-

-

Aerospace

Provide efficient production and faster design delivery.

-

Automotive

Produce precision parts that exceed industry standards.

-

Automation

Quickly create and test products to push them to the market.

-

Consumer Products

Quickly push affordable new products to the market.

-

Electronics

Innovative casing for small batch production.

-

Industrial Equipment

Provide machines that can defeat competitors.

-

Energy Industry

Accelerate innovative development.

-

Medical Device

Build prototypes and products that comply with medical safety.

-

Robotics

Improve efficiency through precise, fast, and stable component quality.

-

Semiconductor

Shorten time to market through on-demand production.

-

-

-

About Us

Company Introduction, Our Corporate Culture and Development History And a professional and dedicated team.

-

Quality Assurance

Deliver high-quality parts that meet requirements and exceed expectations.

-

Our ability

Rapid prototyping and on-demand production.

-

News

Company news, industry trends, and technology sharing.

-

CNC turning parts

Our main products are yoga series, outdoor leisure series, sewing products series, plastic accessories series. We are professional manufacturer of EVA foam roller, PE foam roller, ankle weight, sports belt, massage bar, hula hoop, dumbbell and kettlebell.

Key words:

DiVona

Detailed

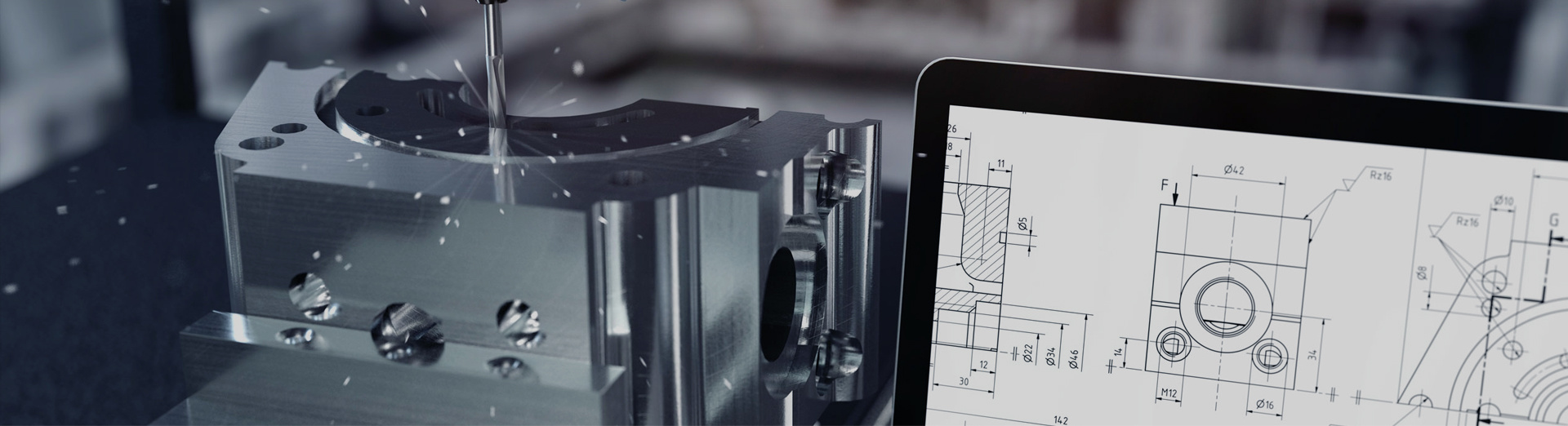

At Youxinda, our CNC milling services offer a wide range of materials to ensure precision and durability. This wide selection enables our customers to provide the choice for their projects, thereby improving the quality and performance of their products.

On demand CNC milling services for rapid prototyping and production parts. Obtain customized milling parts made of various high-quality metals and plastics.

Instant CNC quotation and free DFM

A strict tolerance of 0.01 millimeters

The fastest milling time for parts is 1 day

3. 4. 5-axis milling

CNC turning parts is a crucial part of the manufacturing industry, especially in the field of parts processing, where its role is irreplaceable. When we talk about CNC turning a part with a length of 600mm, the technical points and practical experience involved behind it are worth exploring in depth.

1、 Principles of CNC Turning

CNC turning, in short, is the precise cutting process achieved through computer-controlled lathes. Its core is a CNC machine tool, which controls the motion trajectory of the cutting tool through preset program instructions, thereby achieving precise machining of parts.

2、 Part turning process

For parts with a length of 600mm, the turning process is roughly as follows:

1. Design phase: Based on part requirements, carry out drawing design and process planning.

2. Raw material preparation: Select suitable raw materials to ensure their quality meets processing requirements.

3. Programming stage: According to the design drawings, use CNC programming software to write machining programs.

4. Processing stage: Input the written program into the CNC machine tool for part cutting.

5. Inspection and correction: Inspect the processed parts and correct any parts that do not meet the requirements.

3、 Technical points

1. Precision control: The key to CNC turning lies in precision control, including tool selection, cutting parameter settings, etc.

2. Programming skills: Programming is an important part of CNC turning, and proficient programming skills can greatly improve machining efficiency.

3. Quality control: From raw materials to finished products, every step must be strictly controlled to ensure the quality of the parts.

4、 Factors to consider in practice

1. Equipment condition: The maintenance and upkeep of CNC machine tools are crucial, and the good condition of the equipment is a prerequisite for processing.

2. Operational skills: The skill level of the operator directly affects the processing effect.

3. Cost control: While pursuing high quality, cost should also be considered, including raw material costs, labor costs, etc.

5、 Conclusion

CNC turning of parts, especially those with a length of 600mm, requires comprehensive consideration of various factors such as technology, equipment, and personnel. With the advancement of technology, CNC turning technology is also constantly developing, and there will be more innovations and applications in the future. For manufacturing practitioners, mastering CNC turning technology is an essential skill to adapt to the development of modern manufacturing industry.

Send RFQ

Note: Please leave your email and our professionals will contact you as soon as possible!

Related Products

Contact Us

Room 201, No.1, Donglongxing Science Park, Huining Road, Xinshi Community, Dalang Street, Longhua District, Shenzhen

SAF Coolest v1.3 设置面板 BGMSX-ZDUO-MVSZE-ZES

无数据提示

Sorry, the current column has no content!