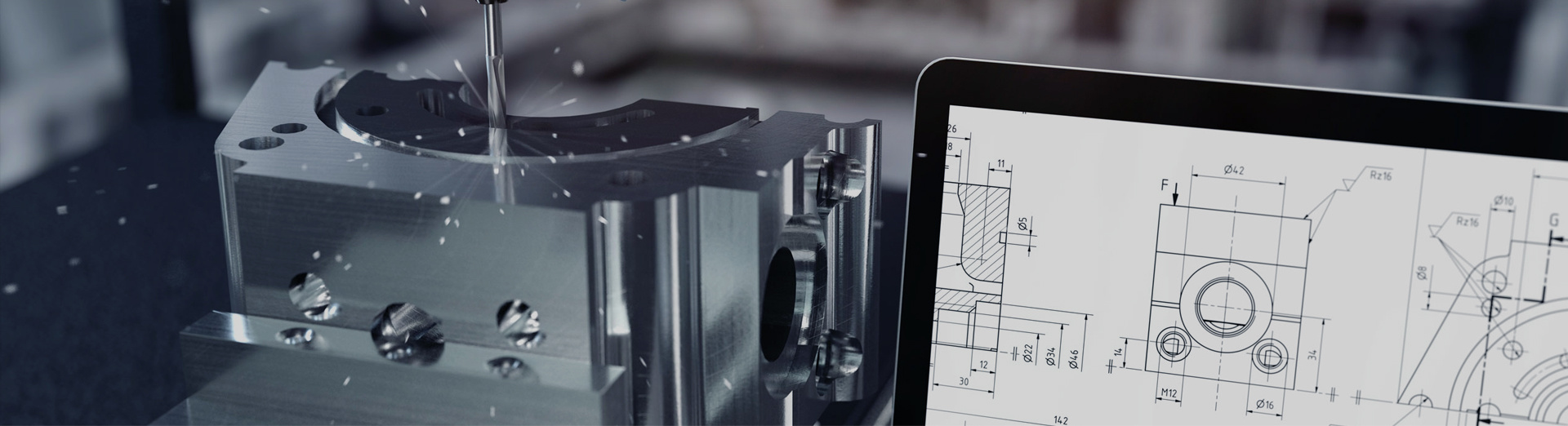

High Precision CNC Milling Parts

Our main products are yoga series, outdoor leisure series, sewing products series, plastic accessories series. We are professional manufacturer of EVA foam roller, PE foam roller, ankle weight, sports belt, massage bar, hula hoop, dumbbell and kettlebell.

Key words:

DiVona

Detailed

At Youxinda, our CNC milling services offer a wide range of materials to ensure precision and durability. This wide selection enables our customers to provide the choice for their projects, thereby improving the quality and performance of their products.

On demand CNC milling services for rapid prototyping and production parts. Obtain customized milling parts made of various high-quality metals and plastics.

Instant CNC quotation and free DFM

A strict tolerance of 0.01 millimeters

The fastest milling time for parts is 1 day

3. 4. 5-axis milling

High Precision CNC Milling Parts

CNC Machining Parts is available for 3/4/5 axis CNC machining, CNC turning machining, CNC milling machining, CNC turning and milling compound machining and other machining services. The process is suitable for processing a variety of materials, such as metals, plastics, wood, and manufacturing a variety of custom designed parts and products. For high-precision CNC milling parts, the processing is very strict. The processing procedures include feed and output. There are specific requirements for the size and accuracy.

Product Descriptions

| Model Number | CNC Truning |

| CNC Machining or Not | CNC Machining |

| Micro Machining or Not | Micro Machining |

| Processing Way | CNC Turning, CNC Milling,CNC Turn-milling, Laser Cutting, Bending, Spinning, Wire Cutting, Stamping, Electric Discharge Machining (EDM), Injection Molding |

| Tolerance | ISO2768-m or refer to customer's request. |

| Surface Treatment | Plating (Zinc Plating, Nickel Plating,Chrome Plating,etc),Sandblasting, Anodized with different color (Clear Anodized,Black ANodized,etc), Brushing, Polishing,Passivation, Powder Coating, Satin, polishing, Etching, Phosphating, Electrophoresis ect. |

| Type | Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping |

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless Steel, Steel Alloys,Plastic,ect. |

| MOQ | 1 pc |

| Lead time | 3-5 days |

| Drawing Format | 2D (PDF, DWG, DXF) /3D ( IGS, STP,STEP, XT) etc |

| Application | Automotive, Automation, Test systems, Sensors, Medical,Sports,Consumer, Home appliance, Electronic , Pumps, Computers, Power and energy, Architecture, Printing, Food, Textile machinery,Optical,Lighting, Security and safety, AOI, SMT equipment, etc. |

1 . All CNC miling parts produced according to your CAD and 3D drawings or sample. Please send the blueprint or drawing artwork firstly, we will offer our quotation to you within 8 hours.

2 . OEM&oDM are welcomed.

3 . Packing: Wooden cases, carton or on requirement.

4 . Main Machining equipment: Machining center, CNC, Lathe, Turning machine, Miling machine,Driling machine, internal and externagrinding machine, (ylindrical grinding machine, Tapping driling machine, Wire cutting machine Sheet metal machine , 3D printing machinfor metal /plastic, vacuum casting etc.

5 . Testing facility: Coordinate measuring machine, projector, roughness tester, hardness tester, concentricity tester. Height tester

6 . Part size: Diameter from 0.5mm to 150mm.

7 . Tolerance: +/-0.001mm.

8 . Minimum Order: Not setting , Comply with customer's demand.

9 . Delivery way: EXPRESS, BY SEA OR BY AIR on your requirement.

CNC Machining process

(1) According to the part loading and positioning method:

each part has different structural shapes, and the technical requirements of each surface are also different. Therefore, the positioning methods are different when processing, so the process can be divided according to different positioning methods;

(2) According to the rough and fine processing division process:

according to the processing precision, stiffness and deformation of the parts, the process can be divided according to the principle of coarse and fine machining, that is, roughing and finishing, at this time Can be processed with different machine tools or different tools;

(3) According to the tool division process:

In order to reduce the tool change time, compress the idle time and reduce the unnecessary positioning error, the parts can be processed according to the tool centralized process, that is, in one setup, use a tool as much as possible. Machining the parts that may be processed, and then replacing the other parts with another knife.

Our company is professional manufacturers for CNC machining service in China, with more than 20 year rich experience,specializes in custom CNC machining parts of aluminum, stainless steel, brass, copper, metal and plastic materials, mainly exported to Europe and the United States. CNC turning metal machining parts can be used in different fields. CNC turning metal machining parts are custom made, no inventory; We can produce according to your drawings or samples . We can sign NDA(Non-Disclosure Agreement) with you, small batch order is OK.Please feel free and contact us for more information.

High precision CNC milling of parts is a manufacturing process that utilizes computer numerical control (CNC) technology to create highly accurate and complex parts from various materials. This process offers several advantages over traditional manufacturing methods, including greater precision, efficiency, and repeatability.

The CNC milling process starts with the design of the part using specialized CAD (computer-aided design) software. The CAD file is then converted into a machine-readable code that instructs the CNC milling machine on how to move and cut the material to create the desired shape and dimensions of the part.

During the CNC milling process, the material is held in place by a clamping device while a rotating cutting tool is moved along the surface of the material to remove material and shape the part. The cutting tool can move in multiple axes, allowing for the creation of complex geometries and shapes.

One of the key benefits of high precision CNC milling is its ability to achieve very tight tolerances. This means that the dimensions and shape of the part can be controlled with a high degree of accuracy, ensuring that the part fits precisely into the larger assembly or device. In addition, CNC milling can produce parts with very smooth surfaces, reducing the need for additional finishing operations.

High precision CNC milling is widely used in a variety of industries, including aerospace, automotive, medical, and electronics. It is particularly useful for manufacturing small to medium-sized parts with complex geometries or tight tolerances. Some common applications of high precision CNC milling include the production of gears, shafts, brackets, housings, and connectors.

In conclusion, high precision CNC milling is a highly effective manufacturing process that offers many benefits for the production of complex and precise parts. Its versatility, accuracy, and efficiency make it an ideal choice for a wide range of industries and applications.

Send RFQ

Note: Please leave your email and our professionals will contact you as soon as possible!

Related Products