Rapid prototyping and on-demand production

The automotive industry

The tolerance is as low as ± 0.0004 "(0.01mm)

ISO 9001:2015 certification

24/7 Engineering Support

Why choose us for car manufacturing

At Youxinda, we specialize in the prototyping and production of industry standard automotive parts. We combine manufacturing and engineering expertise with advanced technology to ensure that we can provide high-quality parts regardless of complexity. We also guarantee that parts will stand the test of time, while ensuring that you meet production goals and accelerate your automotive product development.

Strong production capacity

With our advanced technology and machines, our automotive product manufacturing capabilities can ensure that each auto part has high quality and correct size specifications, while performing well.

ISO certification

Youxingda is an ISO 9001 certified manufacturing company. Regardless of the complexity of the design, we can ensure that you always get high-quality auto parts. In addition, we guarantee that we use internationally recognized best practices to develop your product and that it meets all required standards.

Fully customizable

Considering the size, material and surface finish you need, we will operate according to the specifications of how you want to produce the parts. We believe that developing custom products can make your product unique and put you ahead of the competition.

Rapid Cycle

With our instant quotation system, coupled with the perfect combination of advanced technology and top talents, Youxenda produces and delivers your auto parts at the fastest speed. Making your products faster will provide greater flexibility to improve or iterate on them, thereby outperforming your competitors in the rapid changes in the market.

Why choose us for car manufacturing

Obtain reliable solutions for new product development in the automotive industry. Our custom automotive parts are professionally designed to meet and exceed industry standards for durability and performance. Our solutions span different stages of production to meet your manufacturing goals.

Model

Model

The prototype marks an early stage in the development of automotive products. At this stage, you will test your design, make design changes if necessary, and choose the right material for your car parts.

Model

At Youxinda, we create a working prototype for you using your design files and product requirements for automotive prototyping. According to your design needs, we will develop parts that are exactly the same in appearance and function as the final product. Our goal is to allow you to inspect and test the part to make sure it meets your specifications. We also guarantee a quick turnaround of prototypes.

Quickly apply changes to materials and designs at low cost

Prototypes with complex geometries are also presented in detail

Create the same model as the final product

Engineering Verification and Testing (EVT)

Engineering Verification and Testing (EVT)

Quickly and efficiently perform performance-based iterations to ensure prototype functionality meets standard requirements.

Engineering Verification and Testing (EVT)

At Youxinda, we make functional prototypes, making it easier to identify and avoid design risks. While this process usually requires multiple design iterations, it ensures that the final production prototype meets all functional and performance requirements.

24/7 Design and Engineering Support

Precision parts manufacturing

Material property optimization for custom design

Design Verification and Testing (DVT)

Design Verification and Testing (DVT)

This phase involves evaluating and verifying part function, appearance and performance using different materials and surface treatment options. In other words, this test helps ensure that the part meets your specific design and product requirements.

EVT

At Youxinda, we offer a wide range of materials and surface treatment options to meet your unique design requirements. Parts with beautiful finishes at this stage always have end-use functionality and are ready for market testing.

Long-lasting and high-quality surface treatment

Appearance performance evaluation and verification

Consumer evaluation and market testing of first-class parts

Production Verification and Testing (PVT)

Production Verification and Testing (PVT)

This is the final stage before mass production begins. PVT involves preparing designs for full-scale production using advanced quality control and production-grade manufacturing capabilities.

PVT

At Youxinda, we create a working prototype for you using your design files and product requirements for automotive prototyping. According to your design needs, we will develop parts that are exactly the same in appearance and function as the final product. Our goal is to allow you to inspect and test the part to make sure it meets your specifications. We also guarantee a quick turnaround of prototypes.

Verify the manufacturing process

Small batch production tools

Rapid delivery of production quality components

Evaluate the capabilities of production-ready parts

Mass production (MP)

Mass production (MP)

This is the next stage after product testing and involves mass production of end-use components. At this stage, the fast delivery of the final product and the accuracy of the quality requirements are the key.

MP

At Youxinda, we create a working prototype for you using your design files and product requirements for automotive prototyping. According to your design needs, we will develop parts that are exactly the same in appearance and function as the final product. Our goal is to allow you to inspect and test the part to make sure it meets your specifications. We also guarantee a quick turnaround of prototypes.

meticulous inspection of quality control

Quality custom parts

Secondary operation for optimal surface requirements

Precision machined parts always meet strict tolerance requirements

Trusted by Fortune 500 companies

vehicle factory

Auto Parts Company

Electric Vehicle

Business Vehicle

Multi-purpose vehicle

Electric bicycles and scooters

automobile manufacturing capacity

We provide the highest quality service at different stages of the production cycle, from prototyping to mass production. At Youxingda, we guarantee to provide you with high-quality auto parts for roads. In addition, our quality control process can ensure that you can obtain parts that meet quality requirements at low cost.

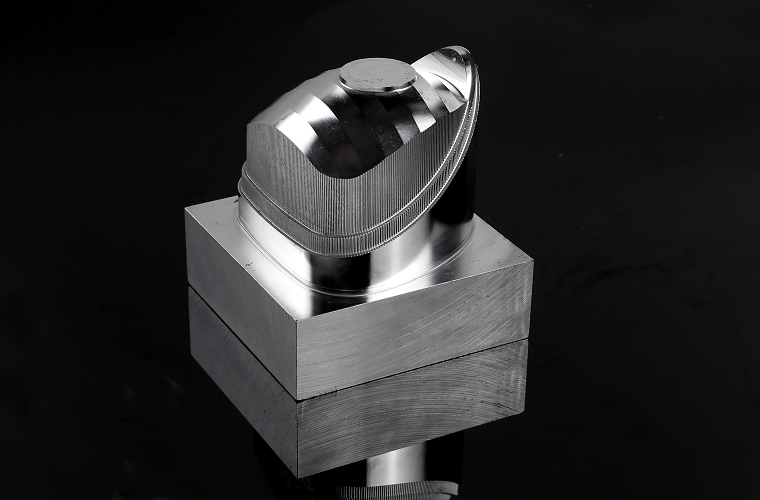

CNC machining

Injection molding

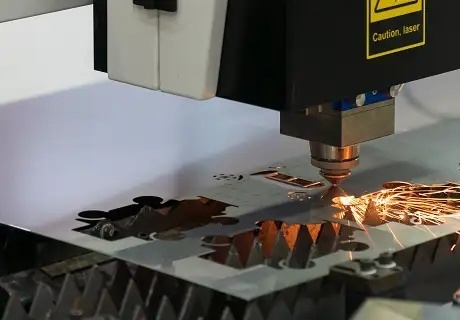

Sheet metal processing

3D printing

Materials for Automotive Product Development

Product requirements determine the right material. However, don't worry, we have a long list of production-grade materials, including metals and composites, which are very suitable for the automotive industry. Here are some of these materials.

Aluminum material

Aluminum material

Aluminum has an excellent strength-to-weight ratio and is well suited for the production of lightweight automotive parts. Such metals have a variety of beneficial properties, including stiffness, corrosion resistance, ductility, and high machinability. Aluminum is an ideal material for making engine blocks, intake manifolds, lights, wheels, cylinder heads, etc.

Price: $

Delivery time: <10 days

Tolerance: ± 0.125mm (± 0.005 inches)

Maximum part size: 200 x 80 x 100 cm

Titanium

Titanium

Titanium is another metal that is widely used in the automotive industry. This metal has excellent chemical and corrosion resistance. It also has an excellent strength-to-weight ratio and resistance to extreme temperatures. Titanium is used in automotive brake calipers, tire rims, engine valves and other mechanical parts.

Price: $$$

Delivery time: <10 days

Chamber wall thickness: 0.75mm

Tolerance: ± 0.125mm (± 0.005 inches)

Maximum part size: 200 x 80 x 100 cm

Stainless Steel

Stainless Steel

Stainless steel is a mild steel with properties sought after in many industrial applications. Stainless steel typically contains at least 10% chromium (by weight).

Price: $$

Delivery time: <10 days

Chamber wall thickness: 0.75mm

Tolerance: ± 0.125mm (± 0.005 inches)

Maximum part size: 200 x 80 x 100 cm

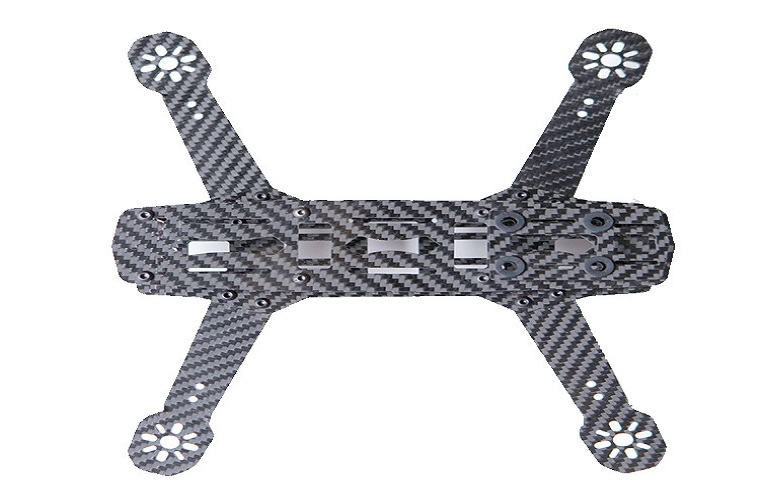

carbon fiber

carbon fiber

Carbon fiber reinforced polymers are widely used in the aerospace industry due to their high specific strength and stiffness. They also have higher fatigue and corrosion resistance, making them useful for structural components such as wing boxes, airframes and control surfaces.

liquid silicone rubber

Titanium

Our liquid silicon material is an excellent choice for thermal stability and flexibility. They thrive in the extreme environments of the aerospace industry to ensure oil and fuel resistance.

Auto parts post-processing

Get high-quality surface treatment for your car parts to improve functionality and product aesthetics. Various surface treatments help to improve the corrosion resistance and wear resistance of the product.

Name

Product Description

Materials

Color

Texture

Link

anodic oxidation

Anodizing improves corrosion resistance, enhances wear resistance and hardness, and protects the metal surface. Widely used in mechanical parts, aircraft, auto parts, precision instruments, etc.

Aluminum material

Transparent, black, gray, red, blue, gold

Smooth, matte finish

powder coating

A powder coating is a coating that is applied in the form of a free-flowing dry powder. Unlike traditional liquid coatings, which are delivered by evaporation of solvents, powder coatings are typically electrostatically sprayed and then cured under heat or ultraviolet light.

Aluminum, stainless steel, steel

Black, any RAL code or Pantone number

Gloss or semi-gloss

Electroplating

The plating may be functional, decorative or corrosion-related. This process is used by many industries, including the automotive industry, where chrome plating of steel automotive parts is common.

Aluminum, stainless steel, steel

Not applicable

smooth gloss

Bead spray

The pearlescent treatment makes the material look smoother, shinier and cleaner. It has been used on a wider range of materials, including metal, plastic, rubber and glass.

Aluminum, stainless steel, thermoplastics

Gray, black

Smooth, Matte

passivation

Passivation helps reduce corrosion, oxidation and mild chemical attack on stainless steel. It also helps to enhance the beauty of this metal.

Stainless steel, aluminum, titanium

Yellow, transparent blue, green, black

Smooth, matte, semi-gloss

Heat treatment

Heat treatment makes it easier to weld parts and improves the mechanical properties, strength and flexibility of the material. It can also improve brittleness and wear resistance.

Titanium, aluminum, stainless steel

Light yellow, brown, straw

Smooth, Matte

Applications in the automotive field

At Youxingda, we have increased the productivity of various auto parts. Common automotive applications we undertake include.

Lighting function and lens

Aftermarket Parts

Schedule

Enclosure and Housing

armature

Pipeline Components

Support for automotive consumer electronics

Plastic Instrument Panel Assembly

Custom prototypes and parts for automotive companies

Businesses and auto parts companies trust our manufacturing solutions to produce their custom auto parts. They rely on us at all stages of production, from prototyping to mass production, because they know that the parts we produce meet industry performance and safety standards. Below is our gallery, which shows precision-machined car prototypes and mass-produced parts.