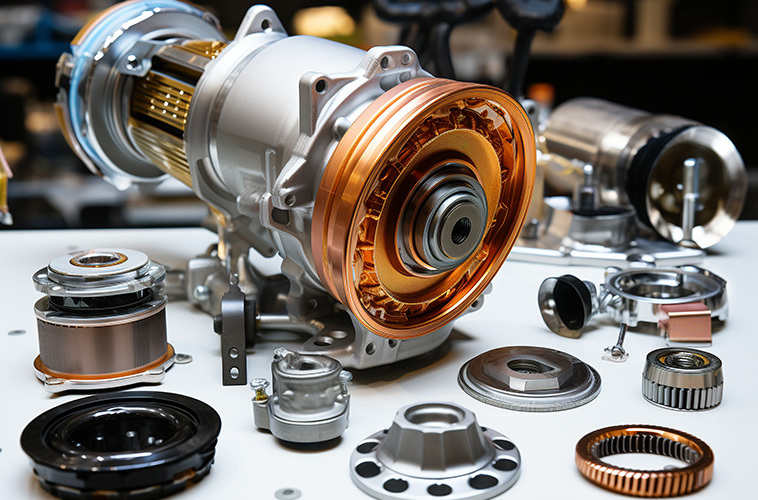

Precision machining services

The tolerance is as low as ± 0.0004 "(0.01mm)

The fastest processing time for parts is 1 day

Why Choose Our Precision Machining Services

Bring your precision CNC machined parts to life with first-class precision machining services. Youxingda has cutting-edge high-precision CNC machining manufacturing capabilities. All prototypes and end-use parts meet strict quality standards and tolerances.

High precision and tight tolerances

Our CNC precision machining combines advanced technology and expertise. As a ISO9001 certified company, we prioritize quality and ensure that components meet specifications

Rapid prototyping and production

We accelerate your product development, from prototyping to production. Our rapid turnaround turns designs into prototypes, enabling faster iterations and shorter time to market. Our CNC machining can be extended to any production volume.

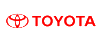

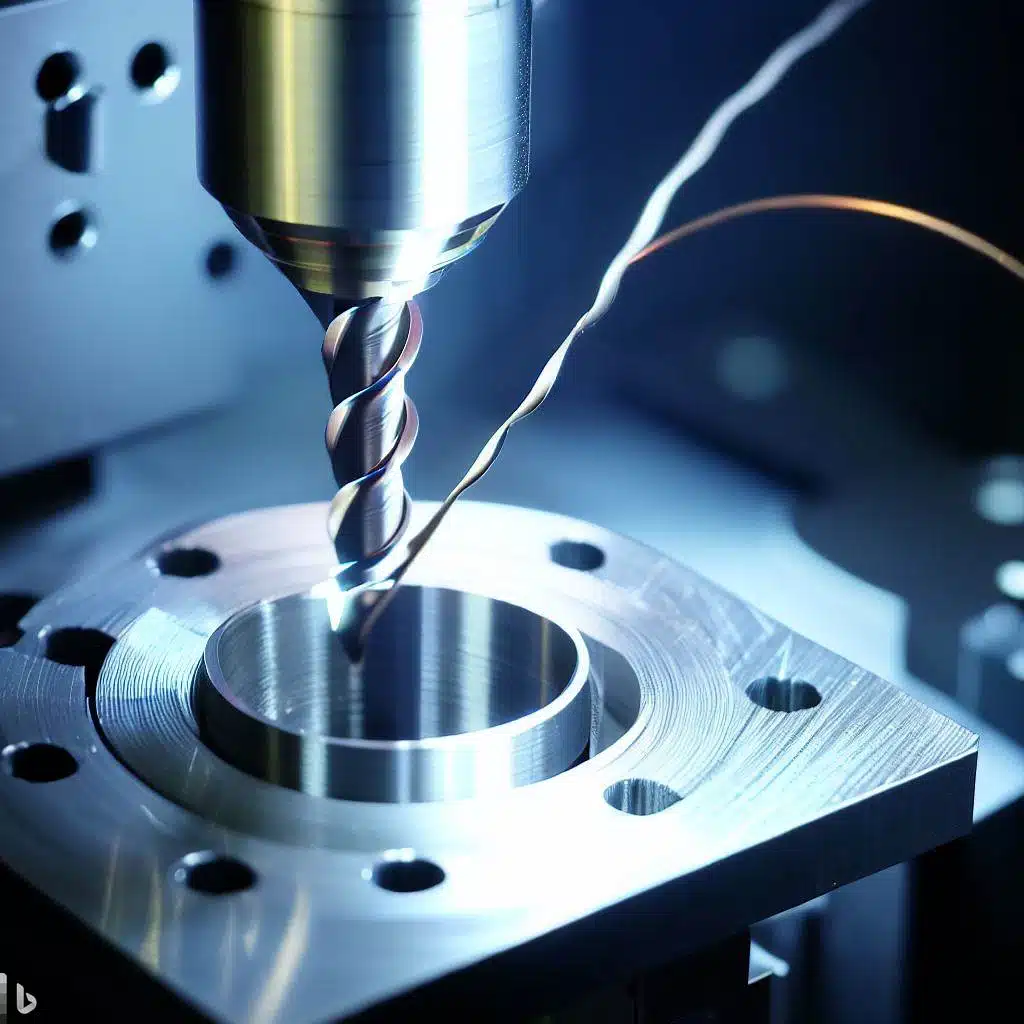

Advanced manufacturing facilities

At Youxinda, our comprehensive equipment includes precision CNC milling, turning and EDM. From prototyping to mass production, we use top materials and technologies. Our professional technicians work tirelessly to achieve the best product quality.

Dedicated customer support

Youxingda has professional engineers ready to optimize your design, reduce costs and improve quality. We trust our team to provide superior advice and unmatched engineering support to ensure best-in-class project results.

Precision CNC machining capability

Wire cutting processing

| ability | Details/Specifications |

| Material compatibility | Stainless steel, titanium, aluminum, tool steel, copper |

| tolerance | ± 0.0001" (0.0025 mm) or better (based on material and thickness) |

| Maximum workpiece size | Length: 16" (400mm)

Width: 12 mm (300 inches) Height: 8 mm (200 inches) |

| Cutting speed | Up to 300 mm2/min (depending on material and thickness) |

| Surface treatment | as fine as Ra 0.2 μm |

| Maximum cutting thickness | Up to 12 inches (300 mm) – varies depending on material |

| Wire size range | 0.004 in (0.1 mm) to 0.012 in (0.3 mm) |

Mirror EDM machining

| ability | Details/Specifications |

| Material compatibility | Stainless steel, titanium, aluminum, tool steel, copper |

| Surface treatment | Achievable down to Ra 0.05 μm or better (based on material and process parameters) |

| tolerance | ± 0.00005" (0.0013 mm) or better (depending on material and thickness) |

| Maximum workpiece size | Length: 16" (400mm)

Width: 12 mm (300 inches) Height: 8 mm (200 inches) |

| Maximum cutting thickness | Up to 10 inches (250 mm) – varies depending on material |

Grind

| ability | Details/Specifications |

| Material compatibility | Stainless steel, aluminum, tool steel, copper, ceramic, carbide |

| Grinding method | Surface grinding, cylindrical grinding, centerless grinding, internal grinding |

| tolerance | ± 0.0001" (0.0025 mm) or better (depending on material and grinding method) |

| Maximum workpiece size | Length: 24" (600mm)

Width: 10 mm (250 inches) Diameter: 8" (200 mm) for cylindrical grinding |

| Surface treatment | Achievable as low as Ra 0.1 μm or better (based on material and grinding method) |

CNC turning

| ability | Details/Specifications |

| Material compatibility | Stainless steel, aluminum, tool steel, copper, brass, titanium, plastic |

| Turning operations | External and internal turning, face turning, taper turning, boring, drilling, threading |

| tolerance | ± 0.0005" (0.0127 mm) or better (depending on material and operation) |

| Maximum workpiece diameter | 20" (508 mm) or machine capability-specific |

| Maximum workpiece length | 60" (1524 mm) or machine capable-specific |

| axis | 2-, 3-, multi-axis turning capabilities |

| Bar feed diameter | Up to 3" (76 mm) or machine specific |

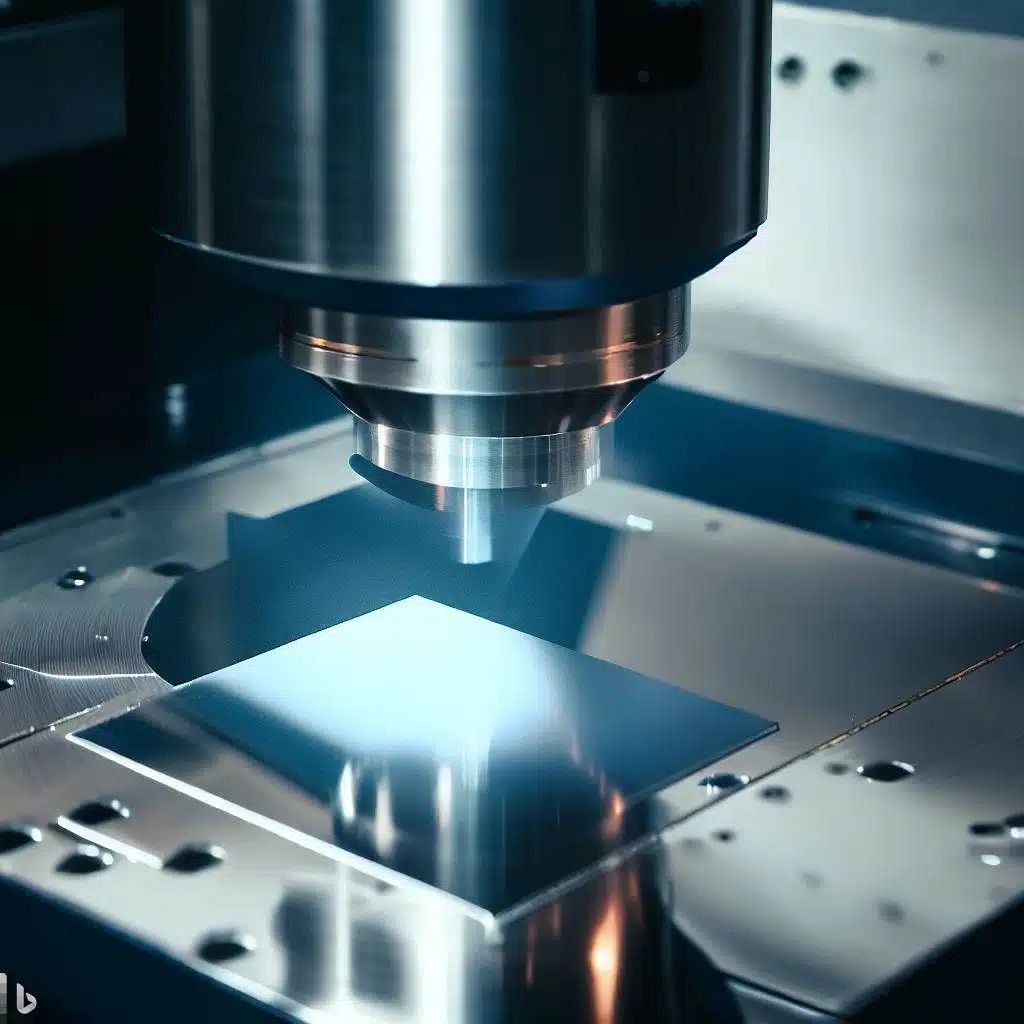

CNC milling machine

| ability | Details/Specifications |

| Material compatibility | Stainless steel, aluminum, tool steel, copper, brass, titanium, plastic |

| Grinding operation | Face milling, copy milling, pocket milling, complex surface milling, drilling, boring |

| tolerance | ± 0.0005" (0.0127 mm) or better (depending on material and operation) |

| Maximum workpiece size | X: 40" (1016 mm)

Y: 20" (508 mm) Z: 25" (635 mm) or machine capacity-specific |

| axis | 2-, 3-, multi-axis turning capabilities |

| Bar feed diameter | Up to 3" (76 mm) or machine specific |

Precision machining for prototyping and production

Accelerate your product development and deliver with maximum efficiency with custom machined prototypes and end-use products from Youxenda. Customize your production needs by choosing the manufacturing volume and process that exactly meets your requirements. We guarantee fast turnaround times without compromising the quality of prototypes and production parts.

Rapid prototyping

Utilize our strong manufacturing capabilities to deliver prototypes quickly and with high quality. Using the latest technology, we ensure fast and accurate production, accelerating your time from testing to market launch.

Small batch manufacturing

Our precision machining is suitable for small batch production, providing fast delivery and unparalleled accuracy. We ensure that your project meets high-quality standards with reduced costs.

Mass production

Youxingda is capable of handling large-scale production orders. This means they can efficiently produce a large number of precision machined parts without affecting quality or accuracy.

Standard for Dimensions of Precision Machined Parts

Classification

Minimum size (mm)

Maximum size (mm)

Common Applications

Ultra-precision parts

0.1

1

Watch parts, micro devices

micro-machined parts

1.1

10

Medical devices, small electronic products

Small machine machining parts

10.1

50

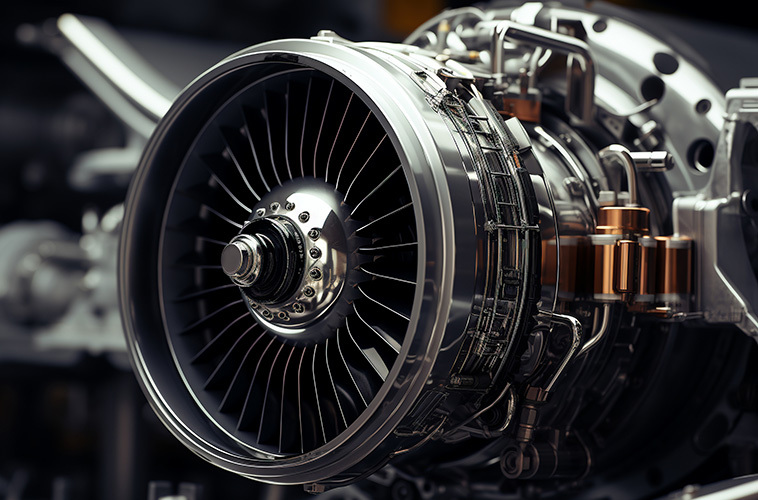

Aerospace, Automotive Sensors

Medium machined parts

50.1

200

Automotive, Defense, Industrial Tools

mainframe machining parts

200.1

1000

Heavy machinery, construction

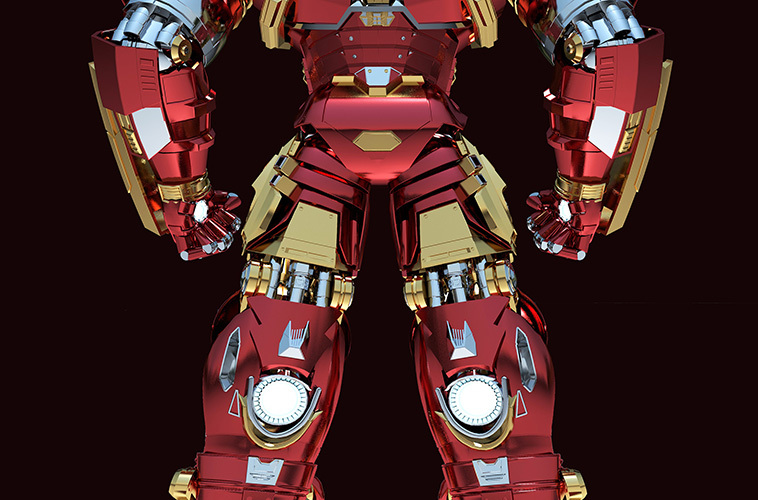

Material for custom CNC machining parts

At Youxingda, we offer a wide range of materials to meet the different needs of our customers. Our commitment to excellence ensures that every custom CNC machined part we produce is of unparalleled quality and precision. Whether you need metal parts with excellent strength or plastic parts with excellent mechanical properties, our material selection can meet the needs of various industries and applications.

Metal Products

Metal Products

Aluminum is a very ductile metal, so it is easy to process. The material has a good strength-to-weight ratio, and there are many types to choose from, suitable for various applications.

Price: $

Delivery time: <10 days

Tolerance: ± 0.005mm (± 0.0002 inches)

Maximum part size: 600 x 600 x 200 MM

Plastic

Plastic

Copper has excellent thermal conductivity, electrical conductivity and plasticity. It also has high ductility, corrosion resistance and is easy to weld.

Price: $$$

Delivery time: <10 days

Chamber wall thickness: 0.75mm

Tolerance: ± 0.005mm (± 0.0002 inches)

Maximum part size: 600 x 600 x 200 MM

Surface treatment of precision CNC machining

At Youxinda, we prioritize the aesthetics and functionality of precision CNC parts. Our diverse surface treatments ensure custom precision. Believe that we are committed to enhancing your projects with lasting excellence.

Processing completed

anodic oxidation

Bead spray

powder coating

Polishing

Electroplating

passivation

Bead spray

We are suitable for precision machining parts for various industrial applications

Youxenda works with top industry manufacturers to streamline the supply chain through digital custom precision CNC machining, effectively turning ideas into tangible products.