-

-

Aerospace

Provide efficient production and faster design delivery.

-

Automotive

Produce precision parts that exceed industry standards.

-

Automation

Quickly create and test products to push them to the market.

-

Consumer Products

Quickly push affordable new products to the market.

-

Electronics

Innovative casing for small batch production.

-

Industrial Equipment

Provide machines that can defeat competitors.

-

Energy Industry

Accelerate innovative development.

-

Medical Device

Build prototypes and products that comply with medical safety.

-

Robotics

Improve efficiency through precise, fast, and stable component quality.

-

Semiconductor

Shorten time to market through on-demand production.

-

-

-

About Us

Company Introduction, Our Corporate Culture and Development History And a professional and dedicated team.

-

Quality Assurance

Deliver high-quality parts that meet requirements and exceed expectations.

-

Our ability

Rapid prototyping and on-demand production.

-

News

Company news, industry trends, and technology sharing.

-

Vacuum cast parts

Our main products are yoga series, outdoor leisure series, sewing products series, plastic accessories series. We are professional manufacturer of EVA foam roller, PE foam roller, ankle weight, sports belt, massage bar, hula hoop, dumbbell and kettlebell.

Key words:

DiVona

Detailed

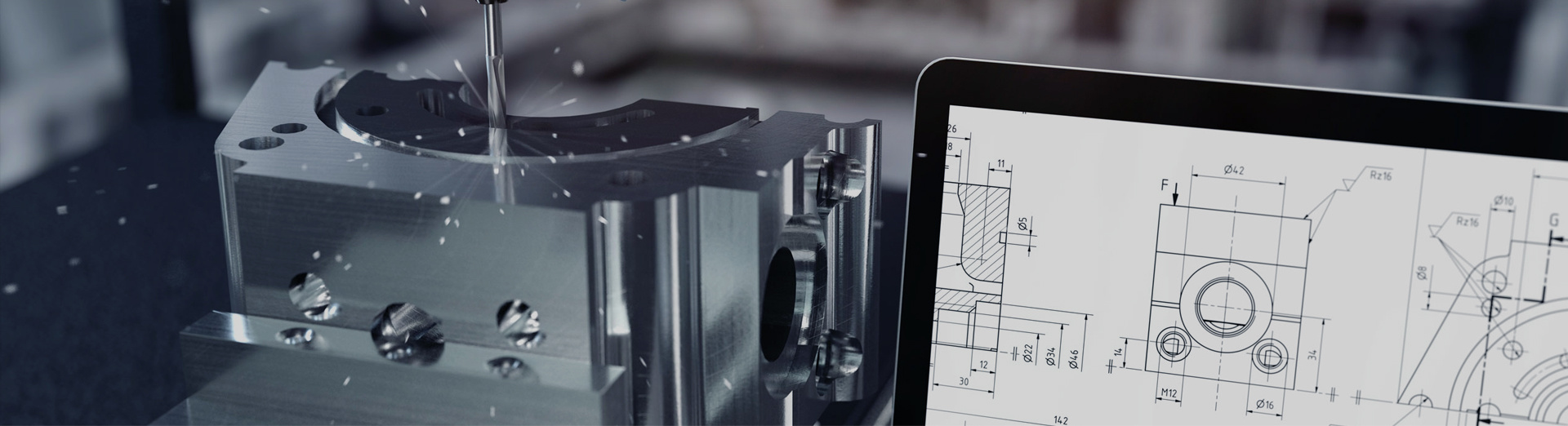

At Youxinda, our CNC milling services offer a wide range of materials to ensure precision and durability. This wide selection enables our customers to provide the choice for their projects, thereby improving the quality and performance of their products.

On demand CNC milling services for rapid prototyping and production parts. Obtain customized milling parts made of various high-quality metals and plastics.

Instant CNC quotation and free DFM

A strict tolerance of 0.01 millimeters

The fastest milling time for parts is 1 day

3. 4. 5-axis milling

一、真空铸造工艺简介

真空铸造是一种先进的金属铸造工艺,主要在高温环境下进行。该工艺利用真空环境来优化金属液体的流动与分布,从而提高铸件的质量和性能。其核心步骤包括模具准备、熔化金属、真空环境创建、金属液体注入模具以及冷却与后期处理。

二、真空铸造零件的特点

1. 高精度:真空铸造可以生产出高精度的零件,其尺寸精度和表面质量均优于传统铸造工艺。

2. 高强度:由于金属在真空环境下结晶,铸件的组织结构更加致密,因此具有更高的机械性能。

3. 优异的耐腐蚀性:真空铸造能消除铸件中的气孔和杂质,提高铸件的致密性和耐腐蚀性。

4. 广泛的材料选择:适用于多种金属材料,包括钢、铝、铜等。

三、真空铸造零件的应用

真空铸造零件广泛应用于汽车、航空、能源、电子、医疗等领域。例如,汽车发动机零部件、航空航天器的结构件、能源设备的关键部件等,均可以采用真空铸造工艺生产。

四、真空铸造的优势

1. 提高生产效率:真空铸造工艺可以实现自动化生产,提高生产效率。

2. 节能环保:与传统铸造工艺相比,真空铸造的能耗更低,减少废气、废水的排放,更加环保。

3. 降低

Send RFQ

Note: Please leave your email and our professionals will contact you as soon as possible!

Related Products

Contact Us

Room 201, No.1, Donglongxing Science Park, Huining Road, Xinshi Community, Dalang Street, Longhua District, Shenzhen

SAF Coolest v1.3 设置面板 BGMSX-ZDUO-MVSZE-ZES

无数据提示

Sorry, the current column has no content!