-

-

Aerospace

Provide efficient production and faster design delivery.

-

Automotive

Produce precision parts that exceed industry standards.

-

Automation

Quickly create and test products to push them to the market.

-

Consumer Products

Quickly push affordable new products to the market.

-

Electronics

Innovative casing for small batch production.

-

Industrial Equipment

Provide machines that can defeat competitors.

-

Energy Industry

Accelerate innovative development.

-

Medical Device

Build prototypes and products that comply with medical safety.

-

Robotics

Improve efficiency through precise, fast, and stable component quality.

-

Semiconductor

Shorten time to market through on-demand production.

-

-

-

About Us

Company Introduction, Our Corporate Culture and Development History And a professional and dedicated team.

-

Quality Assurance

Deliver high-quality parts that meet requirements and exceed expectations.

-

Our ability

Rapid prototyping and on-demand production.

-

News

Company news, industry trends, and technology sharing.

-

Precision five axis machining parts

Our main products are yoga series, outdoor leisure series, sewing products series, plastic accessories series. We are professional manufacturer of EVA foam roller, PE foam roller, ankle weight, sports belt, massage bar, hula hoop, dumbbell and kettlebell.

Key words:

DiVona

Detailed

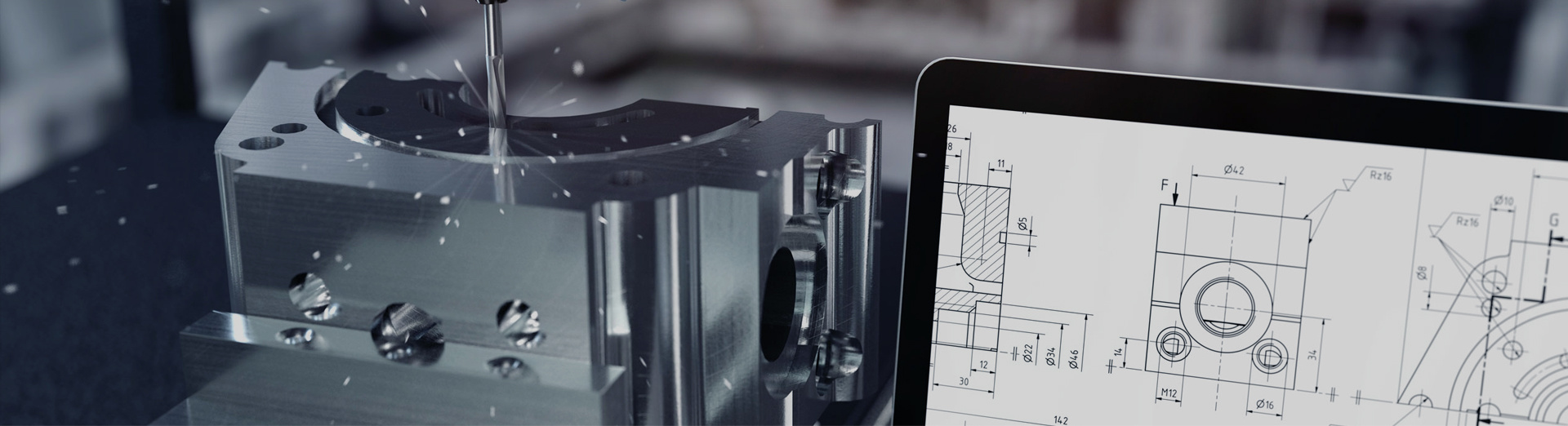

At Youxinda, our CNC milling services offer a wide range of materials to ensure precision and durability. This wide selection enables our customers to provide the choice for their projects, thereby improving the quality and performance of their products.

On demand CNC milling services for rapid prototyping and production parts. Obtain customized milling parts made of various high-quality metals and plastics.

Instant CNC quotation and free DFM

A strict tolerance of 0.01 millimeters

The fastest milling time for parts is 1 day

3. 4. 5-axis milling

Our precision five axis machining parts are engineered to meet the exacting demands of modern manufacturing and engineering applications. Leveraging advanced five-axis CNC technology, we deliver components with unparalleled complexity and precision, pushing the boundaries of what is achievable in machining.

Crafted from premium materials, our machining parts undergo rigorous quality inspections to ensure dimensional accuracy, surface finish perfection, and exceptional performance under varying operational conditions. With meticulous attention to detail and tight tolerances, our parts are manufactured to the highest industry standards, meeting the most stringent quality requirements.

Our skilled engineers and machinists bring extensive expertise to the table, capable of producing custom five axis machining parts tailored to specific design specifications. Whether you require prototypes, small production runs, or large-scale manufacturing, we are equipped to fulfill your needs with efficiency, precision, and competitive pricing.

The versatility of five-axis machining allows us to tackle complex geometries and intricate features with unparalleled accuracy and consistency. From aerospace components to medical devices and beyond, our precision parts excel in delivering the performance and reliability necessary for critical applications.

We are committed to innovation, quality, and customer satisfaction, striving to exceed expectations and provide solutions that drive success in diverse industries. Partner with us for your precision five axis machining part needs and discover the difference that excellence in manufacturing can make for your projects. Elevate your standards with our precision five axis machining parts and unlock new possibilities for your applications.

精密五轴加工是现代制造业中的一种高级工艺,尤其在航空、汽车、医疗和模具制造等领域有着广泛应用。这种加工方法涉及多个轴的同时运动,能够实现复杂形状和精细细节的加工。下面我们将详细介绍精密五轴加工零件的相关知识。

一、精密五轴加工概述

精密五轴加工是一种利用数控机床的五轴联动功能,对零件进行高精度、高效率的加工方法。五轴通常包括三个直线轴(X、Y、Z轴)和两个旋转轴(A、B或C轴)。这种加工方式能够实现复杂的空间运动和轨迹控制,从而完成高精度的零件加工。

二、精密五轴加工零件的重要性

1. 高精度:五轴加工能够实现亚微米级的精度,满足高端领域对零件精度的要求。

2. 复杂形状:五轴加工能够完成复杂曲面、凹槽等形状的加工,适用于模具、航空零件等制造。

3. 高效率:相比传统加工方式,五轴加工能够减少加工时间,提高生产效率。

三、精密五轴加工流程

1. 零件设计:根据需求进行零件设计,确保设计符合五轴加工的要求。

2. 数控编程:利用专业的数控编程软件,制定加工路径和参数。

3. 加工准备:选择合适的刀具、夹具等,进行加工前的准备工作。

4. 五轴加工:将零件放置在机床上,进行五轴联动加工。

5. 质量检测:对加工完成的零件进行质量检测,确保符合设计要求。

四、结语

精密五轴加工是现代制造业中不可或缺的一种工艺。随着科技的发展,五轴加工将在更多领域得到应用,提高零件的加工精度和效率。对于长度600mm的零件,五轴加工能够确保其精度和质量,满足高端领域的需求。同时,精密五轴加工对于提高产品质量、降低生产成本、推动产业升级具有重要意义。

Send RFQ

Note: Please leave your email and our professionals will contact you as soon as possible!

Related Products

Contact Us

Room 201, No.1, Donglongxing Science Park, Huining Road, Xinshi Community, Dalang Street, Longhua District, Shenzhen

SAF Coolest v1.3 设置面板 BGMSX-ZDUO-MVSZE-ZES

无数据提示

Sorry, the current column has no content!