OEM Stainless Steel Turning Machining Parts Factory

Our main products are yoga series, outdoor leisure series, sewing products series, plastic accessories series. We are professional manufacturer of EVA foam roller, PE foam roller, ankle weight, sports belt, massage bar, hula hoop, dumbbell and kettlebell.

Key words:

DiVona

Detailed

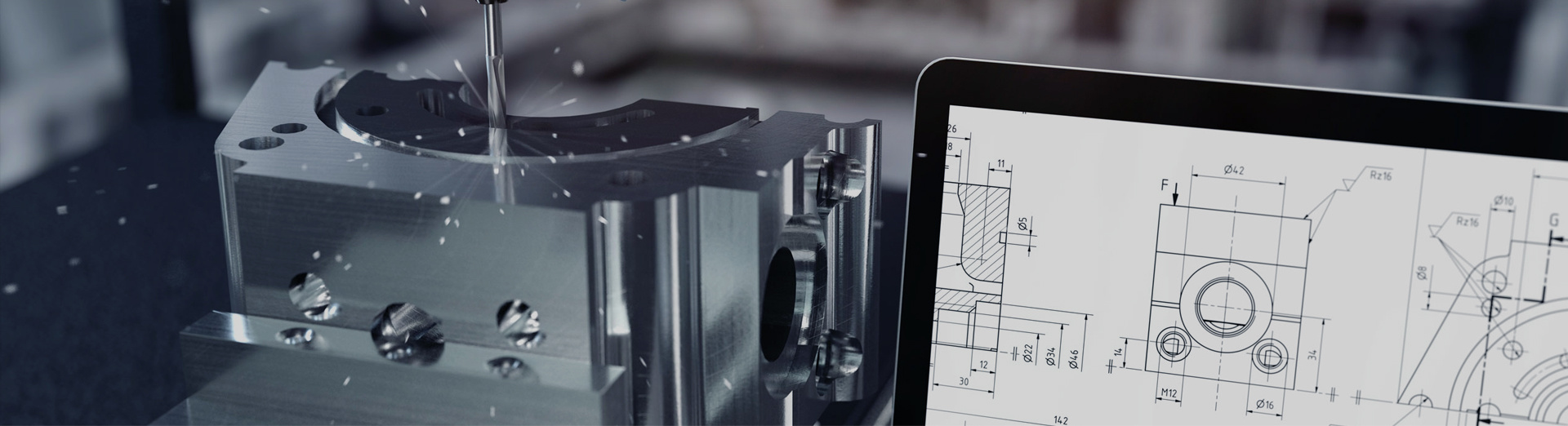

At Youxinda, our CNC milling services offer a wide range of materials to ensure precision and durability. This wide selection enables our customers to provide the choice for their projects, thereby improving the quality and performance of their products.

On demand CNC milling services for rapid prototyping and production parts. Obtain customized milling parts made of various high-quality metals and plastics.

Instant CNC quotation and free DFM

A strict tolerance of 0.01 millimeters

The fastest milling time for parts is 1 day

3. 4. 5-axis milling

OEM Stainless Steel Turning Machining Parts Factory

High-precision CNC turning parts have the characteristics of high precision, which can process accurate diametersand reasonable processing depths.With the wide application of precision rapid prototyping in various fields, therequirement is higher and higher. t is not only required to look good on the surface, but also higher quality.That's what we're working towards

Product Description

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless Steel, SteelAlloys,Plastic,ect. |

| Product Size | Customized size |

| Product Color | Customized Color |

| Tolerance | Tolerance refer to ISO2768-m, high precision achieve: ±0.005mm |

| Surface Treatment | Customized surface finishing,Plating (Zinc Plating, Nickel lating,Chrome Plating,etc),SandblastingAnodized with different color (Clear Anodized,Black ANodized,etc), Brushing, Polishing,Passivation.Powder Coating, Satin, polishing, Etching, Phosphating, Electrophoresis ect. |

| Heat treatment | Customized heat treatment |

| Drawing Format | 2D (PDF.DWG.DXF) /3D ( IGS,STPSTEP.XT) etc |

| MOQ | Accept small order,please feel free to contact us for further inquiry |

| Service | We will answer your email or inquiry within 12 hours. |

| Packing |

Inner packaging:PP bag,bubble bag, plastic wrap, foam etc. Outer packaging:strong carbon box, wooden case, pallet etc. |

| Delivery |

DHL, FEDEX, UPS, TNT, EMS, by air ,by sea or according to customers′ requirement |

| Application | Automotive, Automation, Test systems, Sensors, Medical,Sports,Consumer, Home appliance, Electronic , Pumps, Computers, Power and energy, Architecture, Printing, Food, Textile machinery,Optical,Lighting, Security and safety, AOI, SMT equipment, etc. |

OEM Service CNC Turning Parts are manufactured by CNC turning processing. It is mainly through rotating cylindrical blanks, and the tool is fed along the axial direction, so as to process precise diameters and reasonable processing depths. Turning has high processing efficiency and low equipment investment cost, which can make the parts obtain good overall processing accuracy.

Our CNC turning center equipment has a precision measurement of +/-0.005mm, producing parts with higher quality

YXD is a professional CNC turning parts supplier with more than 20 years of OEM service. We are always committed to providing the best solutions for our customers. We strive to exceed customer expectations in all aspects of the manufacturing process, and constantly update advanced production equipment to improve efficiency and processing accuracy, to ensure high and stable quality

Once you get in touch with us, we will work together to find the best process for completing your project and create a plan based on your budget and time. Please feel free and contact us for quotation.

CNC Turning Anodizing Parts are high-precision components that are manufactured through advanced CNC (Computer Numerical Control) turning processes and then enhanced with anodizing treatment. This combination ensures superior performance and durability for a variety of applications. The CNC turning process allows for intricate, accurate machining of parts from a wide range of materials, including aluminum, stainless steel, and titanium. Once the parts are turned to their exact specifications, they undergo anodizing, a process that increases the thickness of the natural oxide layer on the metal’s surface.

Anodizing not only improves the material’s corrosion resistance but also enhances wear and scratch resistance, extending the lifespan of the parts. Additionally, anodized parts exhibit improved electrical insulation properties and can be dyed in various colors, providing both functional and aesthetic benefits. CNC turning anodizing parts are widely used in industries such as aerospace, automotive, electronics, and medical devices, where high-quality, durable, and precise components are essential.

The Cnc Turning Anodizing Parts are ideal for critical applications that require a high level of reliability and performance, offering excellent resistance to environmental factors such as heat, moisture, and chemicals. With the combination of CNC turning and anodizing, you get components that are both technically advanced and visually appealing, ensuring a competitive edge in your industry.

Send RFQ

Note: Please leave your email and our professionals will contact you as soon as possible!

Related Products