especially true when cutting shapes and angles from metal workpieces. At Youxingda, we have experienced operators whose hands are stable and can guarantee clean and high-precision cutting.

Versatility for various materials: Versatility is one of the main advantages of using plasma cutting to manufacture metals. This is because it can cut conductive metals such as iron, copper, stainless steel, steel, brass and other metals. In addition, plasma cutting has one of the fastest cutting speeds, making it one of the best methods for metal processing.

Suitable for different thicknesses: Unlike other metal cutting options, CNC plasma cutting can cut metals of various thicknesses. Our plasma cutting team in Youxinda can cut metal up to an inch and a half or more thick.

Complex shapes: Plasma cutting helps to create a variety of shapes, regardless of the complexity of their geometry. At Youxinda, we use plasma cutting to make complex shapes, straight lines and curves that cannot be made using other metal cutting technologies.

Energy efficiency: Energy efficiency is one of the reasons why more and more companies and enterprises are leaning towards plasma cutting. At Youxingda, our CNC plasma machine is very energy-efficient and can save long-term running costs.

Plasma cutting from prototyping to production

Youxingda's custom plasma cutting services can be used for a variety of applications, such as mold processing, rapid prototyping and custom manufacturing.

Rapid prototyping

Create prototypes with complex details and fine features that may be difficult to achieve using other cutting methods. Allows fast turnaround time and reduces overall production time.

On demand production

Create fast and precise cuts for a variety of materials. This can include creating test pieces, evaluating designs, and producing a small number of products for testing and validation.

On demand production

Create precise cuts for mass production. Our plasma cutting machines are available in various sizes and configurations for cutting both thin and thick metals.

plasma cutting ability

Youxenda is committed to meeting and exceeding customer requirements and industry standards. Regardless of the material type and design complexity, our high-precision plasma cutting machines can cut with the highest accuracy and precision.

Standard

Product Description

Thickness

Aluminum ≤ 40mm, steel ≤ 50mm, stainless steel ≤ 50 mm

Cutting tolerance

The standard tolerance range for plasma cutting is between 0.1 and 0.2mm. This tolerance level depends primarily on the dimensions and general requirements of the part. However, in RapidDirect, we will adjust our tolerance level to meet customer requirements.

Cutting area

The cutting area of thin aluminum plates up to 4mm thick is 1000 x 2000mm, 1250 x 2500 mm and 1500 x 3000mm. The cutting area of thick steel plate above 4mm is 1500 × 3000mm, 2000 × 3000mm, 1500 × 6000mm.

Delivery time

5 days or more

plasma cutting materials

Youxinda's CNC plasma cutting services are available for a wide range of materials. Regardless of the thickness, the hot gas released during this process can cut through the conductive material. Here are some plasma cutting materials you can use in your next project.

Aluminum material

Aluminum material

Aluminum's ability to reflect heat is one of the reasons machinists favor this metal as a plasma cutting material. It is also lightweight, non-corrosive and malleable. In addition, aluminum is cost-effective and plasma cutting time is shorter compared to other materials. Aluminum also has a high recyclability rate, which helps reduce waste in the long run.

Subtype:

Iron piece

Iron piece

Due to its high machinability, steel is one of the most popular metals in machine shops. In addition to machinability, steel also has high tensile strength, ductility and ductility. It is also very durable and beautiful in appearance. One of the main reasons why steel is very suitable for plasma cutting is its high weldability, which allows it to withstand the stress generated by the heat generated by the plasma cutting machine.

Subtypes: 1018, 1020, 1025, 1045, 1215, 4130, 4140, 4340, 5140,A36,ST37

Stainless Steel

Stainless Steel

Stainless steel is a metal alloy that contains at least 11% chromium. The chromium content of this metal gives it a glossy appearance. Due to its strength at high temperatures, this metal is very suitable for plasma cutting because its performance is better than most metals. Stainless steel also has high tensile strength and good plasticity. In addition, stainless steel is easy to process.

Subtypes: 201, 303, 304, 316, 316L, 420, 430, 431, 304

Finishing Options for Plasma Cutting

Parts made using plasma cutting usually have excellent surface treatment results. At Youxinda, we provide a variety of customized finishing options to improve the function, appearance and durability of produced parts.

Name

Product Description

Materials

Color

Texture

Link

anodic oxidation

Anodizing improves corrosion resistance, enhances wear resistance and hardness, and protects the metal surface. Widely used in mechanical parts, aircraft, auto parts, precision instruments, etc.

Aluminum material

Transparent, black, gray, red, blue, gold.

Smooth, matte finish.

Sand blasting

The surface of the parts after sandblasting is smooth and has a matte texture. It is mainly used for vision applications and can be followed by other surface treatments.

ABS, aluminum, brass, stainless steel, steel

Not applicable

Matte

powder coating

A powder coating is a coating that is applied in the form of a free-flowing dry powder. Unlike traditional liquid coatings, which are delivered by evaporation of solvents, powder coatings are typically electrostatically sprayed and then cured under heat or ultraviolet light.

Aluminum, stainless steel, steel

Black, any RAL code or Pantone number

Gloss or semi-gloss

Electroplating

The plating may be functional, decorative or corrosion-related. This process is used by many industries, including the automotive industry, where chrome plating of steel automotive parts is common.

Aluminum, steel, stainless steel

Not applicable

smooth gloss

Polishing

Polishing is the process of creating a smooth and shiny surface through physical friction or chemical interference of parts. This process produces a surface with significant specular reflection, but in some materials can reduce diffuse reflection.

Aluminum, Brass, Stainless Steel, Steel

Not applicable

Smooth

Polishing

Brushing is a surface treatment process in which an abrasive belt is used to draw marks on the surface of a material, usually for aesthetic purposes.

ABS, aluminum, brass, stainless steel, steel

Not applicable

Satin

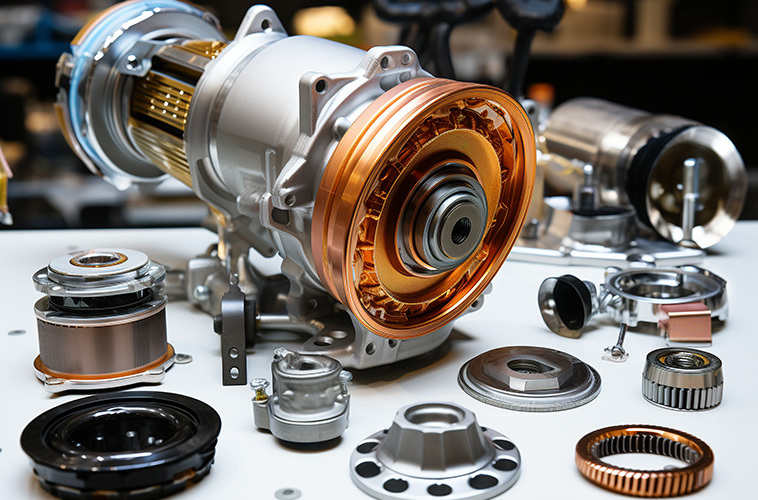

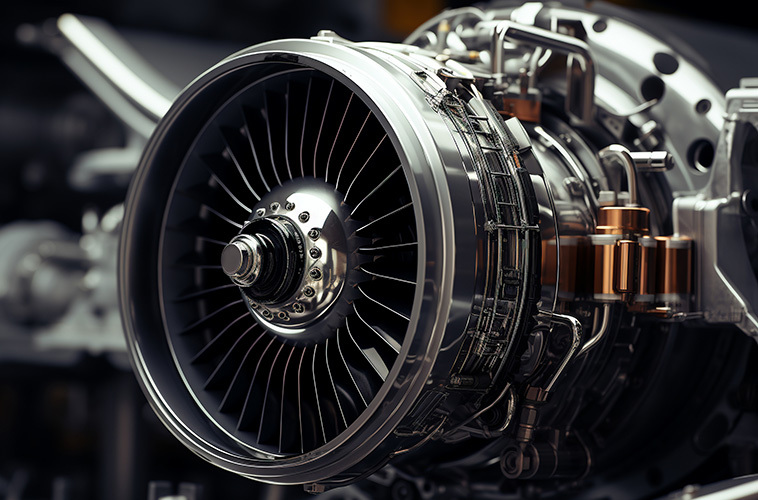

Industrial Application Plasma Cutting

Plasma cutting offers a wide range of benefits for mechanics and the industry-no wonder it has become the process of choice for metal manufacturing. Plasma cutting facilitates the production of prototypes and parts with high precision, regardless of volume. The following is the industrial application of plasma cutting parts by industry.

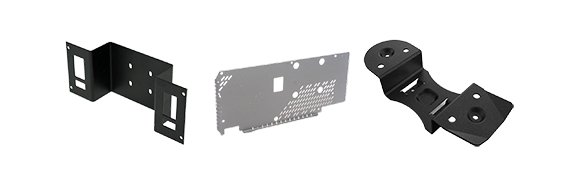

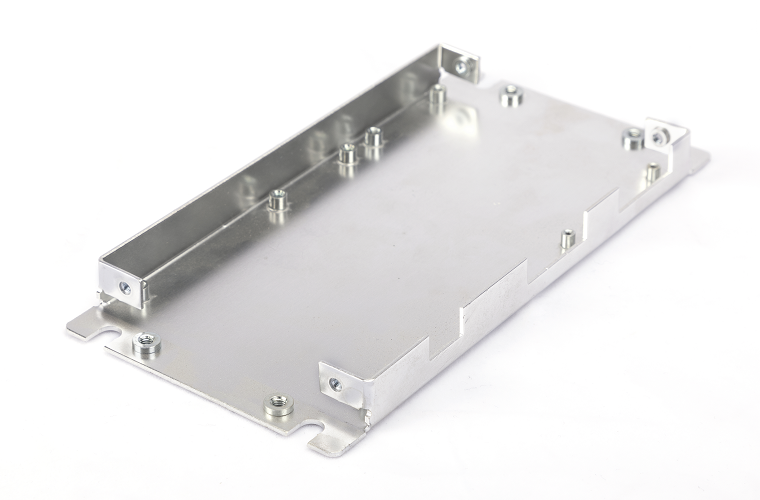

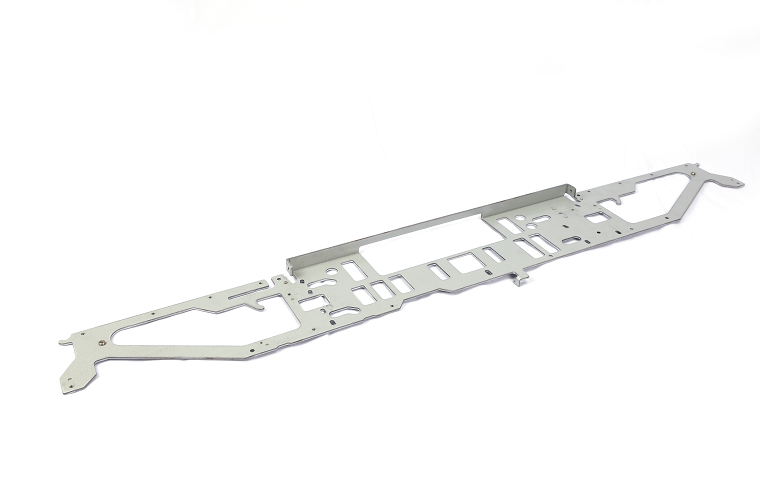

Plasma cutting parts gallery

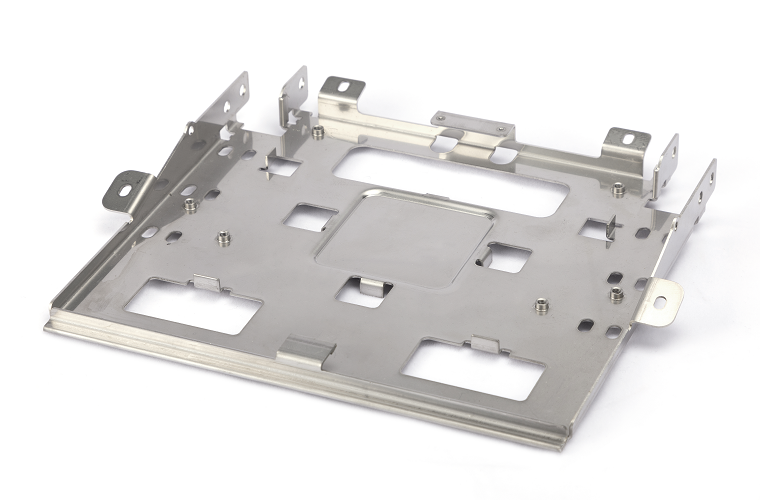

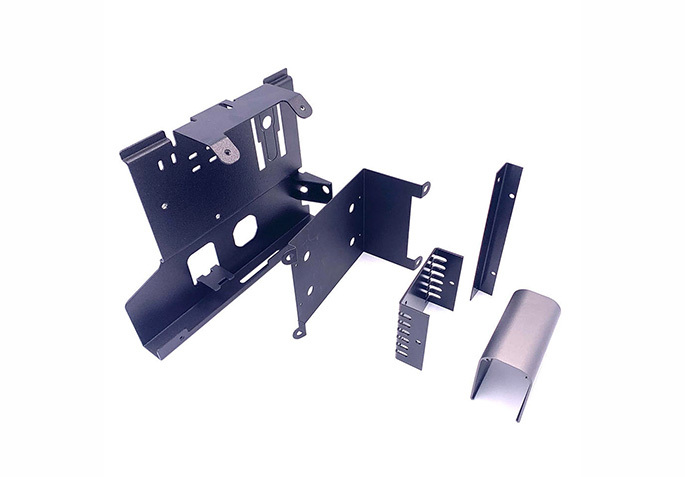

At Yuxingda, we let work speak for us. We produce plasma cut parts for various industries with excellent tolerances, high precision and dimensional stability. Here are some of the plasma cutting projects we are involved in.

Plasma cutting parts library01

Plasma cutting parts library02

Plasma cutting parts library03

Plasma cutting parts library04

Why choose us for plasma cutting

With cutting-edge laser cutting technology and innovative technical expertise, Youxenda is committed to providing the best custom laser cutting services through prototyping and mass production runs. We are a reliable manufacturing company with the appropriate certification and experience to provide cost-effective on-demand laser cutting solutions.

Guaranteed high quality

We have a manufacturing plant certified by ISO 9001:2015, and can provide materials and full-size inspection reports according to your requirements. You can always rest assured that the parts you get from Youxingda will exceed your expectations.

Strong manufacturing capabilities

Our domestic factory in China provides complete project solutions for small and high volume production through flexible materials, surface finish options and unlimited manufacturing capabilities.

Sheet metal engineering support

We offer 24/7 online engineering customer support for your custom engineering and manufacturing problems. This includes case-by-case recommendations to help you reduce costs early in the design phase.