High Quality CNC Turning Anodizing Parts

Our main products are yoga series, outdoor leisure series, sewing products series, plastic accessories series. We are professional manufacturer of EVA foam roller, PE foam roller, ankle weight, sports belt, massage bar, hula hoop, dumbbell and kettlebell.

Key words:

DiVona

Detailed

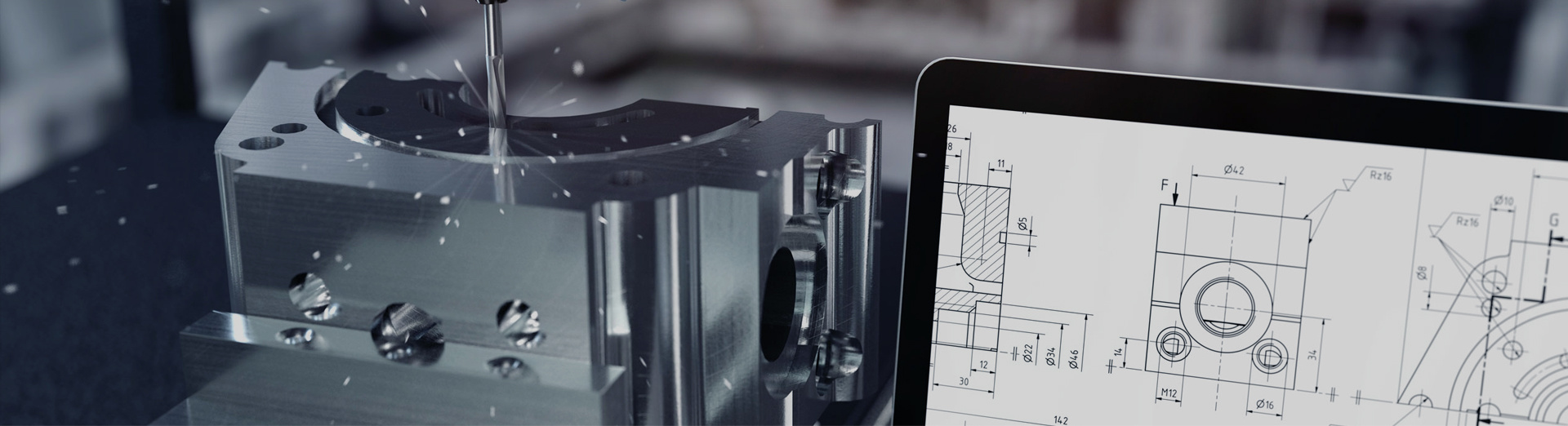

At Youxinda, our CNC milling services offer a wide range of materials to ensure precision and durability. This wide selection enables our customers to provide the choice for their projects, thereby improving the quality and performance of their products.

On demand CNC milling services for rapid prototyping and production parts. Obtain customized milling parts made of various high-quality metals and plastics.

Instant CNC quotation and free DFM

A strict tolerance of 0.01 millimeters

The fastest milling time for parts is 1 day

3. 4. 5-axis milling

High Quality CNC Turning Anodizing Parts

YXD Company is SO9001:2015 certified enterprise, specializing in the design and manufacture of various clampsclamps tools, foam clamps. CNC turning parts are mainly made of aluminum, carbon steel, alloy steel, plastic andso on through turning, milling and CNC processing. We have rich manufacturing experience and machiningservices, 3/4/5 axis CNC machining services, CNC turning services, CNC miling services, CNC turn-millingcompound and other machining services

Product Description

| Product Name | Lathe Machine CNC Turning Machining Parts |

| CNC Machining or Not | CNC Machining |

| Micro Machining or Not | Micro Machining |

| Model Number | CNC Truning |

| Processing way | CNC Turning, CNC Milling, CNC Turn-milling,Laser Cutting, Bending, Spinning, Wire Cutting, Stamping, Electric Discharge Machining (EDM), Injection Molding |

| Tolerance | ISO2768-m or refer to customer's request. |

| Surface Treatment | Plating (Zinc Plating, Nickel Plating,Chrome Plating,etc),Sandblasting, Anodized with different color(Clear Anodized,Black ANodized,etc), Brushing, Polishing,Passivation, Powder Coating, Satin,polishing, Etching, Phosphating, Electrophoresis ect. |

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless,Steel, Steel Alloys,Plastic,ect. |

| MOQ | 1pc |

| Lead time | 3-5days |

| Drawing Format | jpg/.pdf/.dxf/.dwg/.igs./.stp/x t. etc |

| Application | Automotive, Automation, Test systems, Sensors, Medical,Sports,Consumer, Home appliance, Electronic , Pumps, Computers, Power and energy, Architecture, Printing, Food, Textile machinery,Optical,Lighting, Security and safety, AOI, SMT equipment, etc. |

| Our Certification |

37 Software Copyrights (Rapid Prototype/3D Printing) 15 Patent Licensing (Utility Model Invention ) 12 Patent Licensing (Invention) ISO9001:2015 National High-tech Enterprises Certified by National |

| Our Advantages |

20 years experience Mass production service High machining precision Professional machining and testing equipment 99.8% qualified for finished products Manufacturer competitive price 80+ professional R&D engineers team 120+ advanced professional machining and testing equipment |

CNC Turning Anodizing Parts are precision-engineered components that undergo a specialized anodizing process to enhance their surface properties. These parts are produced using Computer Numerical Control (CNC) turning technology, which ensures high accuracy and repeatability. The anodizing process creates a durable, protective oxide layer on the surface of the parts, improving their resistance to corrosion, abrasion, and fading.

Our CNC Turning Anodizing Parts can be customized according to your specific requirements. We offer a wide range of materials, including aluminum, copper, and steel, to meet the diverse needs of different industries. Whether you need small intricate parts or large-scale components, we have the capabilities to produce them to exact specifications.

The manufacturing process of our CNC Turning Anodizing Parts involves several steps. The first step is to select the appropriate material based on the intended application. The material is then loaded onto a CNC turning machine, where it is precisely machined to the desired shape and dimensions. After machining, the parts undergo anodizing treatment, which involves immersing them in an electrolytic bath to create the oxide layer.

Applications of CNC Turning Anodizing Parts include aerospace, automotive, electronics, medical, and industrial equipment. These parts are used in various components such as gears, shafts, connectors, and housings, where durability and performance are crucial.

In conclusion, our CNC Turning Anodizing Parts offer a reliable and cost-effective solution for your manufacturing needs. With high precision, customizable options, and excellent surface properties, these parts are ideal for a wide range of applications. Contact us today to learn more about our capabilities and how we can assist you with your specific requirements.

Send RFQ

Note: Please leave your email and our professionals will contact you as soon as possible!

Related Products