5-axis CNC machining

The tolerance is as low as ± 0.0004 "(0.01mm)

10s

Instant Quote

1 day

Delivery time

0 PC

Minimum order quantity

0.010 mm

Tolerance

5-axis CNC machining capability

From the basics of 3-axis to complex 5-axis projects, our precision CNC milling brings your designs to life with unparalleled precision and craftsmanship.

3+2-axis CNC machining

Utilize the best 3+2 axis machining technology for your unique application. This process fixes the parts in a specific direction to allow for the usual 3-axis machining process. Our 3+2 axis machining uses shorter and more robust cutting tools to provide better dimensional stability for your parts. Obtain complex CNC machined parts with strict tolerances at lower costs and cycle times.

Synchronous 5-axis CNC machining

Fast, effective, and continuous 5-axis CNC machining with improved transition and surface quality. Here, we use a five axis machining center that can continuously adjust the motion of all five axes without interruption. Our 5-axis CNC machining has intelligent functions that ensure efficient continuous processes and transitions.

From CNC prototyping to production

CNC machining is a computerized, versatile manufacturing process that is well suited for rapid prototyping and on-demand production. There are custom CNC services available at YXD.

Rapid prototyping

With our instant quote platform and powerful capabilities, you can get exceptional prototypes in a very short lead time. This allows you to quickly test prototype parts and bring them to market.

Bridge making

The transition to production is critical to closing the gap between part design and actual product launch. Don't worry about it. Our professional engineering team is ready to provide practical design advice for your small batch machined parts.

On-demand production

Our full service for on-demand production orders ensures that you get quality products with high precision and high standards. Increased productivity also allows for timely delivery of production parts.

5-axis CNC machining tolerances

Our ISO 9001 certification indicates that we manufacture 5-axis milled parts to meet the strictest tolerances. Our standard tolerances for CNC milling plastics are ISO-2768-m and metal ISO-2768-f. Obtain high-quality and precise complex parts with first-class dimensional stability.

imperial units

Metric units

imperial units

Maximum part size

600X600X200mm

23.6 × 23.6 × 7.8 inches

Minimum part size

2X2X2mm

0.1 × 0.1 × 0.1 inches

Minimum feature size

Φ0.50mm

Φ 0.00197 inches

Standard tolerance

Metal: ISO 2768-f

Plastic: ISO 2768-m

Linear Dimensions

/- 0.005mm

/- 0.0002 inches

Bore diameter (unreamed

/- 0.005mm

/- 0.0002 inches

Shaft diameter

/- 0.005mm

/- 0.0002 inches

edge condition

The sharp corners will be removed in the form of a chamfer or radius. The dimensions of the chamfer or the resulting radius must be indicated on the drawing.

Threads and threaded holes

Standard size: diameter: standard bit size; depth: 4 x diameter

Maximum size: diameter: Φ1mm; depth: 10 × diameter

YXD can produce any specifications and sizes of threads required by customers

Text

For plastic and soft materials: a minimum width of 0.018 inches and a depth of 0.011 inches

For hard materials: a minimum width of 0.033 inches and a depth of 0.011 inches

For plastic and soft materials: a minimum width of 0.018 inches and a depth of 0.011 inches

For hard materials: a minimum width of 0.033 inches and a depth of 0.011 inches

Threads and threaded holes

For plastic and soft materials: a minimum width of 0.018 inches and a depth of 0.011 inches

For hard materials: a minimum width of 0.033 inches and a depth of 0.011 inches

Standard text can be created using CNC engraving or laser engraving according to customer's requirements.

Delivery time

5 working days with less than 10 parts

Customized 5 axis CNC machining material

Our 5-axis milling service is compatible with a wide range of materials from metal to plastic. Depending on your application, you can choose from more than 50 production-grade materials we offer at YXD. See our list of 5-axis CNC machining materials. You can also contact us to discuss your unique requirements.

Aluminum material

Aluminum material

Aluminum is a very ductile metal, so it is easy to process. The material has a good strength-to-weight ratio, and there are many types to choose from, suitable for various applications.

Price: $

Delivery time: <10 days

Tolerance: ± 0.005mm (± 0.0002 inches)

Maximum part size: 600 x 600 x 200 MM

Copper

Copper

Copper has excellent thermal conductivity, electrical conductivity and plasticity. It also has high ductility, corrosion resistance and is easy to weld.

Price: $$$

Delivery time: <10 days

Chamber wall thickness: 0.75mm

Tolerance: ± 0.005mm (± 0.0002 inches)

Maximum part size: 600 x 600 x 200 MM

Stainless Steel

Stainless Steel

Stainless steel is a mild steel with properties sought after in many industrial applications. Stainless steel typically contains at least 10% chromium (by weight).

Price: $$

Delivery time: <10 days

Chamber wall thickness: 0.75mm

Tolerance: ± 0.005mm (± 0.0002 inches)

Maximum part size: 600 x 600 x 200 MM

Titanium

Titanium

Titanium has many material properties that make it an ideal metal for demanding applications. These properties include excellent corrosion resistance, chemical resistance and resistance to extreme temperatures. The metal also has an excellent strength-to-weight ratio.

Price: $$$

Delivery time: <10 days

Chamber wall thickness: 0.75mm

Tolerance: ± 0.005mm (± 0.0002 inches)

Maximum part size: 600 x 600 x 200 MM

Plastic

Plastic

Plastic is also a very popular choice for CNC machining because of its wide range of options, relatively low price, and significantly faster processing time required. We supply all common plastics for CNC machining services.

Surface treatment for 5-axis CNC machining

Youxenda provides a large number of available surface treatments that can improve the surface quality of 5-axis machined parts. The application of these finishes helps to improve the appearance, surface roughness, hardness, corrosion resistance, etc. of the part. They also hide visible tool marks on the surface of the product.

Name

Product Description

Materials

Color

Texture

Link

anodic oxidation

Anodizing improves corrosion resistance, enhances wear resistance and hardness, and protects the metal surface. Widely used in mechanical parts, aircraft, auto parts, precision instruments, etc.

Aluminum material

Transparent, black, gray, red, blue, gold

Smooth, matte finish

Sand blasting

The surface of the parts after sandblasting is smooth and has a matte texture. Primarily for vision applications, other surface treatments can follow.

ABS, aluminum, brass, stainless steel, steel

Not applicable

Matte

powder coating

A powder coating is a coating that is applied in the form of a free-flowing dry powder. Unlike traditional liquid coatings, which are delivered by evaporation of solvents, powder coatings are typically electrostatically sprayed and then cured under heat or ultraviolet light.

Aluminum, stainless steel, steel

Black, any RAL code or Pantone number

Gloss or semi-gloss

Electroplating

The plating may be functional, decorative or corrosion-related. This process is used by many industries, including the automotive industry, where chrome plating of steel automotive parts is common.

Aluminum, steel, stainless steel

Not applicable

smooth gloss

Polishing

Polishing is the process of creating a smooth and shiny surface through physical friction or chemical interference of parts. This process produces a surface with significant specular reflection, but in some materials can reduce diffuse reflection.

Aluminum, Brass, Stainless Steel, Steel

Not applicable

Smooth

Polishing

Brushing is a surface treatment process in which an abrasive belt is used to draw marks on the surface of a material, usually for aesthetic purposes.

ABS, aluminum, brass, stainless steel, steel

Not applicable

Smooth

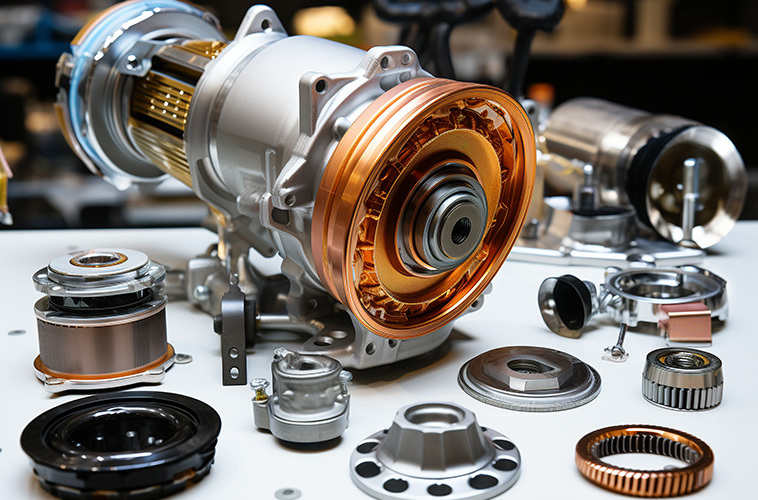

5-axis CNC machining equipment

Youxingda implements strict quality control protocols to ensure that every customer receives quality products. We have specialized workshops equipped with state-of-the-art equipment for various operations. In this way, we have carried out meticulous inspection in the 5-axis CNC machining process.

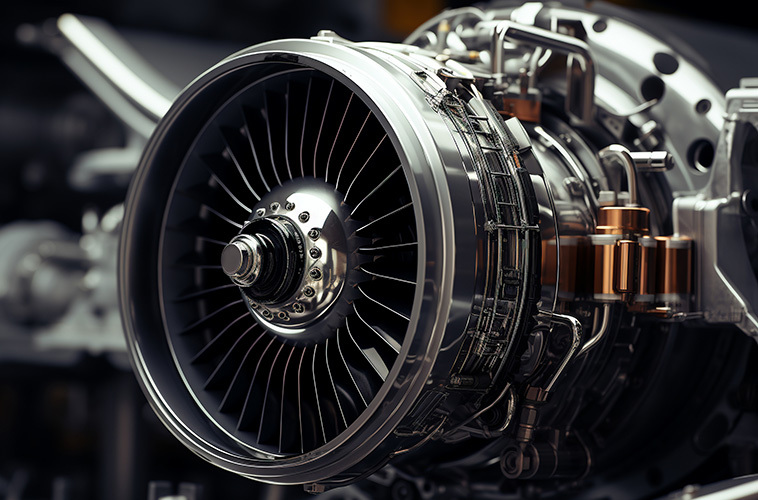

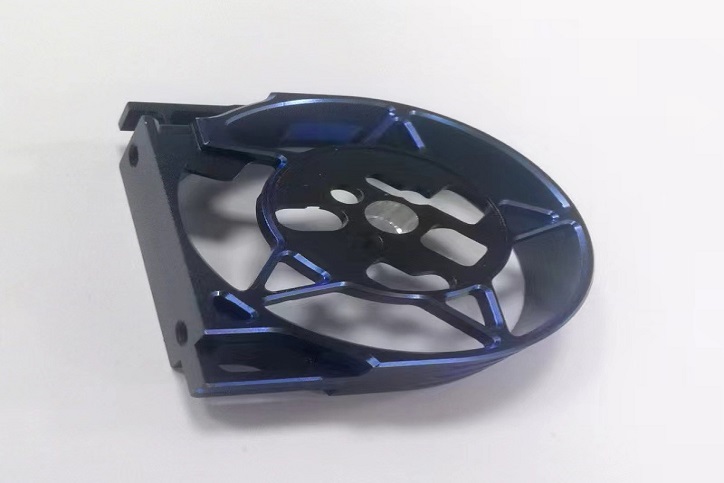

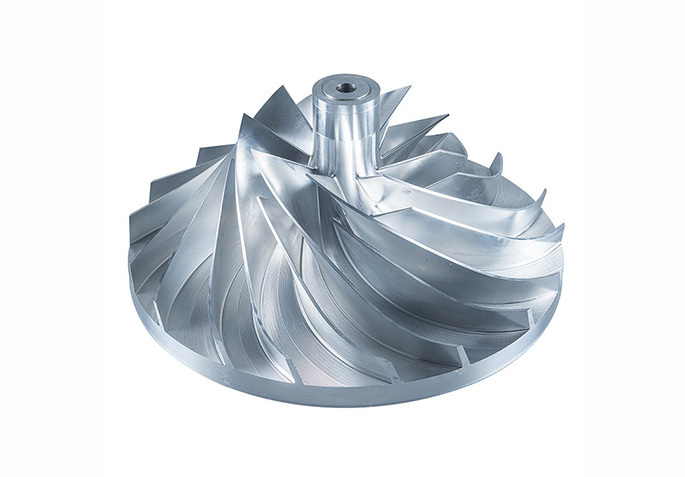

Application of five-axis milling

Our 5-axis milling service is the best choice for manufacturing complex, high-precision components for a variety of industries. Our manufacturing capabilities allow us to accelerate the production of several components, including:

Auto parts: engine housing, light guide, valve, engine cover, inspection fixture

Aerospace components: fuselage sections, bulkheads, landing gear components

Medical and surgical tools: forceps, scalpels, spacers, clamps, knives, surgical scissors

Military parts: submarine parts, turbine blades, engine parts, weapons, sensors

Military parts: submarine parts, turbine blades, engine parts, weapons, sensors

CNC machine processing parts gallery

CNC machining part library 01

CNC machining part library 02

CNC machining part library 03

CNC machining part library 04

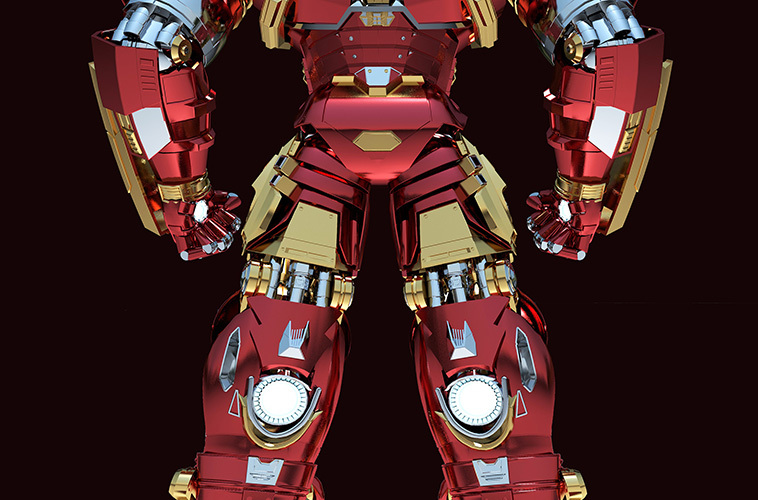

Visit our 5-axis machining workshop

Check out our incredible range of well-functioning 5-axis machining centers, from the best 5-axis horizontal machining centers to top-notch vertical machining centers. These are the ideal facilities to manufacture components for a wide range of industries. We combine advanced technology with skilled technicians to provide results that perfectly meet your needs.

Why Choose Our 5-Axis CNC Machining Service

At Youxingda, we combine first-class precision machining with outstanding customer service. Enjoy our reliable 5-axis machining services to advance your project. Our experienced and skilled mechanics use state-of-the-art milling machines to deliver highly accurate components, regardless of complexity.

Fast production speed

We manufacture prototypes with high precision and produce parts in small batches. Our CNC 5-axis milling service achieves standard tolerances of/- 0.02mm. However, we can also achieve tighter tolerances up to/- 0.01mm.

Handling complex designs

Experience unparalleled precision in every task. Our advanced milling processes ensure that components adhere to tight tolerances, accurate to ± 0.01mm, for seamless assembly and operational excellence.

Fast production speed

We have a machine shop equipped with a 5-axis machining center. This ability helps us to create prototypes and produce parts in small batches in a matter of days. Our synchronous 5-axis machining allows uninterrupted continuous machining, thus ensuring faster production.

Smooth finish

The 5-axis machining process provides a high quality machined surface finish. In addition, the process is compatible with various surface treatments. We can perform surface treatment on your 5-axis machined parts, such as electroplating, polishing, sandblasting, etc. These surface treatments provide better surface quality and mechanical properties for the machined parts.

We use 5-axis CNC machining for various industrial applications

Youxingda partners with leading manufacturers from different industries to support growing demand and streamline their supply chain. Our digital custom CNC machining services help more and more manufacturers to put their method into products