High Quality Customized EDM Machining parts

Our main products are yoga series, outdoor leisure series, sewing products series, plastic accessories series. We are professional manufacturer of EVA foam roller, PE foam roller, ankle weight, sports belt, massage bar, hula hoop, dumbbell and kettlebell.

Key words:

DiVona

Detailed

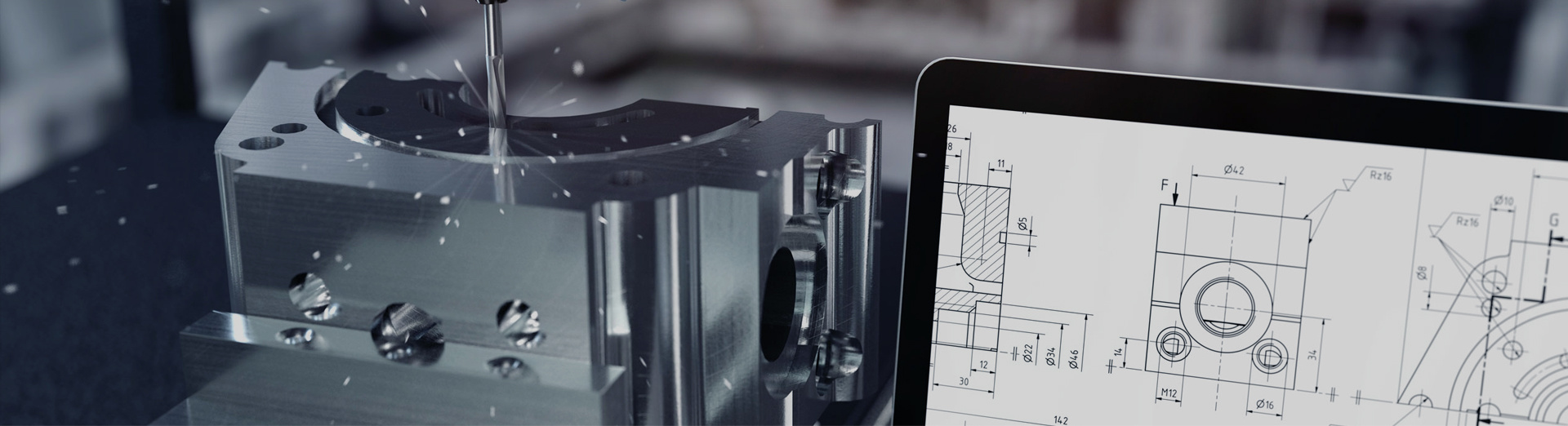

At Youxinda, our CNC milling services offer a wide range of materials to ensure precision and durability. This wide selection enables our customers to provide the choice for their projects, thereby improving the quality and performance of their products.

On demand CNC milling services for rapid prototyping and production parts. Obtain customized milling parts made of various high-quality metals and plastics.

Instant CNC quotation and free DFM

A strict tolerance of 0.01 millimeters

The fastest milling time for parts is 1 day

3. 4. 5-axis milling

High Quality Customized EDM Machining parts

The EDM Process is commonly used in the Tool and Die industry for mold-making, however in recent years EDMhas become a integral part for making prototype and production parts.

Product Description

| Product Name | EDM machining Parts |

| Quality control | 100% QC quality inspection before delivery, can provide quality inspection form |

| Product Size | Customized Size |

| Product Color | Customized Color |

| Material | Conductive material |

| Surface Treatment | Painting,Electroplating,Coating, Polishing,Anodizing |

| MOQ | Accept small order,please feel free to contact us for further inquiry |

| Service | We will answer your email or inquiry within 12 hours. |

| Packing |

lnner packaging:PP bag,bubble bag, plastic wrap, foam etc. Outer packaging:strong carbon box, wooden case, pallet etc |

| Delivery | DHL, FEDEX, UPS, TNT, EMS, by air ,by sea or according to customers' requirement |

| Application | Automotive, Automation, Test systems, Sensors, Medical,Sports,Consumer, Home appliance,Electronic , Pumps, Computers, Power and energy, Architecture, Printing, Food, Textilemachinery,Optical,Lighting, Security and safety, AOl, SMT equipment, etc. |

Electrical discharge machining (EDM) is a machining method primarily used for hard metals or those that would be impossible to machine with traditional techniques. One critical limitation, however, is that it only works with materials that are electrically conductive. This method is especially well-suited for cutting intricate contours or delicate cavities that would be difficult to produce with a grinder, an end mill or other cutting tools. Metals that can be machined with EDM include hastalloy, hardened tool-steel, titanium, carbide, inconel and kovar.

This method is sometimes called “spark machining” because it removes metal by producing a rapid series of repetitive electrical discharges. These discharges are passed between an electrode and the piece of metal being machined. The small amount of material that is removed from the workpiece is flushed away with a continuously flowing fluid. The repetitive discharges create a set of successively deeper craters in the work piece until the final shape is produced.

Wire EDM Machining (also known as Spark EDM) is an electro thermal production process in which a thin single-strand metal wire (usually brass) in conjunction with de-ionized water (used to conduct electricity) allows the wire to cut through metal by the use of heat from electrical sparks. Due to the inherent properties of the process, wire EDM can easily machine complex parts and precision components out of hard conductive materials.

Application

1. lt is widely used in processing various punching dies.

2. Can process micro-shaped holes, narrow slits and workpieces with complex shapes.

3. Machining templates and forming tools.

4. Processing powder metallurgy molds, inlaid cavity molds, wire drawing molds, corrugated plate forming molds

5. Machining hard materials, cutting thin slices, cutting precious metal materials

6. Machining cams, special gears.

7. lt is suitable for the processing of small batches and multi-variety parts, reducing the cost of mold making and shortening the production cycle.

8. t can be used to process material test samples, various types of holes, and other complex shape parts and parts of high hardness materials.

9. lt can process microstructures, special-shaped grooves and standard defects

10. When trial-producing new products, parts can be cut directly from the blank

11. When processing thin parts, multiple pieces can be stacked together for processing.

YXD Company is ISO9001:2015 certified enterprise, specializing in the design and manufacture of various non-standard machining parts. We have 20 years manufacturing experience and machining services, 3/4/5 axis CNC machining services, CNC turning services, CNC turn-milling services ,3D printing services ,Vacuum Casting services,EDM Merchining services and other machining services.

We introduces CNC machining center, CNC compound turning and milling machine tools, computer numerical control lathes, high-precision automatic lathes, CNC walking machines, automatic slotting machines, rolling machines, continuous punching machines, drilling machines, milling machines, grinding machines ,High-end DMG 5-axis CNC machining equipment ,Mazak CNC turn-milling machine and other machining equipment,Hexagon three-dimensional coordinate measuring equipment and other high-end test equipment to ensure high machining accuracy, With senior design,R&D,machining and testing team, to provide perfect process solutions and modification suggestions. Welcome to long-term cooperation with us.

Introducing our high-precision EDM Machining parts, engineered to meet the most demanding specifications of modern industries. Utilizing advanced Electrical Discharge Machining technology, these parts are manufactured with unparalleled accuracy and surface finish, ideal for applications that require complex geometries and tight tolerances. Our components are produced from a variety of materials including hardened steels, exotic alloys, and conductive ceramics, ensuring optimal performance under extreme conditions.

Each part undergoes rigorous quality control processes to guarantee consistency and reliability. The EDM process allows for the creation of intricate shapes and fine details that traditional machining methods cannot achieve. This makes our parts perfect for aerospace, medical devices, automotive, and electronics industries.

Our commitment to innovation and precision ensures that every EDM machined part meets the highest standards of excellence. Whether you need prototypes or large-scale production, our state-of-the-art facilities and experienced team are ready to deliver. Choose our EDM Machining parts for superior quality and performance in your critical applications.

Send RFQ

Note: Please leave your email and our professionals will contact you as soon as possible!

Related Products