OEM Stainless Steel Turning Machining Parts Factory

Our main products are yoga series, outdoor leisure series, sewing products series, plastic accessories series. We are professional manufacturer of EVA foam roller, PE foam roller, ankle weight, sports belt, massage bar, hula hoop, dumbbell and kettlebell.

Key words:

DiVona

Detailed

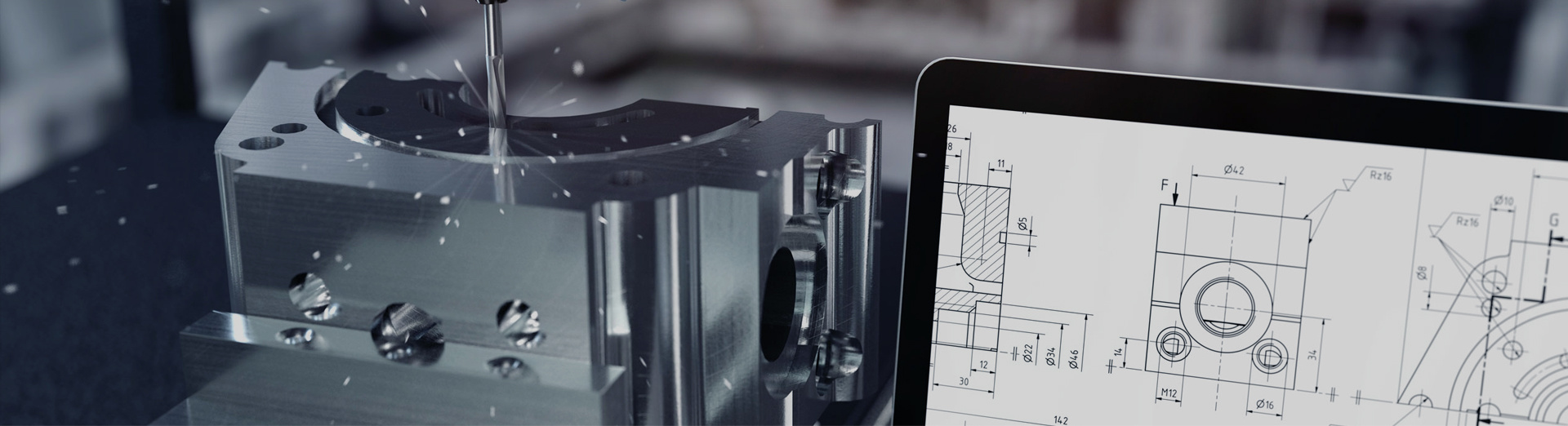

At Youxinda, our CNC milling services offer a wide range of materials to ensure precision and durability. This wide selection enables our customers to provide the choice for their projects, thereby improving the quality and performance of their products.

On demand CNC milling services for rapid prototyping and production parts. Obtain customized milling parts made of various high-quality metals and plastics.

Instant CNC quotation and free DFM

A strict tolerance of 0.01 millimeters

The fastest milling time for parts is 1 day

3. 4. 5-axis milling

OEM Stainless Steel Turning Machining Parts Factory

High-precision CNC turning parts have the characteristics of high precision, which can process accurate diametersand reasonable processing depths.With the wide application of precision rapid prototyping in various fields, thereguirement is higher and higher. lt is not only required to look good on the surface, but also higher guality.That's what we're working towards.

Product Description

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless Steel, Steel Alloys,Plastic,ect. |

| Product Size | Customized Size |

| Product Color | Customized Color |

| Tolerance | Tolerance refer to ISO2768-m, high precision achieve: ±0.005mm |

| Surface Treatment | Customized surface finishing,Plating (Zinc Plating, Nickel lating,Chrome Plating,etc),SandblastingAnodized with different color (Clear Anodized,Black ANodized,etc), Brushing, Polishing,Passivation.Powder Coating, Satin, polishing, Etching, Phosphating, Electrophoresis ect. |

| Heat treatment | Customized heat treatment |

| Drawing Format | 2D (PDF.DWG.DXF) /3D ( IGS,STPSTEP.XT) etc |

| MOQ | Accept small order,please feel free to contact us for further inquiry |

| Service | We will answer your email or inquiry within 12 hours. |

| Packing |

Inner packaging:PP bag,bubble bag, plastic wrap, foam etc. Outer packaging:strong carbon box, wooden case, pallet etc. |

| Delivery |

DHL, FEDEX, UPS, TNT, EMS, by air ,by sea or according to customers′ requirement |

| Application | Automotive, Automation, Test systems, Sensors, Medical,Sports,Consumer, Home appliance, Electronic , Pumps, Computers, Power and energy, Architecture, Printing, Food, Textile machinery,Optical,Lighting, Security and safety, AOI, SMT equipment, etc. |

OEM Service CNC Turning Parts are manufactured by CNC turning processing. It is mainly through rotating cylindrical blanks, and the tool is fed along the axial direction, so as to process precise diameters and reasonable processing depths. Turning has high processing efficiency and low equipment investment cost, which can make the parts obtain good overall processing accuracy.

Our CNC turning center equipment has a precision measurement of +/-0.005mm, producing parts with higher quality

YXD is a professional CNC turning parts supplier with more than 20 years of OEM service. We are always committed to providing the best solutions for our customers. We strive to exceed customer expectations in all aspects of the manufacturing process, and constantly update advanced production equipment to improve efficiency and processing accuracy, to ensure high and stable quality

Once you get in touch with us, we will work together to find the best process for completing your project and create a plan based on your budget and time. Please feel free and contact us for quotation.

Stainless Steel Turning Machining Parts are highly sought-after components in various industries. These parts are crafted through precision turning machining processes specifically for stainless steel. Stainless steel offers excellent resistance to corrosion, making these parts durable and suitable for a wide range of environments. The turning machining process allows for the shaping of these parts with meticulous attention to detail and accuracy. Complex geometries and tight tolerances can be achieved, ensuring optimal performance and functionality.

The Stainless Steel Turning Machining Parts are known for their strength and rigidity, enabling them to handle heavy loads and stresses. They are often used in applications where reliability and longevity are crucial. Industries such as automotive, aerospace, marine, and medical benefit from the use of these high-quality parts. The surface finish of these parts is smooth and precise, enhancing their aesthetic appeal as well as their performance. They can be customized to meet specific design requirements and customer specifications. The manufacturing of Stainless Steel Turning Machining Parts involves advanced machinery and skilled technicians who ensure that each part is produced to the highest standards.

Quality control measures are in place to guarantee that the parts conform to all relevant standards and specifications. These parts play a vital role in assemblies and systems, providing stability and functionality. Their excellent mechanical properties and corrosion resistance make them an ideal choice for demanding applications. With Stainless Steel Turning Machining Parts, manufacturers and engineers can rely on reliable and high-performing components to drive their projects forward.

Send RFQ

Note: Please leave your email and our professionals will contact you as soon as possible!

Related Products