-

-

Aerospace

Provide efficient production and faster design delivery.

-

Automotive

Produce precision parts that exceed industry standards.

-

Automation

Quickly create and test products to push them to the market.

-

Consumer Products

Quickly push affordable new products to the market.

-

Electronics

Innovative casing for small batch production.

-

Industrial Equipment

Provide machines that can defeat competitors.

-

Energy Industry

Accelerate innovative development.

-

Medical Device

Build prototypes and products that comply with medical safety.

-

Robotics

Improve efficiency through precise, fast, and stable component quality.

-

Semiconductor

Shorten time to market through on-demand production.

-

-

-

About Us

Company Introduction, Our Corporate Culture and Development History And a professional and dedicated team.

-

Quality Assurance

Deliver high-quality parts that meet requirements and exceed expectations.

-

Our ability

Rapid prototyping and on-demand production.

-

News

Company news, industry trends, and technology sharing.

-

3D printed parts

Our main products are yoga series, outdoor leisure series, sewing products series, plastic accessories series. We are professional manufacturer of EVA foam roller, PE foam roller, ankle weight, sports belt, massage bar, hula hoop, dumbbell and kettlebell.

Key words:

DiVona

Detailed

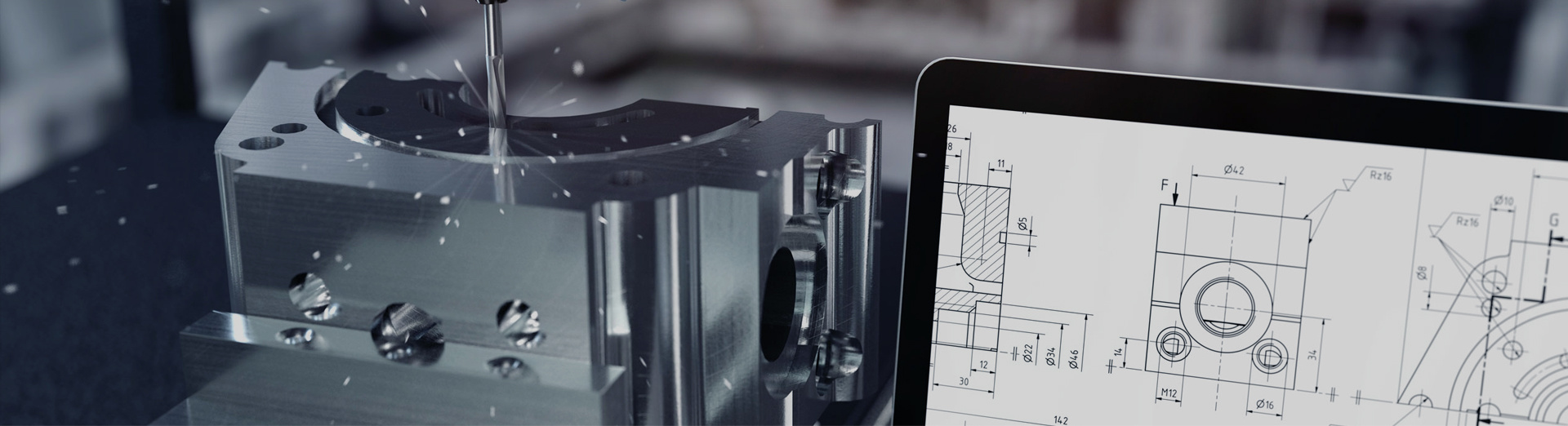

At Youxinda, our CNC milling services offer a wide range of materials to ensure precision and durability. This wide selection enables our customers to provide the choice for their projects, thereby improving the quality and performance of their products.

On demand CNC milling services for rapid prototyping and production parts. Obtain customized milling parts made of various high-quality metals and plastics.

Instant CNC quotation and free DFM

A strict tolerance of 0.01 millimeters

The fastest milling time for parts is 1 day

3. 4. 5-axis milling

3D printed parts, also known as additive manufacturing, is a technology that creates three-dimensional solids by stacking materials layer by layer. Unlike traditional subtraction manufacturing, 3D printing technology can stack powders, liquids, or other materials layer by layer based on a pre designed digital model, ultimately generating solid parts. The advantages of this technology are the ability to manufacture complex shapes and structures without assembly, and high material utilization.

Choosing the appropriate material is crucial when 3D printing parts. Common printing materials include plastics, metals, ceramics, and biomaterials. According to the application scenario and requirements of the parts, suitable materials can be selected for printing. For example, plastic materials are suitable for prototyping and functional testing; Metal materials are suitable for manufacturing high-strength and wear-resistant parts.

Before 3D printing, it is necessary to design a digital model of the part. This step can be completed using computer-aided design software. During the design process, factors such as the practicality of the parts, structural strength, and material utilization need to be considered. After the design is completed, the model can be imported into a 3D printer for printing.

After importing the designed model into a 3D printer, the machine will stack materials layer by layer according to the model's instructions, ultimately generating solid parts. After printing, post-processing may be required, such as polishing, coloring, heat treatment, etc., to ensure that the parts meet the final application requirements.

3D printing technology has a wide range of applications in many fields, such as aerospace, automotive manufacturing, medical equipment, construction, etc. With the continuous advancement of technology, the application scope of 3D printed parts will further expand.

In short, 3D printing technology has brought revolutionary changes to the manufacturing industry. By understanding 3D printing technology, selecting appropriate materials, designing part models, and printing and post-processing, we can easily create various complex parts, providing strong support for the development of various industries.

Send RFQ

Note: Please leave your email and our professionals will contact you as soon as possible!

Related Products

Contact Us

Room 201, No.1, Donglongxing Science Park, Huining Road, Xinshi Community, Dalang Street, Longhua District, Shenzhen

SAF Coolest v1.3 设置面板 BGMSX-ZDUO-MVSZE-ZES

无数据提示

Sorry, the current column has no content!